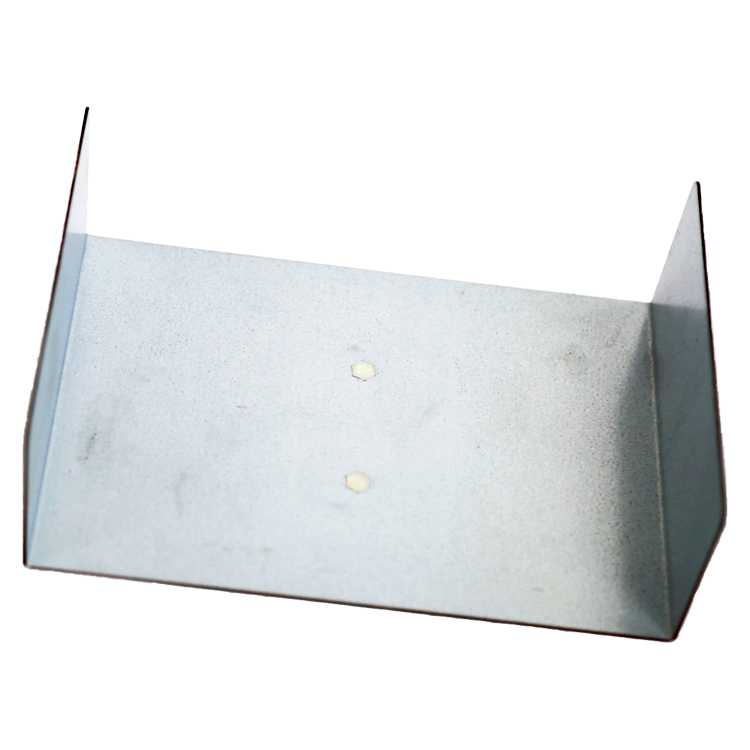

Metal bending parts are integral components in various industries, including automotive, aerospace, and electronics. At Cangzhou Deeplink, we specialize in producing high-quality metal bending parts that are essential for the functionality and durability of your products. Our expertise in metal bending allows us to create components that not only meet but exceed industry standards.

The process of metal bending involves deforming metal sheets or rods into desired shapes using various methods such as air bending, bottoming, and coining. Each method offers unique advantages, allowing us to cater to different specifications and requirements. Our skilled technicians utilize advanced technologies to ensure that every part is manufactured with precision, resulting in exceptional fit and finish.

We understand that different industries have varying needs, and our metal bending parts are designed to accommodate a wide range of applications. From intricate designs to heavy-duty components, we are equipped to handle projects of any scale. Our commitment to quality and customer satisfaction drives us to continuously improve our processes and product offerings.

As a global supplier, we recognize the importance of cultural sensitivity and adaptability. Our team is well-versed in international standards and practices, enabling us to serve diverse markets effectively. We prioritize clear communication and collaboration with our clients to ensure that their unique needs are met throughout the production process.