High-Precision Laser Cutting Technology: Precision Cutting Solutions Empowering High-End Manufacturing

In the wave of global high-end manufacturing upgrading, laser cutting has become a key process in the metal processing field, thanks to its core advantages of ultimate precision, high efficiency and flexibility. As a leading enterprise deeply rooted in the hardware, electromechanical and metal processing industries for over 10 years, Deeplink has leveraged its integrated whole-industry-chain capabilities to develop laser cutting technology into the core competitiveness of customized metal processing, providing stable and reliable cutting solutions for global high-end manufacturing.

Laser Cutting Technology: Perfect Integration of Precision and Efficiency

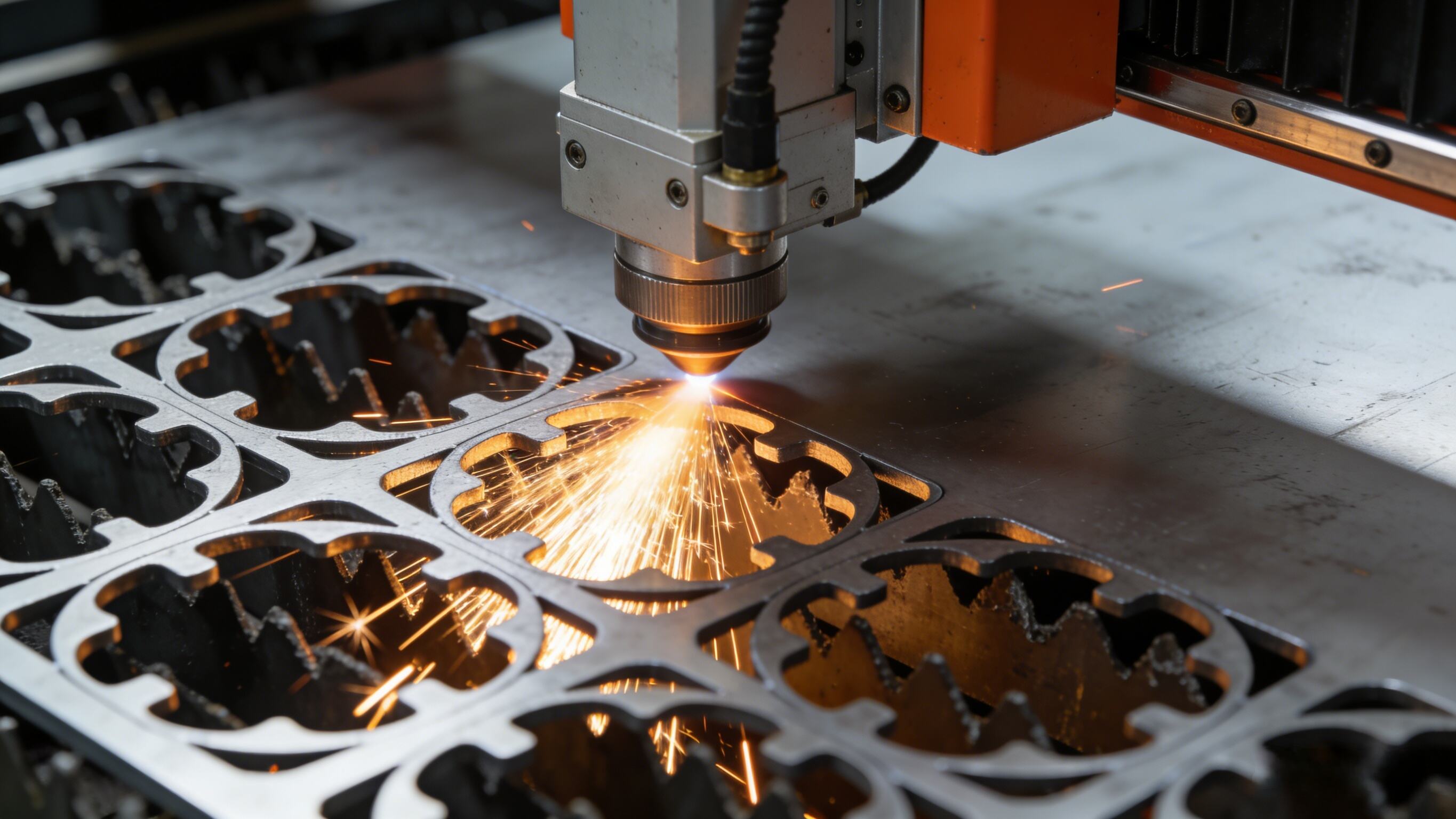

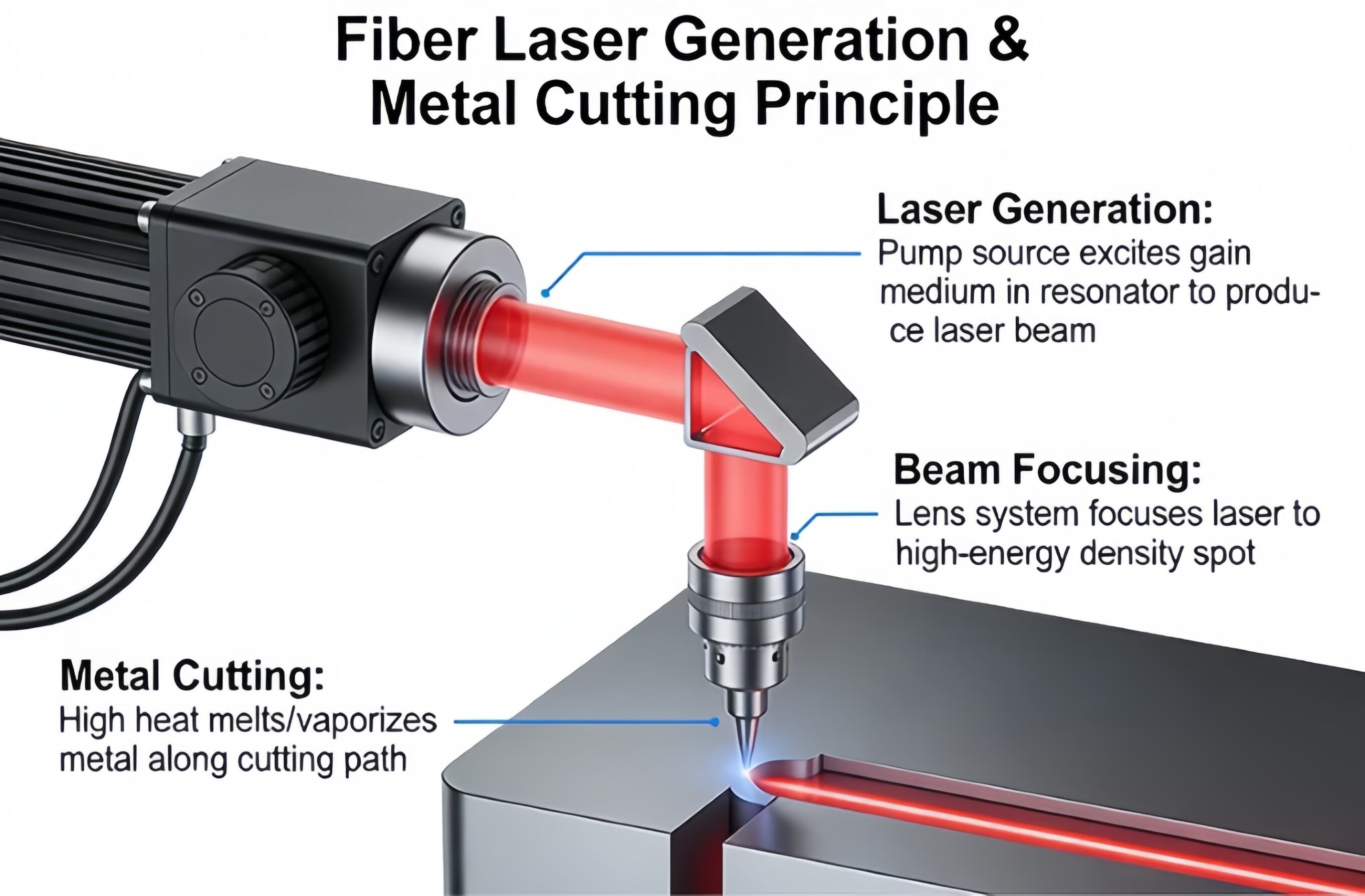

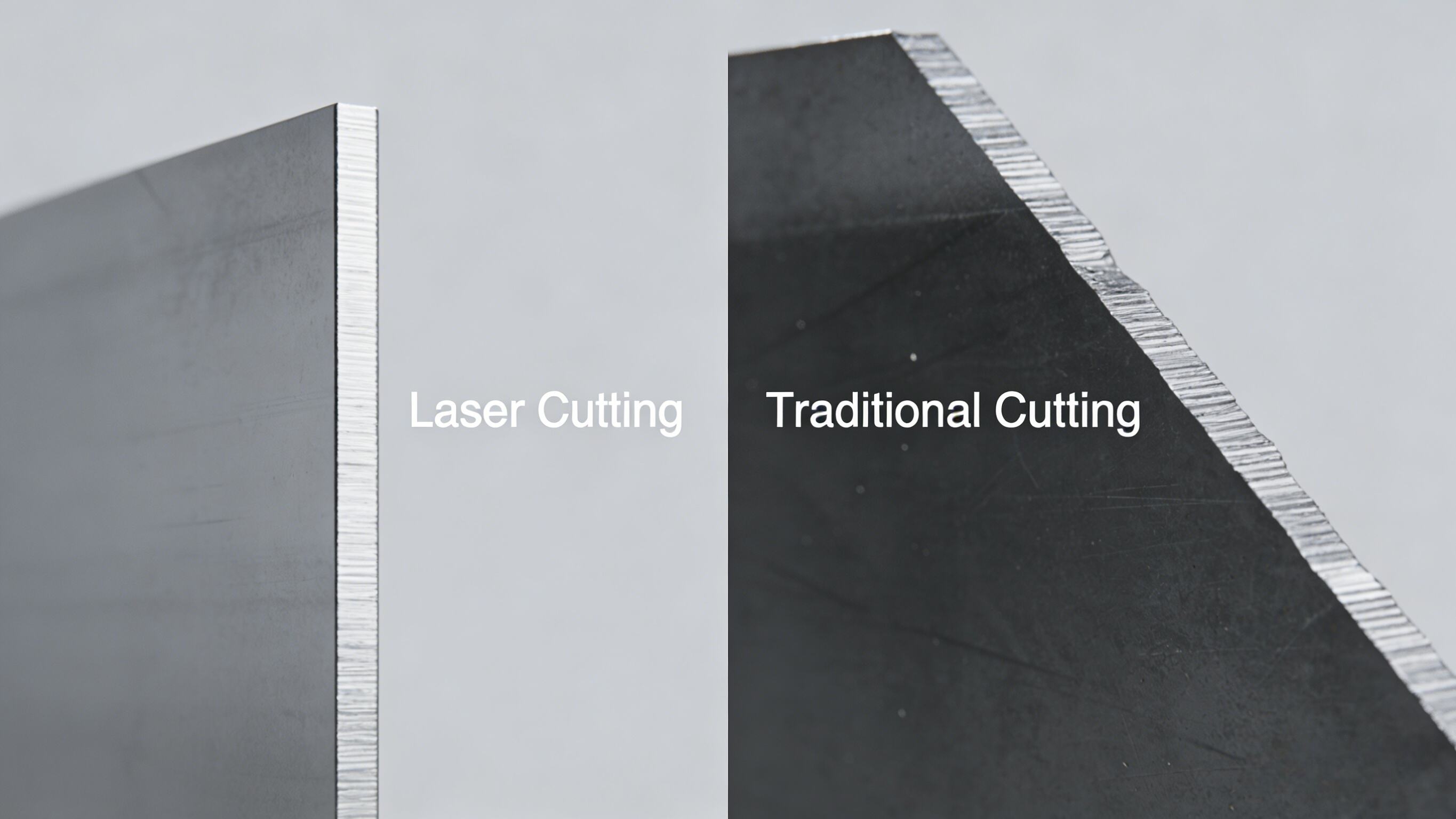

Laser cutting is an advanced processing technology that uses a high-energy-density laser beam to precisely melt, vaporize or strip metal materials. Compared with traditional cutting methods, its core advantages are particularly prominent:

Ultimate Precision: Controlled by a CNC numerical control system, the cutting tolerance can be maintained at the micron level, perfectly meeting the processing needs of complex parts without subsequent tedious grinding.

High Efficiency and Flexibility: Supports cutting of various metal materials such as stainless steel, aluminum, copper,brass and carbon steel, enabling rapid response from single-piece prototypes to mass production and significantly shortening the production cycle.

High-Quality Cuts: The cutting surface is smooth and burr-free with a minimal heat-affected zone, maximizing the retention of the material's original properties and reducing resource waste.

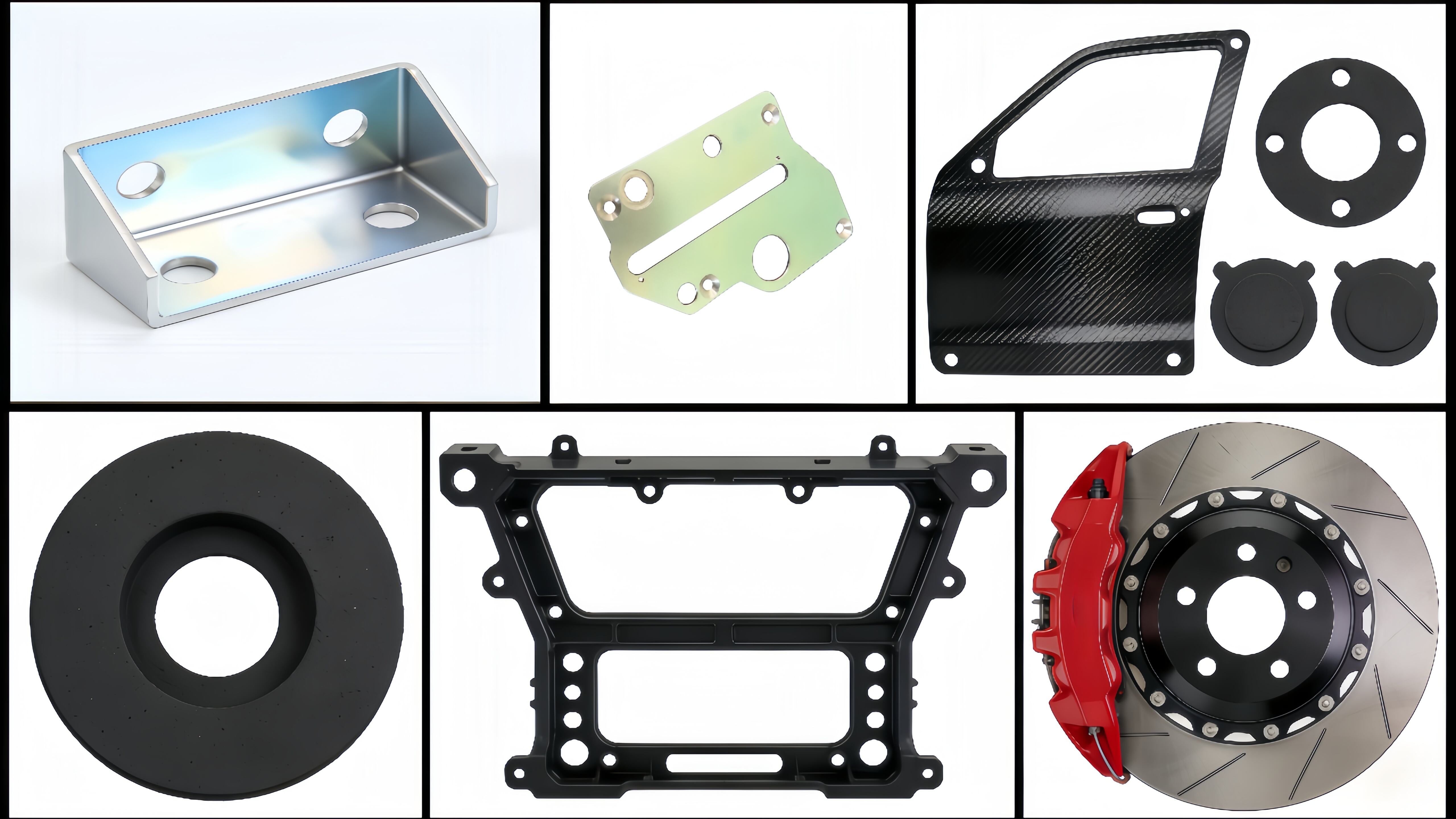

Custom Adaptability: Easily achieves cutting of complex shapes and special structures, perfectly matching the personalized needs of multiple industries including automotive, electronics, new energy and petrochemicals.

Deeplink Laser Cutting Services: Core Advantages Creating Industry Benchmarks

1. Technical Strength: Dual Guarantee of Automation and Precision

We are equipped with 6 automated production lines with an automation level of up to 80%, coupled with internationally advanced CNC laser cutting machines and DFM (Design for Manufacturing) analysis systems to avoid processing risks from the early design stage. Combined with more than 39 quality inspection processes, we ensure every cut product meets strict precision standards, enabling stable mass production even for metal components with complex structures.

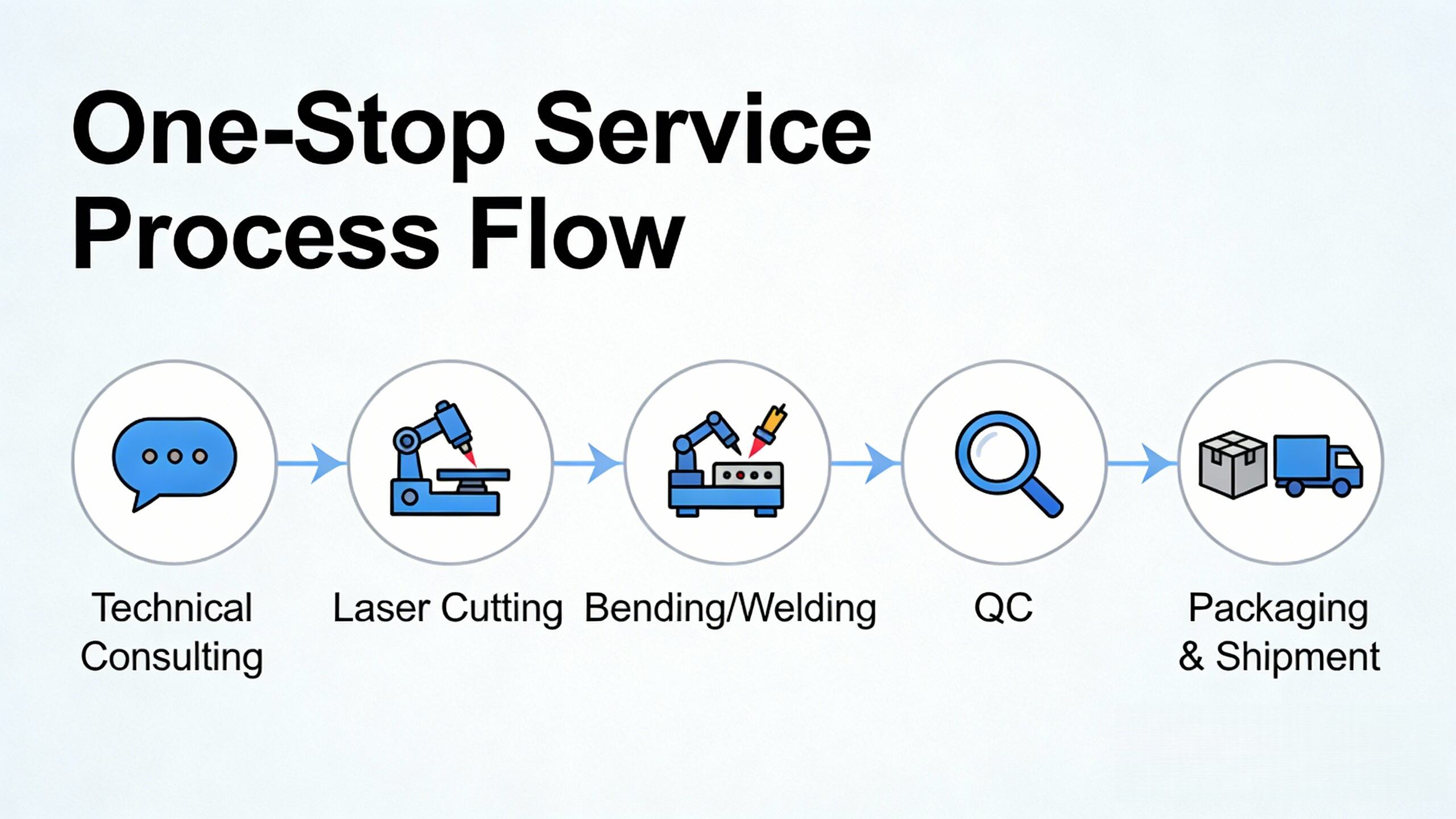

2. Whole-Chain Service: One-Stop Peace of Mind from Design to Delivery

As a supply enterprise with a complete industrial chain, we provide a full-process service including "Technical Consulting - Drawing Design - Prototype Testing - Laser Cutting - Welding & Assembly - Packaging & Shipping". There is no need to cooperate with multiple suppliers; customers only need to put forward their requirements, and we can control the entire process from program optimization to finished product delivery. With our "fast delivery" commitment, we greatly improve the efficiency of customers' project progress.

3. Quality Certification: Globally Recognized Reliable Guarantee

The company has obtained multiple international authoritative certifications such as SGS, RoHS, REACH, ISO9001, ISO14001 and ISO45001. Our laser cutting products not only comply with environmental and safety standards but also meet the quality requirements of global high-end manufacturing. For years, we have provided laser cutting supporting services for many enterprises, and our quality reputation has stood the test of the market.

4. Customization Capability: Flexible OEM/ODM Adaptation

Targeting the personalized needs of different industries and scenarios, we offer professional OEM/ODM customization services. Whether it is precision structural parts for new energy vehicles or micro metal components for the electronics industry, we can tailor laser cutting solutions according to customers' drawings and performance requirements, achieving seamless connection from prototype to mass production.

From auto parts to new energy equipment, from non sparking safety tools for the chemical industry to electronic precision parts, Deeplink's laser cutting technology is deeply empowering various fields of global high-end manufacturing. If you need high-precision and cost-effective metal laser cutting solutions, welcome to contact us for free DFM analysis and customized quotes. Let us help your projects land successfully with exquisite technology and whole-chain services!