GET IN TOUCH

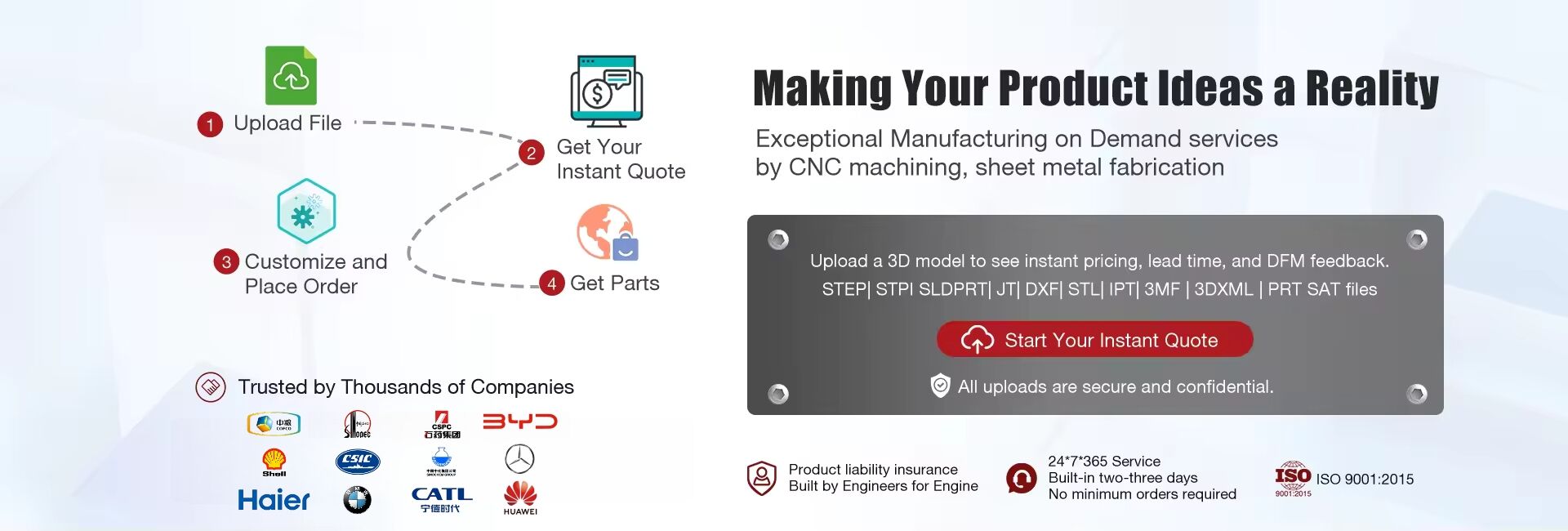

Sheet Metal Fabrication Services

Instant quotes on custom-formed sheet metal parts | Prototypes and production parts in days;| Drawings in 3 days, samples in 7 days | ISO and CE Certified Quality Assurance

✅ Factory-direct pricing (No middleman markup)

✅ Average quote response: 6-8 business hours

✅ Free DFM analysis included

✅ Material certification available

✅ MOQ: 1 piece for prototyping

✅ Bulk production discounts available

High-precision laser cutting for steel, stainless steel, aluminum, and sheet metal. Fast turnaround, competitive pricing, and comprehensive fabrication services.

Why Choose Our Laser Cutting Service:

15+ laser cutting machines (fiber, CO₂)

Cutting thickness: 0.5mm to 30mm

Positioning accuracy: ±0.03mm, Repeatability: ±0.02mm

24-hour rapid prototyping, 5-7 day production

Material optimization software reduces waste by 20%

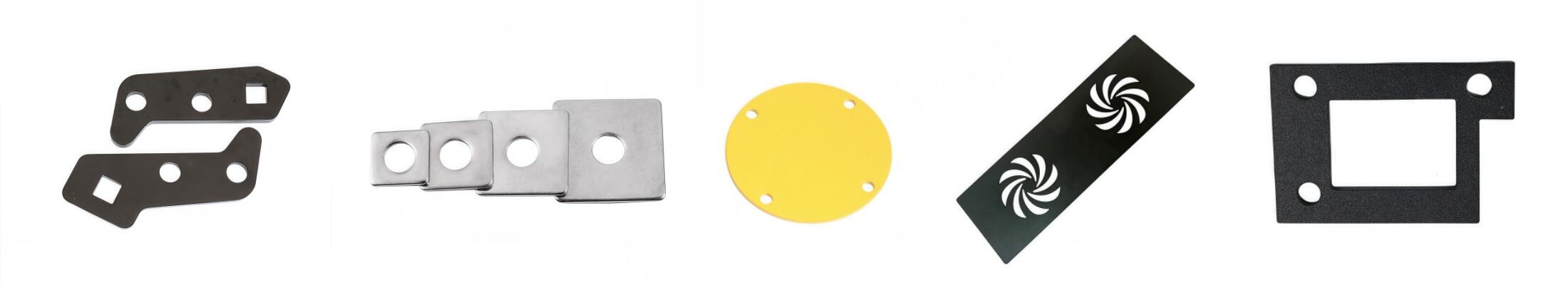

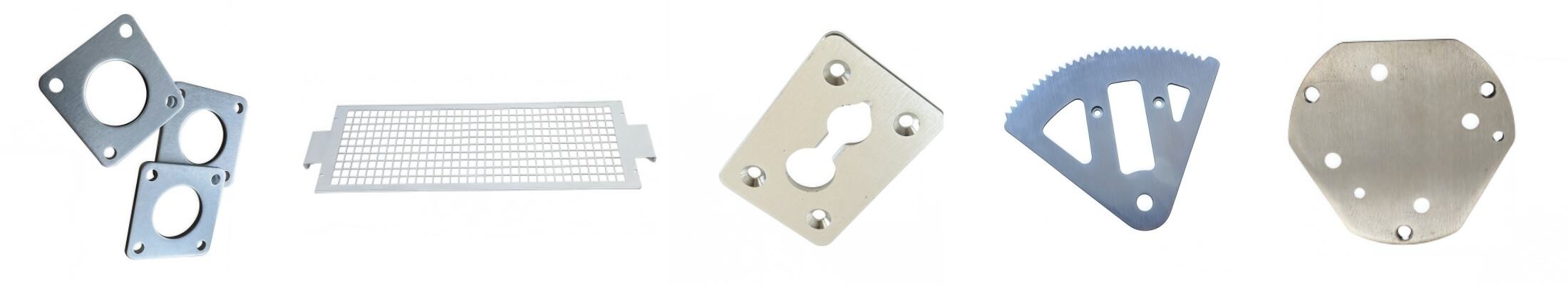

Custom Metal Laser Cutting Projects

Metal laser cutting service is a manufacturing process that uses a high-powered laser beam to cut and shape metal materials with extreme precision. The laser melts, burns, or vaporizes the material, creating clean and accurate cuts.DEEPLINK provide one-stop laser cutting service.

5kW fiber laser cutting machine: specially designed for precision thin plate processing, suitable for stainless steel (0.5-12mm), aluminum alloy (0.5-10mm) and other materials, with a cutting accuracy of ±0.05mm, meeting the needs of high-precision parts such as electronic components and medical devices.

6kW high-power laser cutting machine: can efficiently process medium and thick plates (carbon steel ≤25mm, stainless steel ≤18mm), with a 30% increase in cutting speed, suitable for mass production of engineering machinery, automotive structural parts, etc.

Intelligent Process Control

Equipped with top-level cutting head and automatic focusing system, it optimizes the focus position in real time to ensure that the cutting section of materials of different thicknesses is smooth and burr-free. It is also equipped with AI nesting software to maximize the utilization of plates ,In this way,DEEPLINK can help customers save costs in laser cutting service.

Professional Laser Cutting Service Factory: Advantages And Services

Flexible Project Size: We handle both small, detailed parts and large-scale production with equal efficiency, whether it’s a single prototype or a mass production order.

Cost Efficiency: Our cutting process reduces material waste, making it cost-effective for both small and large projects.

Precision Cutting: Our laser technology provides high accuracy and clean cuts, even for complex shapes and fine details. We ensure tight tolerances and minimal material deformation.

Consistency: Each part produced is consistent in quality, from the first to the last, ensuring reliable results for your project.

Material Versatility: We work with a wide range of metals, including stainless steel, aluminum, and carbon steel laser cutting service providing flexibility in material selection.

>> Learn More About The Materials Commonly Used for Metal Laser Cutting Service

Precision cutting for steel, stainless, aluminum, copper, brass, and titanium alloys.

Clean, burr-free aluminum cutting with minimal heat-affected zone, ideal for aerospace and electronics.

Thick plate cutting up to 30mm with high edge quality and minimal dross.

From single prototypes to production runs with consistent quality and tight tolerances.

Carbon steel, mild steel, and alloy steel cutting with precise edges and minimal distortion.

304, 316, 430 stainless steel cutting for medical, food processing, and architectural applications.

Versatile cutting for various metals including brass, copper, titanium, and specialty alloys.

Structural steel plate cutting for construction, machinery, and industrial applications.

Sheet cutting with mirror finish preservation and minimal thermal distortion.

Thin to medium gauge sheet metal cutting for enclosures, brackets, and components.

Heavy plate cutting with bevel edges for welding preparation.

Aluminum sheet and plate cutting with excellent edge quality for visible applications.

CNC-controlled laser cutting combined with punching, tapping, and bending services.

All aluminum series cutting with specialized parameters for optimal results.

1. Automotive Industry

Requirements: High precision, mass production capability, and the ability to handle complex shapes for lightweight, durable components.

Laser-Cut Components:

Exhaust systems

Chassis parts

Brackets

Heat shields

Body panels

2. Aerospace Industry

Requirements: Lightweight but strong materials like aluminum and titanium, precise cuts, and strict adherence to safety and regulatory standards.

Laser-Cut Components:

Aircraft panels

Turbine blades

Structural brackets

Precision enclosures

3. Electronics Industry

Requirements: High precision for small and intricate parts, clean edges, and materials with good conductivity or heat resistance.

Laser-Cut Components:

Enclosures for electronic devices

Heat sinks

Circuit board frames

Connectors

4. Medical/Healthcare Industry

Requirements: Use of biocompatible materials like stainless steel and titanium, precision cutting, and ensuring sterility through smooth finishes.

Laser-Cut Components:

Surgical instruments

Implants

Medical device enclosures

5. Energy Sector

Requirements: Durability, corrosion resistance, and ability to withstand environmental stresses while providing high-efficiency solutions.

Laser-Cut Components:

Solar panel frames

Wind turbine components

Battery housings

Heat exchangers

6. Industrial Equipment

Requirements: High durability and precision, often for thick materials, ensuring robust components for heavy-duty use.

Laser-Cut Components:

Machine frames

Custom brackets

Control panels

Equipment housings

Laser cutting is an advanced manufacturing process that uses a focused laser beam to cut, shape, or engrave various types of metal with extreme precision.High Precision,Versatility,Speed and Efficiency,Clean Edges,Minimal Material Distortion

Ready to Get Started? Contact Deeplink for Your Metal Custom Needs

If you’re interested in learning more about how laser cutting can benefit your project, feel free to contact us for personalized advice and explore how we can meet your specific needs.We’re here to help with expert guidance on all aspects of laser cutting service.

Quotation |

According to your drawing(size, material, thickness, processing content, and required technology, etc) and samples |

Material |

Carbon steel, SPCC, SGCC, Stainless Steel, Aluminum, Brass, Copper, etc. |

Processing |

Laser Cutting, Bending, Precision Stamping, CNC Punching, Threading, Riveting, Drilling, Welding etc. |

Surface Treatment |

Brushing, Polishing, Anodizing, Powder Coating, Electroplating, Silk-screen Printing, Sandblasting, etc. |

Tolerance

|

Laser cutting: ±0.1mm |

Bending: ±0.2~0.5mm | |

Precision Stamping: ±0.02~±0.05mm | |

Logo |

Silk-screen Printing, Laser Engraving |

Size |

Accept custom size. |

Color |

White, Black, Silver, Red, Grey, Pantone and RAL, etc. |

Drawing format |

DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft. |

Sample lead time |

Without surface treatment 1-3 working days; Required surface treatment 3-5 working days. |

Pricing Term |

DAP, DDP, EXW, FCA, FOB, CIF, etc. |

Payment term |

Sample: 100% payment before production Mass production: (30% in advance as deposit, balance before shipment) |

Certificate |

ISO9001:2015/SGS/TUV/RoHS |

Packing |

By PE bag/EPE foam/custom box/poly wood box or as your request. |

GET IN TOUCH

Sheet Metal Fabrication Services

Instant quotes on custom-formed sheet metal parts | Prototypes and production parts in days;| Drawings in 3 days, samples in 7 days | ISO and CE Certified Quality Assurance