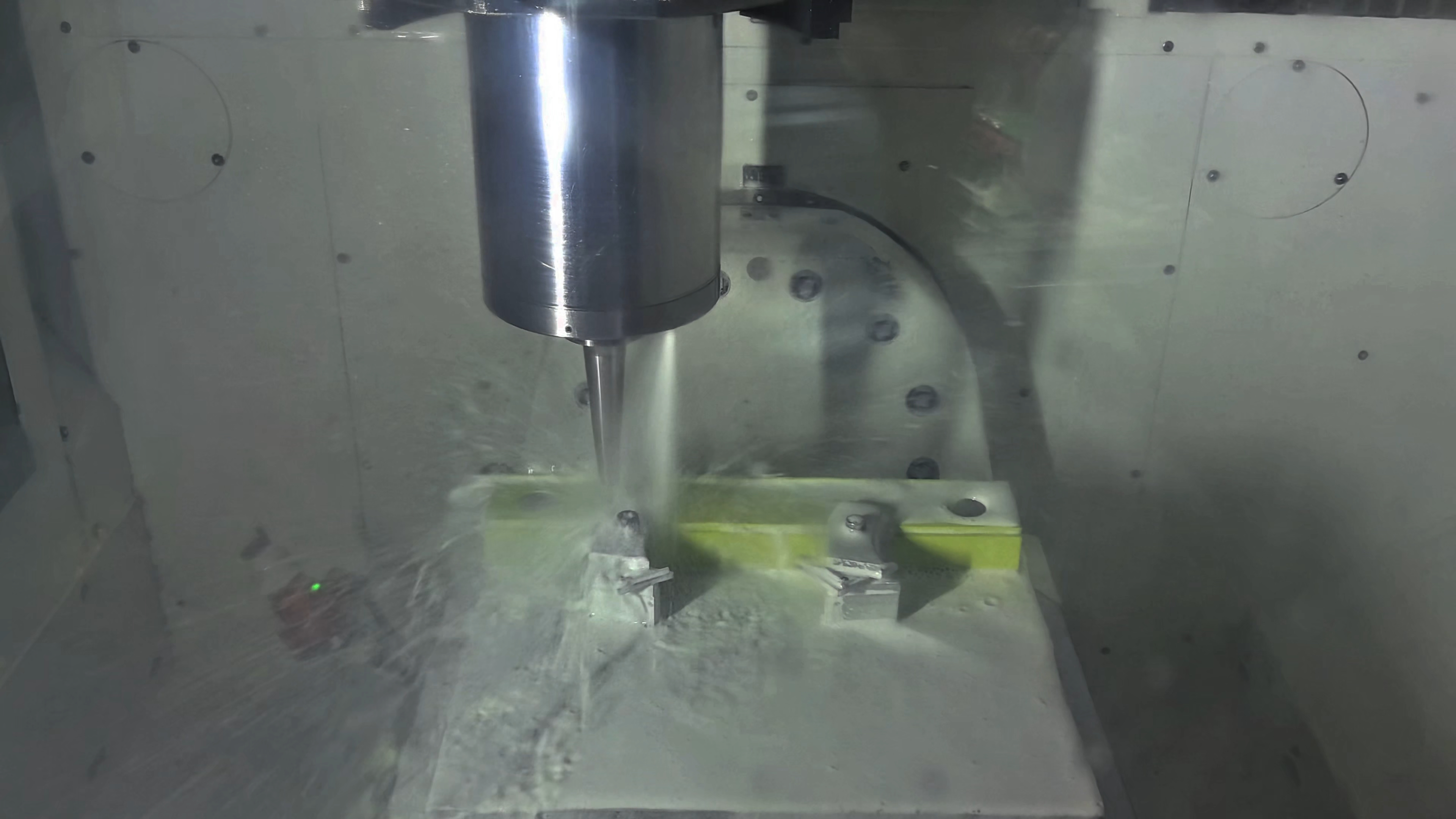

Understanding Precision, Accuracy, and Tolerances in CNC Machining Parts

Defining Precision vs. Accuracy in CNC Machining Parts

When talking about manufacturing specs, precision means getting consistent results when measuring multiple times, whereas accuracy is about hitting the target value set in the design. Take a CNC machine for instance, if it makes ten parts each with exactly the same 0.002 inch difference from what was planned, those parts are definitely precise, but they still miss the mark on accuracy. The aerospace industry often needs really tight tolerances around plus or minus 0.001 inch, which demands not just machines that produce consistently, but also ones that stay very close to the original blueprint requirements throughout production runs.

Common Tolerance Standards (e.g., ±0.001 Inches) and Their Significance

Tolerances define permissible dimensional variations to ensure functional reliability. Key standards include:

| Tolerance Grade | Typical Range (Inches) | Common Applications |

|---|---|---|

| Fine | ±0.0005 – ±0.001 | Medical implants, optics |

| Medium | ±0.001 – ±0.005 | Automotive, consumer devices |

| Coarse | ±0.005+ | Structural components |

ISO 2768-1 governs general tolerances, while tighter specs such as ±0.001” for CNC machining parts are critical in high-performance industries where fit, function, and safety depend on exact dimensions.

Repeatability and Dimensional Consistency in High-Volume Production

Modern CNC systems achieve repeatability through rigid machine structures, thermally stable spindles, and closed-loop feedback. A 2023 study showed multi-axis machines reduce setup errors by 64%, ensuring consistent dimensions across 10,000+ units. Real-time toolpath adjustments compensate for tool wear and material variability, making precision machining scalable for mass production.

Key Machine Components That Enable High Precision in CNC Machining

Spindle Accuracy and Thermal Stability for Consistent Performance

The CNC spindle is central to precision, combining rotational accuracy with thermal management. Modern spindles operate above 20,000 RPM while maintaining micron-level precision, using compensation systems to counteract heat-induced expansion. High-end models feature liquid-cooled housings and vibration-damping bearings, ensuring stable performance over extended production cycles.

Linear Guides, Ball Screws, and Servo Motors in Precise Motion Control

Precision motion relies on hardened linear guides and recirculating ball screws that limit backlash to ≤3 microns. Paired with servo motors offering 0.1-micron positional feedback, these components enable axis movements accurate to ±0.0002 inches. This integration allows complex geometries to be machined within 5-micron tolerance bands consistently.

Machine Rigidity and Vibration Damping to Maintain Tight Tolerances

Monolithic cast iron bases and polymer-concrete frames provide superior damping, achieving 85% higher efficiency than welded steel alternatives. Four-point leveling systems and isolated mounting pads further minimize harmonic distortion—essential when holding sub-0.001" tolerances in sensitive materials like aluminum or titanium.

Advantages of Multi-Axis Machines in Reducing Setup-Induced Errors

5-axis CNC systems eliminate up to 70% of setup-related inaccuracies by enabling complete part machining in a single fixture. Simultaneous contouring across rotary axes reduces cumulative positioning errors, maintaining angular tolerances within ±0.05° even on complex aerospace components.

CAD/CAM Programming and Simulation for Precision CNC Machining Parts

From Digital Design to Accurate Toolpaths Using CAD/CAM Software

Integrated CAD/CAM systems translate complex 3D designs into precise toolpaths. CAD software creates models with micron-level detail, while CAM converts them into optimized G-code. Platforms like Siemens NX CAM automate programming for milling, turning, and multi-axis operations, reducing manual errors by up to 80% in high-tolerance applications.

Programming Complex Geometries with Advanced CAM Strategies

For intricate features or thin-walled parts, CAM employs adaptive strategies:

- 5-axis toolpaths reduce repositioning for angled surfaces

- Trochoidal milling minimizes tool deflection in hard metals

- Rest machining improves material removal efficiency

These algorithms maintain accuracy below ±0.001" (±0.025 mm), even when working with challenging alloys like titanium or Inconel.

Simulation and Error Prediction to Prevent Machining Mistakes

In virtual environments, systems pick up on potential collisions, track how tools wear down over time, and even spot thermal issues long before actual cutting starts happening. According to research from RapidDirect, around 92 percent of those pesky geometry problems in CNC machined parts could actually be avoided if manufacturers run simulations first. When operators get to see exactly what's happening during material removal in real time, they can adjust feed rates and tweak clamping forces accordingly. This makes it much easier to meet those strict ASME Y14.5-2018 requirements for dimensional accuracy that so many shops struggle with these days.

Tooling, Work Holding, and Setup Best Practices for Dimensional Accuracy

Maintaining dimensional accuracy requires careful selection of tooling, secure work holding, and rigorous machine setup—all essential for meeting exact specifications and minimizing waste.

Selecting Precision Tools and Compensating for Wear During Operation

End mills made from carbide with micro grain structures last anywhere from 3 to 5 times longer before dulling compared to regular carbide tools, especially when working with non ferrous metals. When it comes to CNC machining centers, laser tool setters have become pretty common these days. These devices continuously check tool wear and make automatic adjustments to compensate for any changes in cutting depth, cutting down on dimensional errors by around 60 percent according to industry tests. For those dealing with tight tolerances like in aerospace manufacturing, getting the right tool holder makes all the difference. Systems like hydraulic chucks or thermal shrink fit adapters keep run out below 0.0002 inches, something absolutely necessary when producing parts that need to meet strict quality standards.

Effective Work Holding to Prevent Part Deformation and Misalignment

Secure fixturing prevents deflection during machining of thin-walled or high-aspect-ratio parts. Vacuum tables and magnetic chucks distribute clamping force evenly, reducing localized stress by 40–70% compared to mechanical clamps. Modular fixturing with kinematic coupling achieves repeatability within 5 microns across setups, enabling fast changeovers without sacrificing precision.

Calibration and Alignment Procedures for Optimal Machine Setup

Pre-production calibration verifies spindle perpendicularity (≤0.0001" deviation) and axis squareness (≤0.0002" per 12"). Laser interferometers map geometric errors, while ballbar testing identifies circularity issues caused by servo lag or backlash. Facilities following ISO 230-2 alignment standards report 30% lower scrap rates in high-tolerance medical device manufacturing.

Real-Time Monitoring, Quality Control, and Post-Processing Verification

Sensors and feedback systems for real-time adjustments (thermal, wear)

IoT-enabled sensors monitor thermal expansion and tool wear during operation, allowing millisecond-level adjustments to spindle speed and feed rate. These real-time corrections compensate for deviations as small as 0.0002 inches. A 2023 study found that facilities using vibration-damping sensor networks reduced dimensional errors by 47% compared to manual monitoring.

In-process and post-process inspection using CMM and optical scanners

Coordinate Measuring Machines (CMM) verify critical dimensions at key production stages, while blue-light optical scanners generate 3D surface maps with ±2-micron accuracy. This dual verification ensures compliance with ISO 2768 medium tolerances (typically ±0.002 inches) before final processing.

Statistical process control and traceability in mass production

Automated SPC software analyzes data across batches, detecting trends that could affect quality. Manufacturers using real-time statistical controls report 63% fewer tolerance violations in high-volume runs, with full traceability from raw material to finished component.

Deburring, polishing, and secondary operations to achieve final accuracy

Post-machining treatments remove micro-imperfections that impact fit and performance. Automated abrasive finishing achieves surface roughness (Ra) below 8 µin, while robotic polishing maintains ±0.0005" dimensional stability—critical for aerospace and medical applications requiring flawless surface integrity.

FAQs

What is the difference between precision and accuracy in CNC machining?

Precision refers to how consistently a process can produce the same result, while accuracy is about how close those results are to a desired target or specification.

Why are tight tolerances essential in CNC machining?

Tight tolerances are crucial because they ensure that parts fit, function, and perform reliably in demanding applications, such as aerospace and medical devices, where exact dimensions are necessary for safe and effective operation.

How does CAD/CAM software contribute to precision in CNC machining?

Cad/CAM software translates detailed 3D designs into precise toolpaths for machining, reducing manual errors and optimizing operations to maintain high levels of accuracy.

What role does real-time monitoring play in maintaining CNC machining accuracy?

Real-time monitoring using IoT-enabled sensors allows for immediate adjustments during machining, compensating for thermal expansion and tool wear, which helps maintain dimensional accuracy.

How do 5-axis machines improve CNC machining processes?

5-axis CNC machines allow for complete part machining in a single setup, reducing error accumulation from multiple setups and maintaining precise angular tolerances across complex surfaces.

Table of Contents

- Understanding Precision, Accuracy, and Tolerances in CNC Machining Parts

- Key Machine Components That Enable High Precision in CNC Machining

- CAD/CAM Programming and Simulation for Precision CNC Machining Parts

- Tooling, Work Holding, and Setup Best Practices for Dimensional Accuracy

- Real-Time Monitoring, Quality Control, and Post-Processing Verification

-

FAQs

- What is the difference between precision and accuracy in CNC machining?

- Why are tight tolerances essential in CNC machining?

- How does CAD/CAM software contribute to precision in CNC machining?

- What role does real-time monitoring play in maintaining CNC machining accuracy?

- How do 5-axis machines improve CNC machining processes?