What Are Non Sparking Tools and How Do They Prevent Hazards?

Understanding Non Sparking Tools and Their Role in Spark Prevention

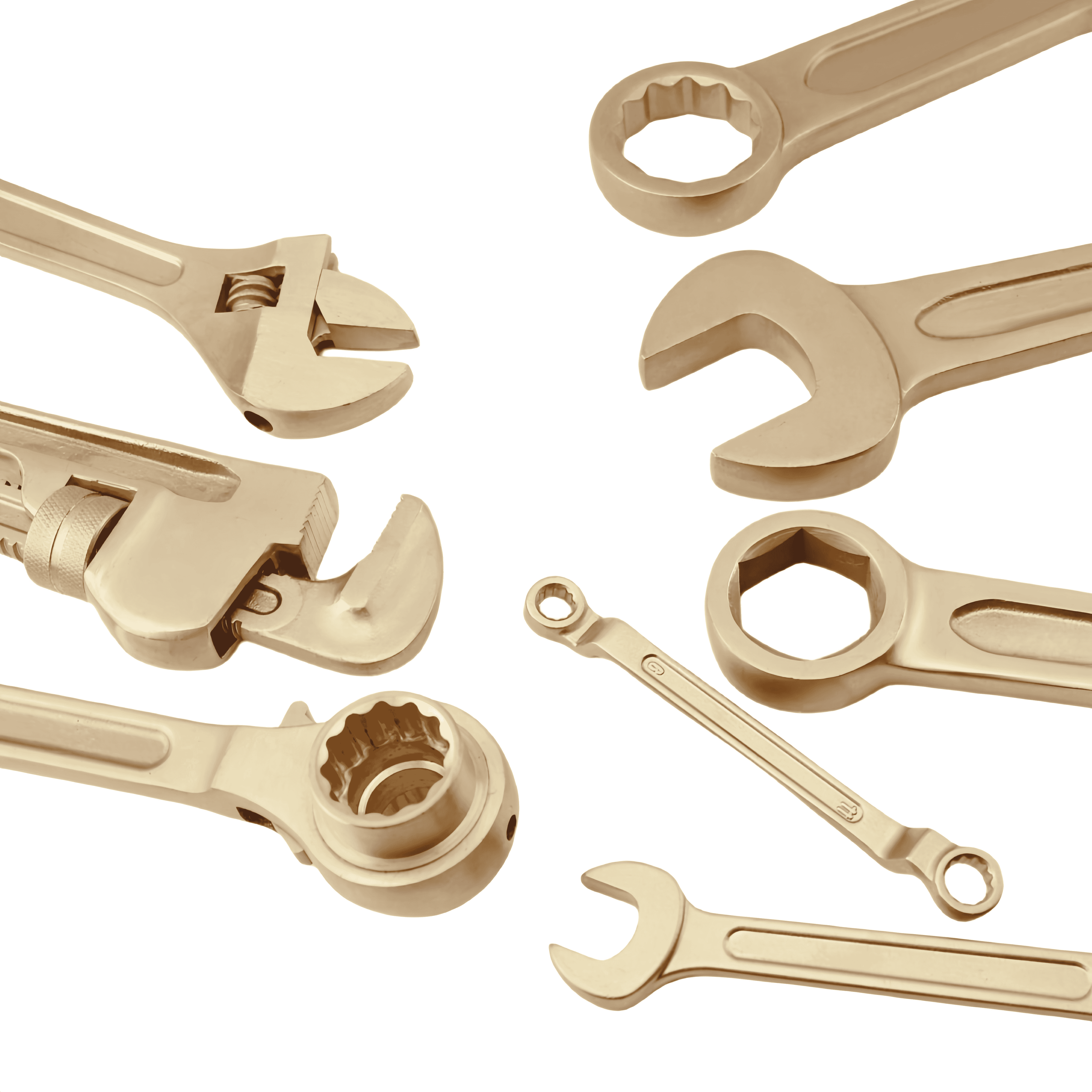

Non sparking tools help stop accidents in places where things can catch fire easily because they're made from materials that don't create sparks. Regular steel tools might generate hot sparks when rubbed against something or hit hard, but these special tools come from different metals like brass or copper alloys. These materials take in the energy instead of letting it fly out as dangerous sparks. Workers need them especially bad in places like oil rigs, chemical plants, and biogas facilities. A tiny spark there isn't just annoying it could start a major disaster. That's why safety regulations often require their use in hazardous areas where explosive gases might be present.

Material Composition: Copper-Beryllium, Aluminum-Bronze, and Other Non Sparking Alloys

Most of these specialized tools come made from copper beryllium alloy (CuBe) or aluminum bronze (Al-Bronze). Both materials stand out because they last longer and won't create sparks when struck against other metals. What makes these alloys so useful? They conduct heat poorly and resist sticking together even during heavy impacts, so they bend instead of creating friction heat. Take CuBe specifically it can handle really intense pressure around 35 thousand pounds per square inch before breaking down. That kind of strength means these tools work great in tough industrial settings where valves need adjusting inside oil refineries and similar environments.

The Science Behind Spark Suppression in Conductive Materials

Non-sparking alloys work to stop fires because they cut down on both the heat from friction and the actual spark energy itself. The way these materials are built at the atomic level means that when something hits them, the impact gets absorbed through plastic deformation instead of creating those dangerous hot particles we usually see. Tests show surface temps can drop around 80 percent lower than what happens with regular carbon steel. Another key feature is how well they conduct electricity. This helps spread out any concentrated energy points so sparks just don't reach that critical 0.025 mJ level required to light up flammable stuff like methane or hydrogen gas. For workplaces dealing with explosive environments, this kind of material meets all the important safety requirements set by organizations such as OSHA and NFPA, making it a smart choice for keeping operations running safely.

Dangers of Using Standard Tools in Flammable and Explosive Settings

How Regular Steel Tools Generate Dangerous Sparks

Regular steel tools are made mostly of iron, which is a type of ferrous metal known for sparking when it hits or rubs against tough surfaces. What makes this dangerous? Well those little sparks can get really hot, sometimes reaching temperatures above 1,370 degrees Fahrenheit. That kind of heat is plenty enough to set off flammable gases like methane or hydrogen floating around in the air. How does all this happen? The process starts with something called triboelectric charging. Basically, when these tools make contact with other materials, they generate mechanical energy that charges up tiny particles in the atmosphere. This charge builds until it creates those fiery sparks we're talking about.

Case Study: Ignition Incident in a Petrochemical Facility Due to Metal-on-Metal Contact

A major explosion hit a refinery along the Gulf Coast back in 2022 after maintenance crews were working on fuel lines. They had grabbed a steel wrench for the job but accidentally struck a metal pipe bracket nearby. The sparks from this simple mistake set off flammable vapors that had been leaking, leading to massive destruction worth around $18 million dollars and forcing the facility offline for nearly four months straight. What makes this situation particularly concerning is how something so ordinary turned into such a catastrophe simply because workers didn't have the right equipment for what they were doing according to recent findings published by Industrial Safety Journal.

Common Scenarios Where Sparks Trigger Fires or Explosions

- Grinding or pounding metal: Sparks near fuel tanks or solvent storage areas

- Dropping tools: Impact on concrete in paint spray booths containing flammable vapors

- Static discharge: Steel tools contacting charged equipment in grain silos with combustible dust

Cost vs. Safety Debate: Why Some Still Risk Using Standard Tools

A lot of facilities still stick with regular tools even though everyone knows the dangers involved. About 34 percent of those at high risk for accidents do this just to save money upfront since non-sparking options cost two to three times more according to NFPA data from 2023. What these places don't consider is what happens down the road. When fires break out in chemical plants, insurance companies typically pay around seven hundred forty thousand dollars per claim. So investing in safer tools actually makes financial sense in the long run. The numbers back it up too the return on investment is roughly nine to one when facilities upgrade their equipment properly.

Key Applications of Non Sparking Tools Across High-Risk Industries

Non sparking tools are indispensable in industries where flammable substances and explosive atmospheres create constant ignition risks. Their specialized material composition prevents catastrophic spark generation during metal-on-metal contact, making them mandatory for critical operations.

Oil and Gas Sector: Maintenance in Refineries and Offshore Platforms

Valve adjustments and equipment repairs on offshore platforms and in refineries require tools that won’t ignite methane or hydrogen. Non sparking wrenches, hammers, and drills eliminate ignition risks during maintenance in confined spaces saturated with combustible gases.

Chemical Manufacturing: Safe Handling of Volatile Substances

When transferring solvents, polymers, or reactive chemicals, workers use non sparking scoops, scrapers, and drums to prevent static discharges. These tools ensure safe handling in environments where vapor concentrations approach or exceed lower explosive limits (LELs).

Biogas Plants: Mitigating Explosion Risks in Anaerobic Digesters

Anaerobic digesters produce methane-rich gas, creating highly explosive conditions. During sludge removal, non sparking shovels and pry bars prevent ignition in enclosed spaces where methane levels range between 4.4% and 22% in air.

Pharmaceutical and Paint Industries: Preventing Dust and Vapor Ignition

In powder blending stations and paint spray booths, non sparking spatulas, mixers, and containers help prevent ignition of combustible dust clouds or alcohol-based vapors, ensuring compliance with explosion safety protocols.

Safety Advantages and Proven Impact of Non Sparking Tool Implementation

Reducing Ignition Sources in Classified Hazard Zones

In Class I Div 2 environments and Zones 1/2 where flammable gases might be present, non sparking tools take care of a major fire hazard that could otherwise be avoided. When workshops swap out regular steel implements for materials such as copper beryllium alloy, they cut down on sparks flying around during routine repairs or when dealing with emergencies. The switch makes good sense from both safety and legal standpoints too. Most companies find that following this approach fits right into their overall safety protocols and helps them stay within OSHA guidelines regarding workplace hazards. After all, nobody wants an unexpected spark turning into something much worse just because someone used the wrong tool for the job.

Data Insight: Reduction in Fire Incidents After Adopting Non Sparking Tools

A 2023 analysis of 14 chemical plants showed a 68% decrease in spark-related near-misses after switching to non sparking tools. NFPA research confirms that 72% of tool-caused industrial fires result from metal-on-metal contact. Facilities implementing these tools report fewer shutdowns and reduced insurance costs—one oil refinery saved $2.1 million annually in incident-related expenses.

Integration with Safety Control Hierarchies and Hazard Management Systems

Top companies don't just grab non-sparking tools and call it a day when building their safety protocols. They actually combine these specialized instruments with other protective measures like gas detection systems, proper grounding equipment, and specially treated floors that prevent static buildup. Take spark-proof wrenches for example. When paired with properly bonded workstations, they offer multiple lines of defense against accidents while working with flammable materials. Most industrial facilities follow this multi-layered strategy not only because it meets OSHA standard 1910.307 requirements for dangerous environments but also because experienced managers know firsthand how these combinations reduce workplace incidents across different manufacturing settings.

Regulatory Standards and Compliance for Non Sparking Tools (OSHA, ANSI, NFPA)

OSHA Requirements for Tool Use in Hazardous Locations

OSHA regulation 1910.242 sets rules for using non-sparking tools when working around flammable materials like gases, vapors, or combustible dust. Workplaces need to supply these special tools so they don't create sparks during tasks such as fixing pipes at oil refineries. Regular checking is part of the deal too. Most places do weekly inspections to make sure everything stays safe in areas where accidents could happen fast, especially around fuel storage tanks and similar locations. These checks help maintain tool condition and prevent dangerous situations from developing over time.

ANSI and NFPA Guidelines for Non Sparking Equipment in Flammable Atmospheres

The ANSI B107 committee handles standards for non-sparking tools, looking at things like how strong materials are under tension and whether certain alloys such as copper beryllium will actually resist sparking when struck against other surfaces. When it comes to dangerous environments, the NFPA steps in with their codes. Their NFPA 70 document, better known as the National Electrical Code, plus NFPA 497 deal specifically with areas where flammable gases or vapors might be present. These documents basically map out different risk levels and tell workers what kind of gear they need to stay safe. Even though these NFPA rules aren't mandatory by themselves, most companies end up following them anyway because OSHA tends to pick them up and turn them into actual requirements during inspections.

When Non Sparking Tools Are Legally Mandatory by Industry

Regulatory requirements make non sparking tools compulsory in several sectors:

- Petrochemical plants: Required during tank cleaning and valve work under OSHA’s Process Safety Management (29 CFR 1910.119).

- Grain processing: Enforced under OSHA’s Combustible Dust National Emphasis Program.

-

Aerospace manufacturing: Mandated by Defense Logistics Agency (DLA) specifications for fuel system servicing.

An industrial safety review in 2023 found that 89% of noncompliant facilities in these industries faced penalties.

DOT Regulations for Transport and Maintenance Involving Explosive Materials

According to the Department of Transportation regulations found in 49 CFR Part 177, workers dealing with vehicles carrying explosives like dynamite or ammonium nitrate need to stick to non-sparking tools. That means no regular metal wrenches or hammers around those hazardous loads. The rulebook specifically calls for spark-resistant versions of common workshop tools when doing maintenance checks or making repairs on transport equipment. And let's be clear about what happens if someone ignores this safety protocol. The fine amounts have gone up quite a bit since last year, now sitting at around $83k per violation according to the latest 2024 enforcement schedule from the DOT. For companies that keep breaking these rules, there's even more at stake beyond just money penalties. Repeat violations could actually lead to having their operating licenses pulled entirely, which would shut down entire operations until everything gets sorted out properly.

Frequently Asked Questions

What are non sparking tools made of?

Non sparking tools are typically made from copper-beryllium alloy or aluminum bronze. These materials are used because they do not create sparks when struck against other metals.

Why is it important to use non sparking tools in hazardous environments?

In environments where flammable gases or vapors are present, even a small spark can ignite a fire or explosion. Non sparking tools prevent the generation of these sparks, reducing the risk of accidents.

Are non sparking tools required by law?

Yes, in certain high-risk industries such as petrochemical plants, grain processing, and aerospace manufacturing, the use of non sparking tools is mandated by OSHA and other regulatory bodies to prevent workplace accidents.

How do non sparking tools work?

Non sparking tools reduce the risk of sparking by absorbing impact energy through plastic deformation. This minimizes both the heat from friction and actual spark energy, making it harder for ignition to occur in flammable environments.

Table of Contents

- What Are Non Sparking Tools and How Do They Prevent Hazards?

- Dangers of Using Standard Tools in Flammable and Explosive Settings

- Key Applications of Non Sparking Tools Across High-Risk Industries

- Safety Advantages and Proven Impact of Non Sparking Tool Implementation

- Regulatory Standards and Compliance for Non Sparking Tools (OSHA, ANSI, NFPA)

- Frequently Asked Questions