CNC Machining or Laser Cutting: How to Choose the Right Machining Process for Your Parts?

In the world of part design and manufacturing, the success of an excellent design often hinges on selecting the right machining process. With various technologies like CNC Machining, Laser Cutting, and Metal Stamping available, many engineers and procurement managers face a common dilemma: Which process is the best fit for my project?

With over a decade of experience as a one-stop metal manufacturing solutions provider, Cangzhou Deeplink offers a clear guide to help you make an informed decision based on key factors.

Start by examining your part's blueprint, focusing on these geometric features:

Geometric Complexity:

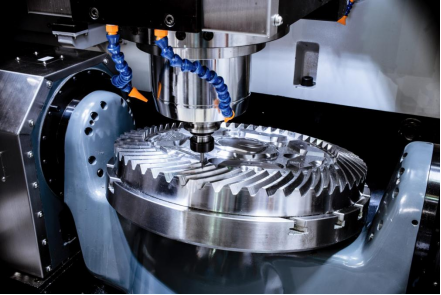

Complex 3D Surfaces/Organic Shapes: CNC Machining is ideal. Multi-axis CNC can create highly complex precision parts from a solid block of material, perfect for prototypes, molds, and intricate components.

Flat, 2D Profiles: Laser Cutting excels here. It quickly and accurately cuts complex shapes from sheet metal, ideal for panels, brackets, and more.

Simple Shapes, Holes, or Bosses: Metal Stamping is highly efficient. Using a dedicated die, it forms parts at high speed, perfect for high-volume production of items like washers and electronic contacts.

Wall Thickness & Detail:

Thin-Walled Parts/Enclosures: Sheet Metal Fabrication and Deep Drawing are specialized for forming metal sheets into boxes, housings, and containers.

Solid, Bulky Parts: These typically require CNC Milling or Turning from a solid block or thick plate.

Size & Tolerances:

For parts requiring extremely tight tolerances and precision fits, CNC Machining can achieve ±0.005mm or better.

Laser Cutting and Stamping offer good precision but are generally suited for less stringent tolerances than CNC.

Volume is a primary driver of cost and process selection.

Prototypes & Low Volumes (1 - 100 pcs):

Recommended: CNC Machining or Laser Cutting.

Why: No expensive tooling investment is required. Setup is quick, making the cost per part reasonable for small batches. Deeplink's rapid prototyping service is designed for this scenario.

Medium to High Volumes (1,000 - 100,000+ pcs):

Recommended: Metal Stamping or Deep Drawing.

Why: Although the initial cost for tooling (e.g., progressive dies) is higher, the cost per part plummets at volume, offering unbeatable efficiency for mass production.

Material Type:

CNC Machining and Laser Cutting are highly versatile, working with aluminum, steel, stainless steel, copper, titanium, and various plastics.

Stamping and Deep Drawing are best for ductile materials like aluminum, copper, and low-carbon steel sheets.

Surface Finish: The desired finish (e.g., anodizing, plating, sandblasting) can influence the choice. For instance, a CNC-milled part might need polishing, while a stamped part might be ready for assembly.

[Recommendation: Place a simple infographic here]

Part Requirement

→ Is it a complex 3D shape?

→ Yes → Choose CNC Machining

→ No → Is it a 2D flat profile?

→ Yes → Choose Laser Cutting

→ No → Is the production volume high?

→ Yes → Choose Metal Stamping/Deep Drawing

→ No → Does it require multiple processes?

→ Yes → Contact Deeplink for an Integrated Solution

Modern components often combine multiple processes. For example, an enclosure might require:

Laser Cutting for the main panel.

Sheet Metal Bending for the walls.

CNC Machining for precise connector ports.

Welding for final assembly.

This is where Cangzhou Deeplink International Supply Chain Co., Ltd. provides a distinct advantage. We integrate a full range of processes under one roof, including CNC Machining, Laser Cutting, Metal Stamping, Sheet Metal Fabrication, Deep Drawing, and Welding & Riveting.

You don't need to be an expert in every process or manage multiple suppliers. Simply share your design and goals, and our engineering team will:

Perform a Design for Manufacturability (DFM) analysis to optimize your design.

Recommend the most cost-effective and efficient process combination.

Deliver finished components under a unified quality control system.

Still Unsure About the Best Process for Your Part?

Let Deeplink's Expert Engineers Provide a Free Technical Analysis! Send us your part drawings or requirements. We will recommend the optimal manufacturing strategy and provide a competitive quotation.

[Button: Contact Our Engineers for a Free Quote]