Dive deep into the core process of sheet metal bending and explore how Cangzhou Deeplink leverages advanced technology and full-industry-chain integration to accurately transform your designs into reality.

Metal bending is far more than just angling a sheet of metal. It is an art that combines materials science, engineering mechanics, and precision manufacturing. A precise bend determines the verticality of an enclosure, the seamless fit of assemblies, and the structural integrity and aesthetics of the final product. When choosing a bending service provider, you need more than just a bending machine—you need a partner who deeply understands material properties, precisely controls the process, and seamlessly integrates bending with subsequent steps. Deeplink is precisely such a partner. We elevate bending to a strategic level, ensuring every angle is perfectly accurate.

Part 1: Detailed Explanation of Metal Bending—From Principles to Key Technologies

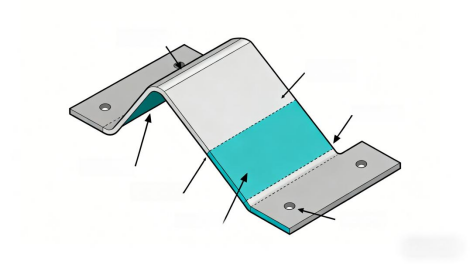

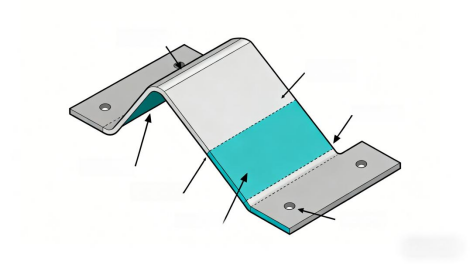

Bending is the process of applying pressure to a sheet metal part, causing it to undergo elastic deformation followed by plastic deformation, thereby forming specific angles and shapes.

-

Core Concepts:

-

Springback: This is the most critical challenge in bending. After bending, the material tends to slightly return to its original shape. Our engineers use experience and calculations to accurately predict springback, compensating through over-bending to ensure the final angle perfectly matches the design drawings.

-

-

Bend Radius:The choice of the inner bend radius is crucial, affecting the product’s strength, appearance, and assembly. We recommend the optimal bend radius based on material thickness and type.

-

Our Key Equipment and Technologies:

-

High-Precision CNC Press Brakes: Our bending centers are equipped with advanced CNC systems capable of storing thousands of die and program settings, ensuring extreme consistency in mass production.

-

-

Multi-Station Tooling Library: With a wide selection of upper and lower dies, we can handle everything from simple right-angle bends to complex multi-edge forming.

Part 2: Deeplink’s Bending Advantages—What Sets Us Apart

Our strength lies not only in our machines but also in how we integrate bending into a broader manufacturing ecosystem.

-

Full-Industry-Chain Integrated Service: Bending Is No Longer an Isolated Step

-

-

At Deeplink, bending is a core part of the sheet metal fabrication process. Your parts can move directly from high-precision laser cutting to bending without repositioning, ensuring unified benchmarks and high dimensional accuracy. After bending, processes like welding, riveting, or surface treatment can follow immediately. This integrated workflow significantly shortens lead times and reduces quality risks and management costs associated with intermediate steps.

-

Design and Manufacturing Collaboration: Professional DFM (Design for Manufacturability) Analysis

-

-

Our engineering team reviews your drawings before production, offering expert advice on bending processes. For example:

-

Avoiding Bending Interference: Recommending optimal bending sequences.

-

Structural Optimization: Suggesting reinforcements or process holes in stress concentration areas.

-

Cost Reduction: Optimizing designs to minimize bending steps and complexity.

- This ensures your design is not only innovative but also highly manufacturable.

-

Automation and Quality Assurance:

-

-

Our 6 automated production lines with 80% automation ensure efficient and stable bending processes. Automation reduces human error and guarantees consistency in mass production.

-

Our 39+ detection capabilities cover all key quality characteristics, from bend angles and dimensions to straightness. We adhere to international quality standards like ISO 9001:2015, ensuring every batch meets the strictest specifications.

-

Experience and Flexibility:

-

-

We specialize in bending various materials, from stainless steel and aluminum to carbon steel, understanding the unique properties of each.

-

Whether for OEM standard parts or highly customized complex components, we adapt flexibly to meet your needs from prototyping to mass production.

Conclusion: Choose a Professional Bending Partner to Lay a Solid Foundation for Your Product

Metal bending is the foundation of product structure. A precise and robust bend is the primary guarantee of product quality and reliability. By choosing Deeplink, you gain not just a bending service but a comprehensive manufacturing ally deeply committed to your project’s success.With our full-industry-chain integration, professional engineering support, automated production, and strict quality control, we ensure your sheet metal parts are perfectly managed from design to finished product.