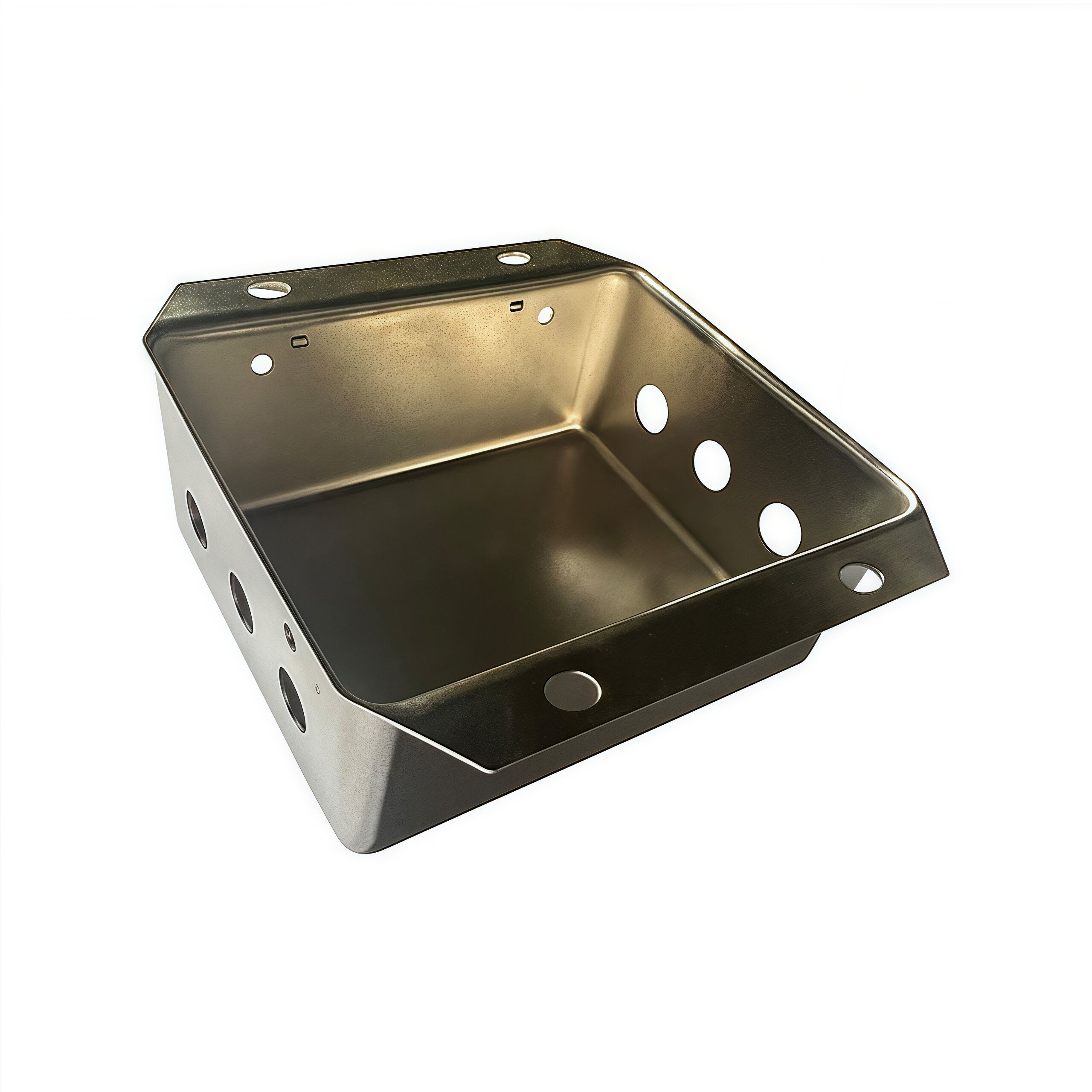

Custom deep drawn parts are integral to various applications across multiple industries, including automotive, aerospace, and electronics. These components are created through a process that involves forming a flat sheet of metal into a three-dimensional shape, ensuring both strength and lightweight properties. At Cangzhou Deeplink, we utilize advanced deep drawing techniques that allow us to produce intricate designs with high precision.

Our deep drawn parts are crafted from a variety of metals, including stainless steel, aluminum, and brass, providing options that cater to different environmental conditions and applications. The versatility of our products makes them suitable for use in high-stress environments, where durability and reliability are paramount. We emphasize the importance of adhering to international quality standards, ensuring that our products not only meet but exceed client expectations. By focusing on innovation and quality, we aim to support our clients in achieving their manufacturing goals efficiently and effectively.