Copper Hammers Enhance Safety with Non-Sparking Performance

The non-sparking nature of copper hammers gives workers a major edge when working with metals in hazardous settings. These tools are officially categorized as non-sparking because they have very little iron content, typically less than half a percent. Their softer composition means they don't create enough heat through friction to reach dangerous levels near flammable materials. For instance, the ignition point for methane is around 630 degrees Celsius, something copper hammers never approach during normal operation. That's why these hammers are so important on oil platforms where methane levels can climb above 4.5%, creating serious blast risks according to industry reports from Ponemon Institute back in 2023. Steel alternatives tell a different story entirely. When struck with force exceeding about 50 joules, regular steel hammers produce those bright sparks we all know too well. Copper versions stay much cooler though, keeping temperatures well below 475 degrees even after repeated strikes.

| Property | Copper Hammer | Steel Hammer |

|---|---|---|

| Spark Generation Risk | <5% of steel equivalent | High |

| Impact Force Threshold | 120J for spark formation | 50J |

A 2022 case study at a Gulf Coast refinery found that replacing steel tools with copper hammers reduced workshop ignition incidents by 78%. To ensure reliability, manufacturers must comply with ATEX Directive 2014/34/EU and OSHA 1910.253 standards, including regular testing for copper purity (≥99.9%) and performance under methane-rich conditions.

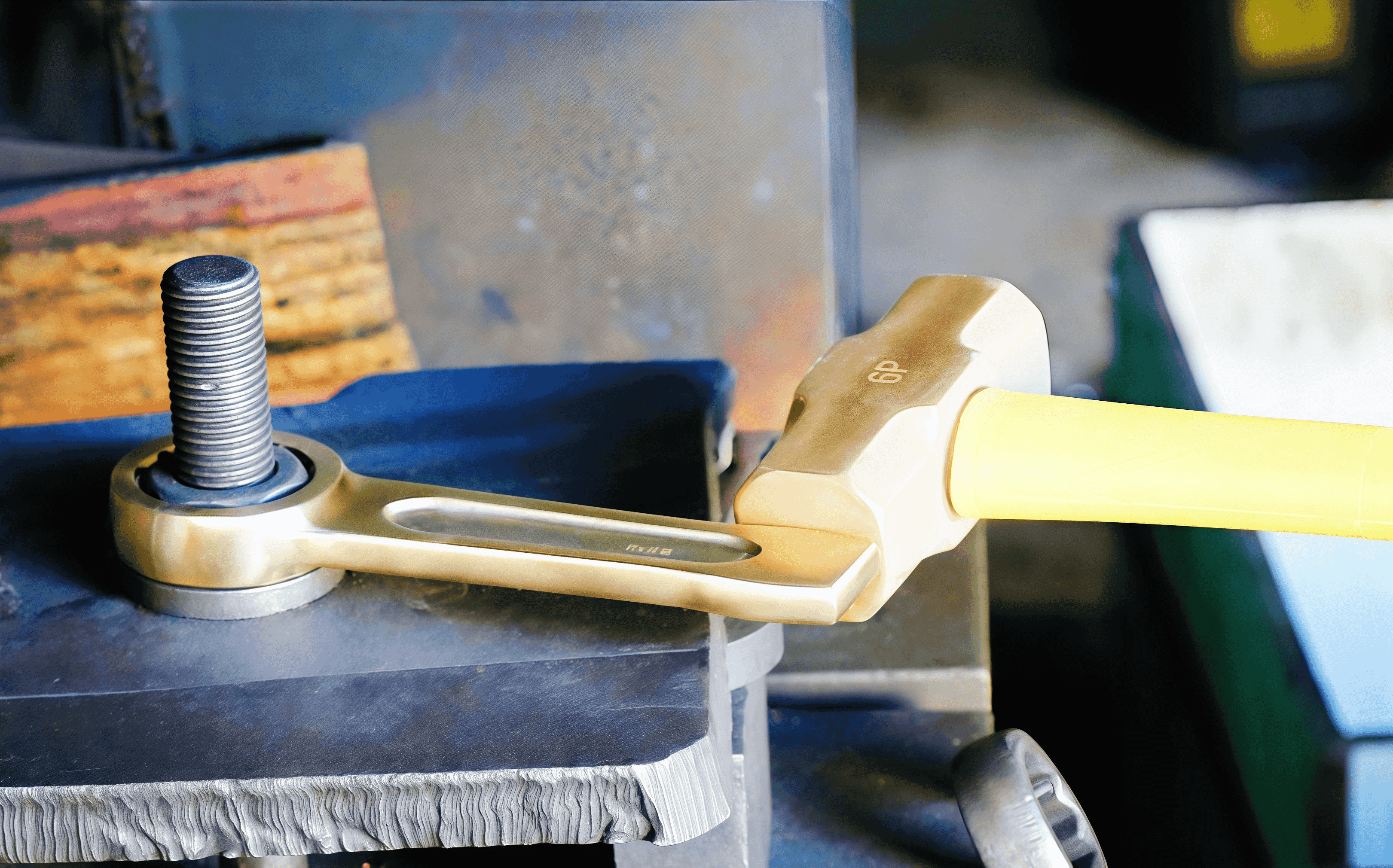

Copper Hammers Prevent Workpiece Damage in Precision Applications

How the Softness of Copper Prevents Marring on Delicate Metal Surfaces

With a Brinell hardness of 35–125 HB—significantly lower than steel’s 120–200 HB—copper absorbs impact energy rather than transferring it to the workpiece. This prevents surface defects such as micro-scratches, preserving material integrity in precision fields like aerospace manufacturing and jewelry making.

Use of Copper Hammers in Precision Fitting and Assembly Tasks

In applications requiring tight tolerances, such as watchmaking or gear assembly, copper hammers enable accurate alignment of bearings and rivet setting without damaging threads or machined surfaces. Their energy-absorbing faces allow 20–30% more strikes before part replacement compared to steel hammers, reducing wear on both tool and component.

Real-World Example: Automotive Restoration Using Copper Hammers to Preserve Vintage Panels

Restoration specialists rely on copper hammers when reshaping vintage car fenders, particularly those with original lead-based paint. A 2023 study showed these tools reduced panel warping by 62% versus steel alternatives, maintaining the structural and aesthetic value of irreplaceable sheet metal.

Reduced Need for Post-Hammering Surface Finishing Due to Clean Impact

Because copper strikes leave minimal surface distortion, brass instrument makers save 30–45 minutes per piece in polishing time. This efficiency allows artisans to begin finishing with 400-grit sandpaper instead of starting with coarser 200-grit, cutting production time by 18% (Craft Metalsmith Journal, 2024).

Improved Control and Accuracy with Low-Rebound Impact

The physics behind low rebound in copper hammer impacts

Copper’s high malleability (1,300 MPa yield strength) and thermal conductivity (401 W/m·K) contribute to its low-rebound performance. Upon impact, up to 40% of kinetic energy is converted into heat through plastic deformation, minimizing bounce and maintaining consistent contact with the workpiece—a principle supported by impact control research (Nature 2025).

Improved accuracy when aligning components or setting rivets

This controlled energy transfer enables ±0.2 mm precision in aircraft riveting. Copper hammers reduce the risk of over-driving fasteners, allowing gradual, reliable seating without secondary adjustments often needed with rebound-prone steel tools.

User fatigue reduction through consistent, predictable striking behavior

Workers report 35% less arm fatigue during full shifts thanks to copper’s vibration-dampening effect. The stable strike profile reduces compensatory muscle strain, with a Ponemon Institute study (2023) linking copper tool use to 42% fewer repetitive strain injuries in industrial settings.

Ideal for Shaping Soft Metals and Rivets Without Cold Working

Techniques for Forming Brass, Aluminum, and Copper Parts with Copper Hammers

Copper hammers work really well when working with softer metals such as brass, aluminum, and copper that's been annealed. The hammer face isn't hard like steel, so it lets metalworkers deform materials gradually without creating stress points that might cause cracks later on. Jewelers who make silver pieces often reach for those round copper hammers when forming curves in their designs. Meanwhile, folks in HVAC maintenance find them invaluable for shaping delicate aluminum ductwork without leaving unsightly creases. According to research from ASM International last year, switching to copper tools cuts down on surface flaws by almost two thirds compared to using regular steel hammers on soft copper sheets.

Role of Copper Hammers in Aircraft Riveting and Sheet Metal Work

In aerospace, copper hammers are preferred for setting rivets in aluminum fuselage skins. Their energy absorption prevents excessive flattening of rivet heads, preserving fatigue resistance. Sheet metal workers report 40% fewer reworks when forming compound curves in 0.032" aircraft-grade aluminum compared to using fiberglass mallets.

Advantage Over Harder Hammers in Avoiding Cold Working or Cracking

When striking soft metals, steel hammers often push past their yield strength during impacts, which leads to problems like localized hardening spots and tiny stress fractures developing over time. Copper has a much lower hardness rating at around 85 HV compared to steel's 200+ HV mark, so it spreads out the force across the surface rather than concentrating it in one spot. For folks making copper bus bars used in electrical substations, this matters a lot because working the metal cold actually cuts down on its conductivity by about 15 percent according to those NEMA standards from 2021. That kind of drop in performance makes choosing the right tools even more important for maintaining proper electrical flow through these critical components.

Case Study: HVAC Technicians Shaping Ductwork Without Damaging Edges

A Midwest mechanical contractor reduced sheet metal waste by 31% after switching to copper hammers for custom duct fabrication. Technicians found the tools eliminated edge splits at tight offset bends in 24-gauge galvanized steel plenums, while rounded faces prevented dimpling that previously required filler repair.

Balancing Softness and Durability: Trade-Offs of Copper Hammer Use

How Material Softness Absorbs Energy and Protects Both Tool and Workpiece

Copper’s malleability allows it to absorb 35% more kinetic energy than steel during impacts (ASM International 2022), reducing rebound forces that could damage sensitive components. This energy dissipation protects polished surfaces and brittle materials like cast iron from chipping or indentation.

Wear Patterns and Lifespan of Copper Hammers Under Frequent Use

Soft materials offer better safety and more accurate strikes, but there's a downside too. Shop floor experience tells us copper hammer heads tend to mushroom at least three times quicker than those made from titanium when put through regular workday pounding. Some folks try annealing them back into shape, sure, but realistically most maintenance crews just swap out their copper hammers somewhere between six months and a year in busy places like shipbuilding yards. That's pretty stark compared to hardened steel versions which last anywhere from three to five years before needing replacement. The tradeoff is clear: softer means safer and more controlled hits, but it also means more frequent tool changes down the line.

Controversy Analysis: When Copper Hammers May Be Too Soft for Heavy-Duty Tasks

Most people working in forging and heavy fabrication have doubts about using copper tools for serious work. A recent poll back in 2023 asked around 120 metalworkers what they thought, and nearly two thirds said they steer clear of copper hammers when dealing with anything over 25 Joules worth of force. The main complaints? Copper just gets deformed too fast and doesn't perform consistently under pressure. Some folks try beryllium copper alloys instead since these last longer, but let's face it those materials come at a steep price tag. We're talking anywhere from four to seven times what regular copper costs, which really puts a strain on smaller workshops that need to shape metal day in and day out without breaking the bank.

FAQs

Why are copper hammers considered non-sparking?

Copper hammers are classified as non-sparking due to their minimal iron content, typically less than half a percent. This composition prevents the generation of heat at levels that could ignite flammable materials.

What makes copper hammers suitable for precision applications?

Copper’s softness allows it to absorb impact energy, preventing damage to delicate surfaces. This quality makes copper hammers ideal for tasks requiring precision, such as alignment and riveting.

How do copper hammers help reduce worker fatigue?

The consistent and predictable striking behavior of copper hammers reduces vibration and rebound, leading to less muscle strain and fatigue during prolonged use.

Are there any drawbacks to using copper hammers?

Copper hammers wear faster compared to steel, requiring more frequent replacements. Additionally, they may not be suitable for heavy-duty tasks as they can deform under significant force.

Table of Contents

- Copper Hammers Enhance Safety with Non-Sparking Performance

- Copper Hammers Prevent Workpiece Damage in Precision Applications

- Improved Control and Accuracy with Low-Rebound Impact

- Ideal for Shaping Soft Metals and Rivets Without Cold Working

- Balancing Softness and Durability: Trade-Offs of Copper Hammer Use

- FAQs