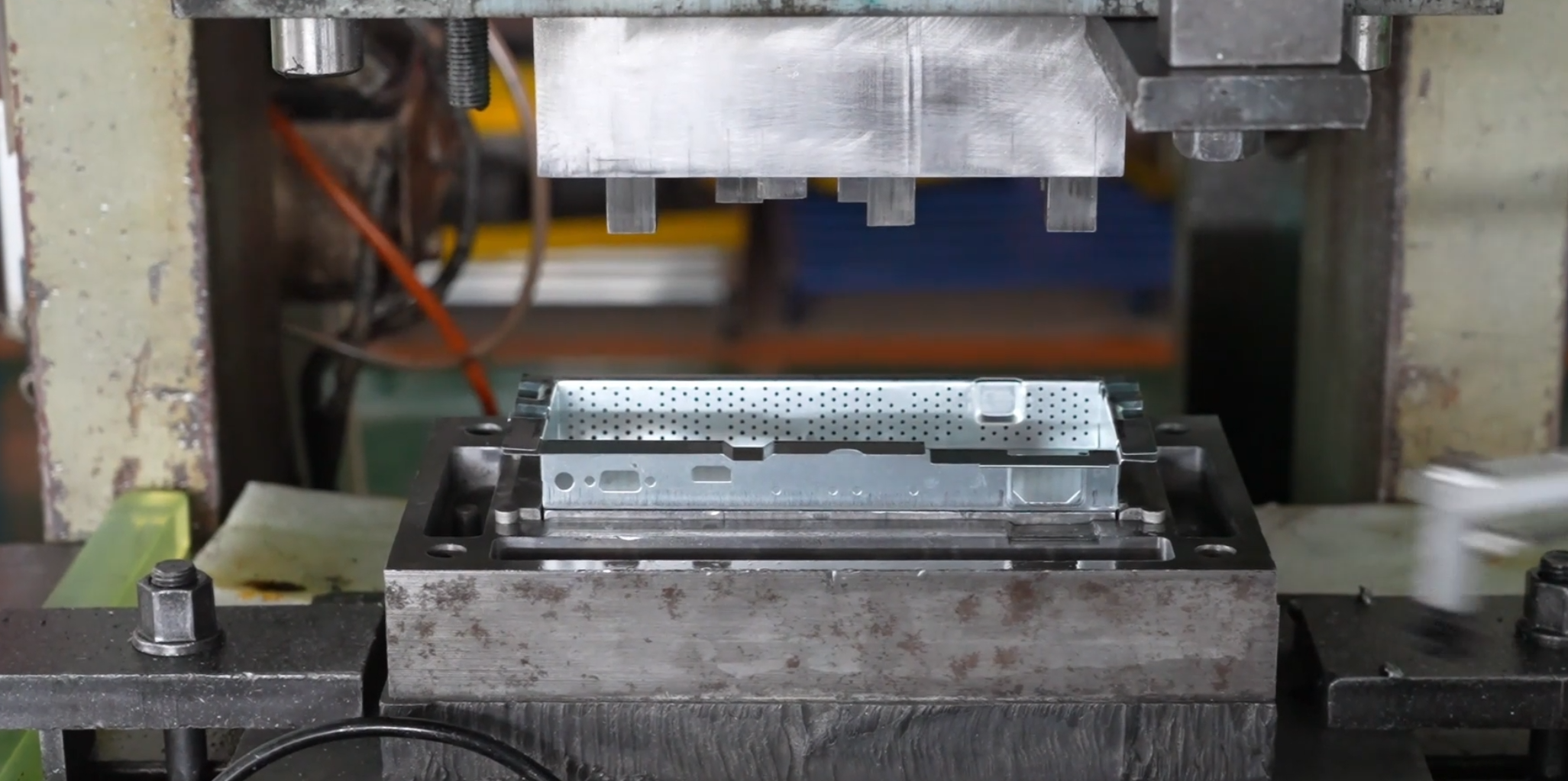

Metal stamping deburring is a critical post-processing step to ensure precision, safety, and functionality in stamped metal parts. Burrs—tiny raised edges or imperfections formed during stamping—can compromise part performance, cause assembly issues, or even pose safety risks.

Deburring refers to the removal of unwanted burrs from metal components after stamping. These burrs arise due to material deformation during cutting or punching. Effective deburring enhances part longevity, reduces friction in assemblies, and improves aesthetics. Common applications include automotive components, aerospace parts, and electronics enclosures.

Mechanical methods, such as vibratory tumbling or abrasive blasting, use physical force to grind away burrs. Ideal for high-volume production, these techniques ensure uniform results but may require post-cleaning to remove residual abrasive particles.

Thermal Energy Method (TEM) employs a combustive gas mixture to burn off burrs in milliseconds. Suitable for complex geometries, TEM leaves no mechanical stress but requires precise control to avoid part distortion.

This method uses electrolysis to dissolve burrs selectively. It’s ideal for delicate components where mechanical contact could cause damage.

Hand tools like files or deburring knives are cost-effective for small batches but labor-intensive. Consistency depends heavily on operator skill.

Liquid nitrogen embrittles burrs, making them easy to remove via mechanical vibration. This method is eco-friendly and effective for plastics and metals.

Research on machining parameters (e.g., cutting speed, pressure) highlights their impact on surface integrity. For instance, higher cutting speeds in milling operations increase tool wear and surface roughness1. Similarly, in deburring:

Pressure Control: Excessive force in mechanical methods can cause micro-cracks.

Temperature Management: Thermal methods require precise heat thresholds to avoid material degradation.

Time Efficiency: Automated systems, like robotic deburring, reduce cycle times while maintaining consistency.

Post-deburring inspections ensure compliance with industry standards like ASME Y14.5. Key metrics include:

Surface Roughness (Ra): Measured via profilometers; lower Ra values indicate smoother surfaces.

Edge Radius: Critical for parts subjected to fatigue loads.

Adhesion Testing: Ensures coatings (if applied) adhere properly to deburred surfaces.

Automotive: Deburred transmission components reduce wear and noise.

Medical Devices: Burr-free surgical instruments prevent contamination.

Electronics: Precision connectors require flawless edges for optimal conductivity.