In flammable and explosive high-risk scenarios such as petrochemicals, hazardous chemical storage and transportation, and metallurgical processing, tiny sparks generated during tool use are likely to become the "trigger" for explosive accidents. With comprehensive safety performance and a variety of material and style options, DeepLink Non-sparking/Explosion-proof Safety Shovel has become an essential tool in high-risk industries, ensuring the safe operation of frontline personnel.

DeepLink Non-sparking Shovel boasts four core safety features to eliminate operational risks from the source:

Based on the safety features of no spark safety tools, DeepLink Anti-spark safety Shovel can meet the operational needs of different high-risk industries, with one tool suitable for multiple scenarios:

1.Petrochemical Industry: Suitable for tank farm cleaning, crude oil residue shoveling and transportation, and material transfer in refining workshops. No spark spade can withstand oily environments and will not generate sparks to ignite oil and gas.

2.Gas Industry: Ideal for debris cleaning around gas storage tanks, shoveling in underground mine areas with high concentrations of combustible gases, and material organization at gas pipeline construction sites. Explosion proof shovel ensures safety through its anti-static and non-sparking properties.

3.Coal Mining Industry: Adaptable for underground coal shoveling, roadway debris cleaning, and can withstand humid and gas-rich environments. The non-sparking and anti-static design prevents gas explosions.

4.Metallurgical Industry: Applicable for the production and transportation of combustible metal powders such as aluminum powder and magnesium powder. The magnetism-proof and non-sparking properties of safety spade prevent metal dust from causing explosions.

5.Power Industry: Suitable for debris cleaning in substations and fuel engine rooms, fuel shoveling and loading, as well as material organization at power equipment maintenance sites.Aluminum Bronze /Beryllium copper shovel avoids sparks and static electricity from affecting the safety of power equipment.

6.Food Industry: Can be used for shoveling and loading combustible dust raw materials such as flour and starch, and workshop cleaning. Copper alloy tools has no impurity shedding and is anti-static, ensuring food hygiene while preventing dust explosions.

7.Plastic and Chemical Fiber Industry: Suitable for shoveling and loading plastic particles and chemical fiber raw materials, and workshop cleaning. The anti-static property of non sparking safety tools prevents dust accumulation from causing explosions, adapting to high-temperature and dry environments.

8.Civil Explosives Production and Transportation Industry: Applicable for shoveling and loading raw materials of fireworks, firecrackers, and blasting equipment, as well as emergency organization during transportation and storage. Bronze tools is non-sparking and impact-resistant, complying with industry safety standards.

9.Pharmaceutical Industry: Suitable for shoveling and loading flammable and explosive pharmaceutical granules and raw materials. It is carbon-free and has no impurity shedding, ensuring no contamination of medicines and no sparks to cause dangers.

10.Marine Industry: Can be used for cleaning ship fuel tanks, organizing flammable and explosive materials on decks, and shoveling debris at maintenance sites. It is corrosion-resistant and moisture-resistant, adapting to marine environments. Typical non-sparking/explosion-proof shovel models include IMPA: 615958 SHOVEL ROUND NON-SPARK, SPECIAL ALUMINUM BRONZE 225X970MM, IMPA: 615959 SHOVEL ROUND NON-SPARK, BERYLLIUM ALLOY 224X970MM.

11.Military and Aerospace Industry: Adaptable for high-risk material handling and material shoveling at equipment maintenance sites. Bronze spade is non-sparking, magnetism-proof, and corrosion-resistant, meeting stringent safety requirements.

12.Magnetic Material Production Industry: Suitable for shoveling and loading magnetic material raw materials and workshop cleaning. The magnetism-proof property of Brass shovel/Beryllium copper spade does not interfere with magnetic material production, and the non-sparking design avoids potential safety risks.

III. Diverse Material Options and Flexible Style Configurations: Meeting Different Operational Needs

DeepLink Non-sparking safety Shovel offers three core explosion-proof material options, accurately matching different hazard levels, operational intensities, and budget requirements. All three have passed strict anti-spark tests, ensuring reliable safety performance:

1.Aluminum Bronze: Explosion-proof grade ExIIB, hardness 20HRC~30HRC

2.Beryllium Copper: Explosion-proof grade ExIIC, hardness 30HRC~40HRC

3.Brass: Non-sparking and anti-static, cost-effective,low price

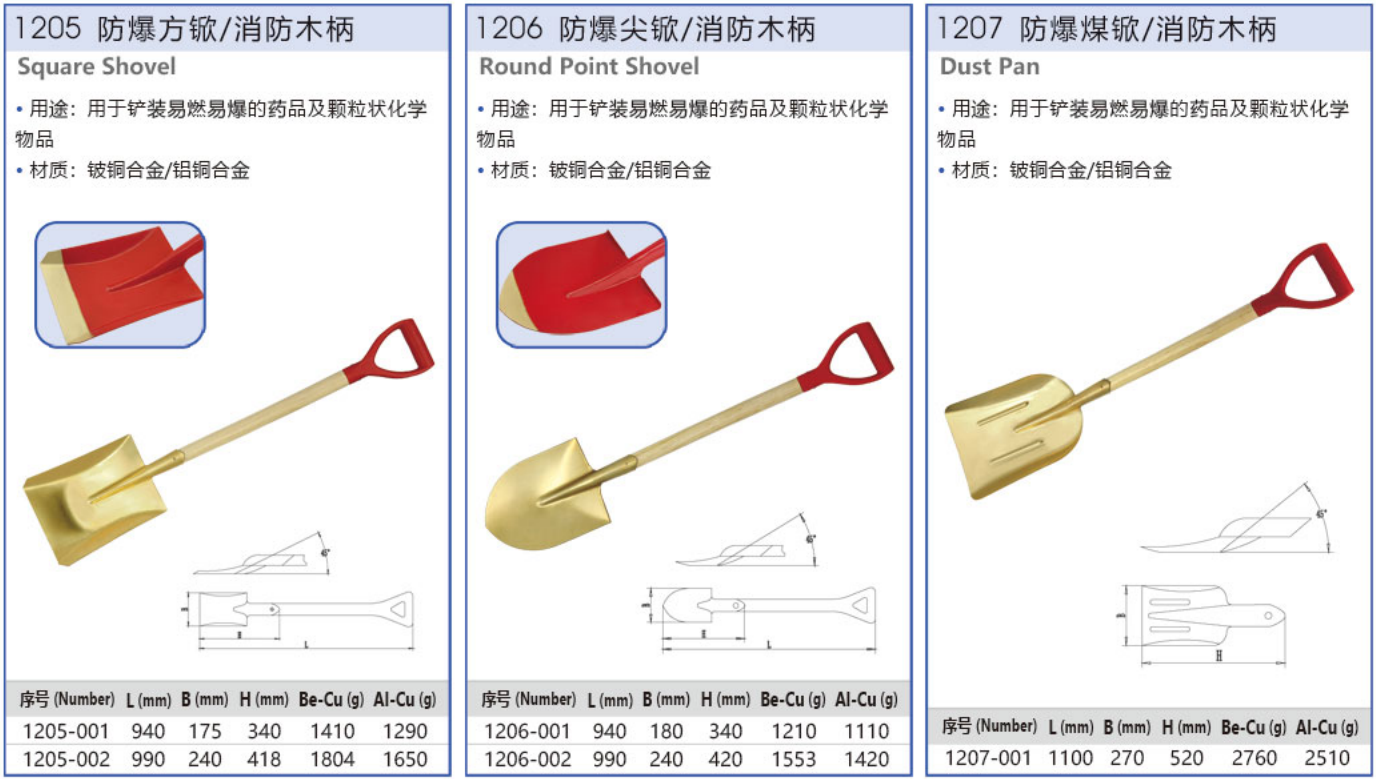

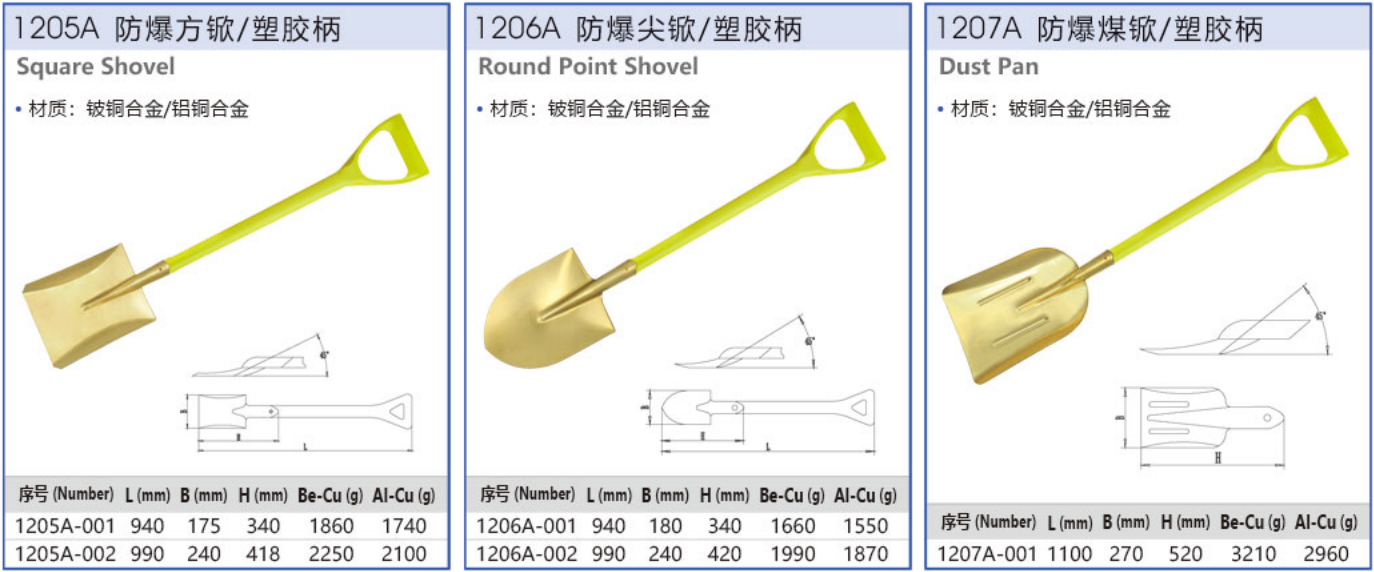

In addition, a variety of styles and handle options are available, which can be flexibly matched according to specific operating scenarios and usage habits:

|

Size |

D-type Wooden Handle |

Fiber Handle |

Long Wooden Handle |

|

Square Shovel/Square Spade |

175*340*940mm 240*418*990mm |

175*340*940mm 240*418*990mm |

175*340*1440mm 240*418*1490mm |

|

Round Point Shovel/Round Point Spade |

180*340*940mm 240*420*990mm |

180*340*940mm 240*420*990mm |

180*340*1440mm 240*420*1490mm |

|

Dust Pan/Coal Spade |

270*520*1100mm |

270*520*1100mm |

270*520*1600mm |

Conclusion: Safeguarding Every High-risk Operation with Professional Non-sparking Strength

From diverse safety features to full-scenario adaptability, from flexible material options to user-friendly style configurations, DeepLink Explosion-proof Shovel has always taken "safety, precision, and durability" as its core, providing customized non-sparking operation solutions for various high-risk industries. Whether for routine cleaning or high-intensity operations, whether for general non-sparking/explosion-proof scenarios or harsh civil explosive and metallurgical environments, DeepLink Non-sparking/Explosion-proof Shovel can serve as a "safety partner" for frontline operators with its reliable quality. Choosing DeepLink means choosing professional safety tools, making every high-risk operation safer and more efficient.