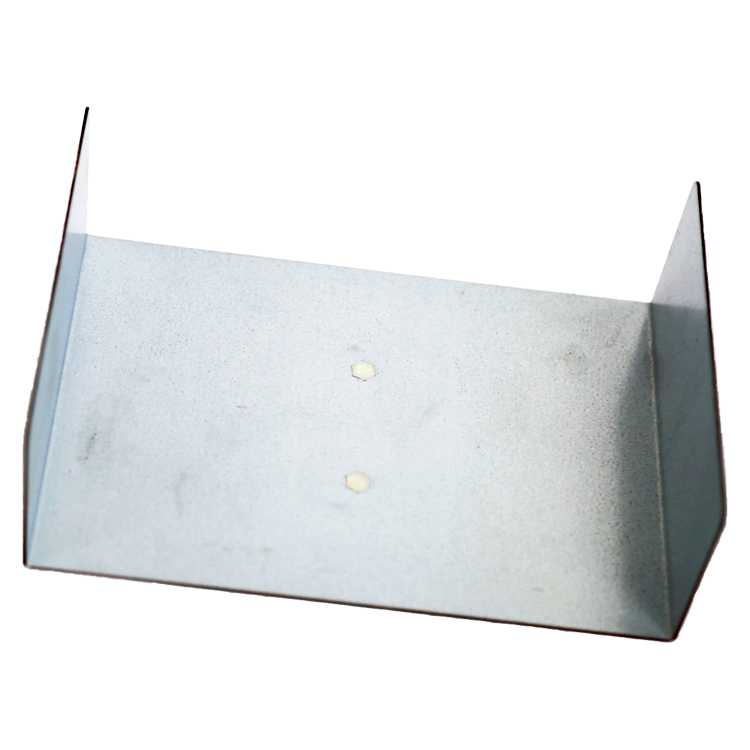

Bending dies for sheet metal play a crucial role in the manufacturing process, particularly in industries that require precision and efficiency. At Cangzhou Deeplink International Supply Chain Company, we specialize in producing high-quality bending dies designed to meet the demands of global manufacturers. Our dies are engineered to provide consistent performance, ensuring that each bend is executed with accuracy.

The importance of choosing the right bending die cannot be overstated. A well-designed die not only improves the quality of the finished product but also enhances the overall efficiency of the production line. Our bending dies are compatible with various types of sheet metal, allowing for versatility in applications ranging from automotive to aerospace.

We take pride in our commitment to quality and customer satisfaction. Our manufacturing processes adhere to strict quality control standards, ensuring that every die we produce meets the highest benchmarks. With our bending dies, you can expect durability, precision, and a significant reduction in production downtime.

In addition to our standard offerings, we also provide custom solutions to cater to the unique needs of our clients. Whether you need a specific size, shape, or material, our team is ready to collaborate with you to develop the perfect bending die for your application. Our dedication to innovation and excellence makes us a trusted partner in the hardware and electromechanical industry.