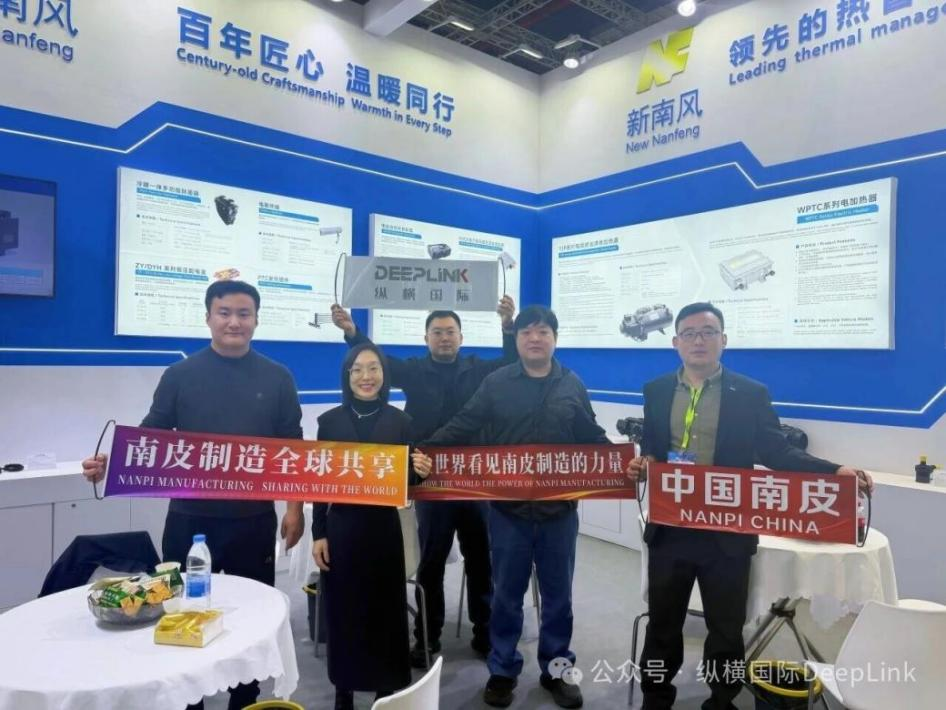

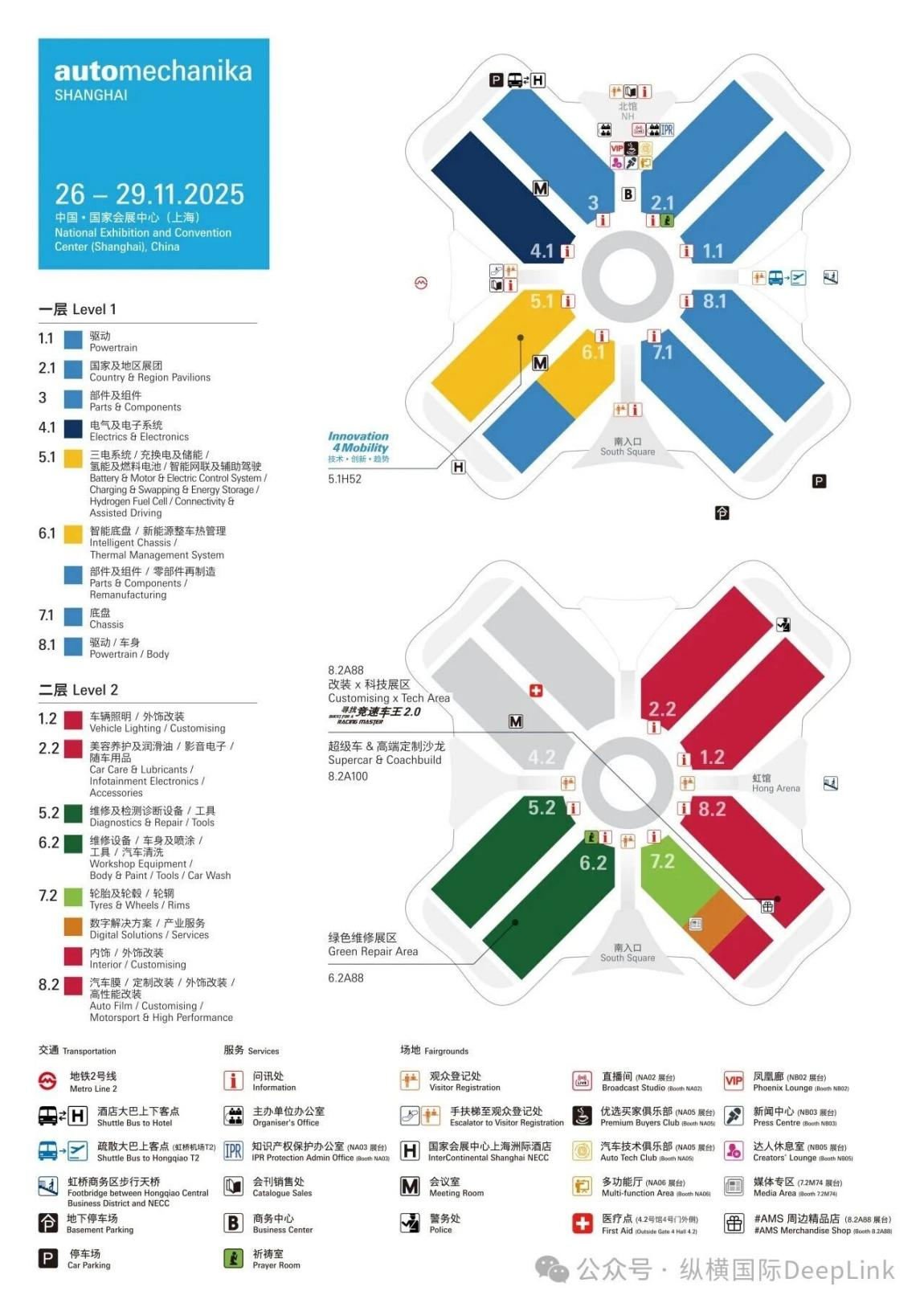

On November 26, 2025, the Automechanika grandly opened at the National Exhibition and Convention Center. As an international supply chain enterprise focused on the hardware, electromechanical, and metal processing industries, Cangzhou Deeplink International Supply Chain Co., Ltd. (hereinafter referred to as "Deeplink") made a splendid appearance as an exhibitor, showcasing its multiple mature processes and product series in the field of metal processing to a global clientele.

[Global Event, Precise Connection]

This edition of the exhibition was exceptionally large-scale, covering 15 halls with an exhibition area of 383,000 square meters, bringing together top technologies and innovative products from global fields including drive systems, electrical & electronics, tires & wheels, and green repair. Leveraging its deep understanding of the global hardware, electromechanical, and metal processing markets, Deeplink precisely targeted this platform to help partner enterprises explore broader international markets.

[Demonstrating Strength, Professional Empowerment]

At this exhibition, we prominently showcased the eight core process and service modules that constitute our competitive advantage:

· Metal Stamping Parts: Utilizing multi-station progressive dies and high-precision stamping equipment, we efficiently and economically mass-produce stamping parts with complex structures and tight tolerances, meeting the demands for consistency and reliability in structural components for industries like automotive and appliances.

· Sheet Metal Fabrication: We provide full-process customized sheet metal manufacturing services, from design optimization to finished product delivery. This includes chassis, enclosures, energy storage shells, and equipment guards, excelling in handling various materials and thicknesses to ensure structural strength and functionality.

· Laser Cutting Services: Equipped with high-power fiber laser cutting machines, we perform high-speed, high-precision 2D and 3D cutting on carbon steel, stainless steel, aluminum alloy, and other sheets, delivering smooth, burr-free edges ideal for subsequent bending and welding.

· Deep Drawn Parts: We specialize in manufacturing cup-shaped and shell-shaped parts with significant drawing depths and complex geometries. Our process capability effectively controls material flow, preventing wrinkling and cracking, making it suitable for products like automotive oil pans and various metal containers.

· Metal Bending Parts: Using high-precision CNC bending centers, we achieve accurate bends at various complex angles, ensuring minimal cumulative error in multi-stage bending – a key process for forming the final product's three-dimensional structure.

· Welding & Riveting Components: With professional capabilities in TIG welding, resistance welding, laser welding, and robotic welding, combined with expert riveting processes, we securely and aesthetically join multiple stamped or sheet metal parts into complex assemblies.

· CNC Machining Parts: As a complement to our stamping and sheet metal processes, our CNC machining centers perform precise milling, drilling, and tapping on complex 3D metal blanks, achieving higher dimensional accuracy and superior surface finish.

· Metal Brackets & Hooks: These products are typical examples of our comprehensive process capabilities. Starting from the customer's application scenario, we provide a full suite of services from load-bearing design and material selection to precision manufacturing, delivering products that combine structural strength and practicality.

By systematically displaying this complete "Metal Manufacturing Services" matrix, Deeplink clearly communicated to every visiting client that we are not just a supplier, but a manufacturing partner capable of deeply understanding requirements, possessing multi-process integration capabilities, and guaranteeing final product quality and delivery.

[Deepening Advantages, Building the Brand]

This participation was an important practice of Deeplink's service philosophy of "Fast Delivery, Exquisite Craftsmanship, Stable Quality." Our strengths demonstrated include:

· Full-Process Quality Control System: An international certified quality management system (e.g., SGS, ISO9001) ensures control from raw materials to finished products.

· Flexible Production Capability: Six automated production lines support flexible responses to orders of small, medium, and large batches.

· One-Stop Solution: We provide highly synergistic manufacturing services from drawing design, sample prototyping, to mass production and logistics distribution.

In the future, Deeplink will continue to deepen its expertise in the metal processing field. Through continuous participation in international exhibitions and deepened technological R&D, we will further strengthen our professional value within the global supply chain, providing reliable manufacturing services for more customers across various industries.