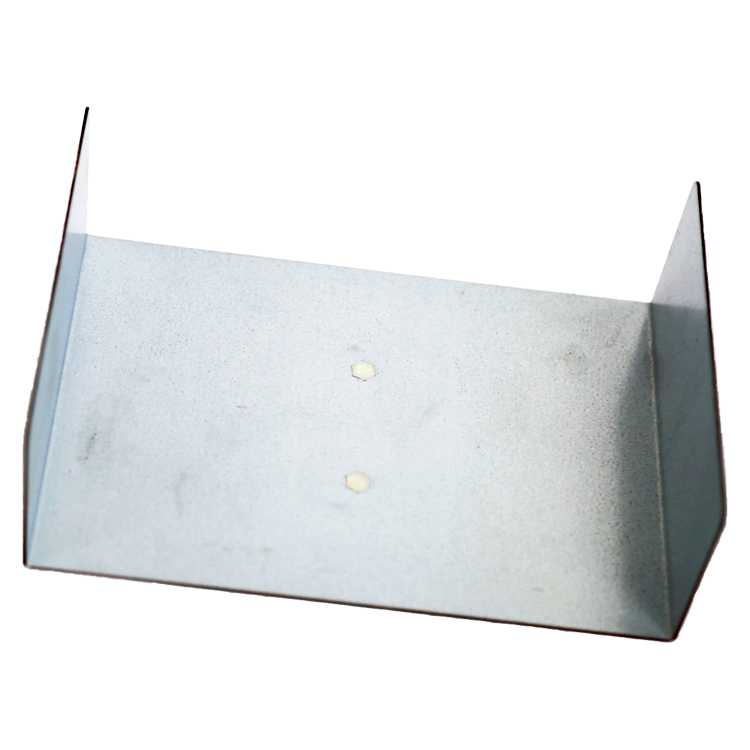

Edge bending sheet metal is a crucial component in various manufacturing sectors, particularly in the hardware and electromechanical industries. At Cangzhou Deeplink International Supply Chain Company Limited, we excel in producing edge bending sheet metal that meets the highest standards of quality and precision. Our products are designed to facilitate complex designs while maintaining structural integrity, making them ideal for applications ranging from automotive parts to intricate machinery components.

The edge bending process involves bending the metal at specific angles to create precise shapes that are essential for modern manufacturing. Our state-of-the-art facilities are equipped with the latest technology to ensure that each piece of sheet metal is processed with the utmost care and precision. We understand that in today's competitive market, the ability to deliver high-quality products quickly is vital. Therefore, we have streamlined our production processes to ensure fast turnaround times without compromising on quality.

Furthermore, our commitment to sustainability means that we prioritize eco-friendly practices in our manufacturing processes. By utilizing recyclable materials and minimizing waste, we not only provide superior products but also contribute to a more sustainable future. Our edge bending sheet metal solutions are designed to meet the diverse needs of our international clientele, ensuring that we can support various industries with tailored offerings that enhance their production capabilities.