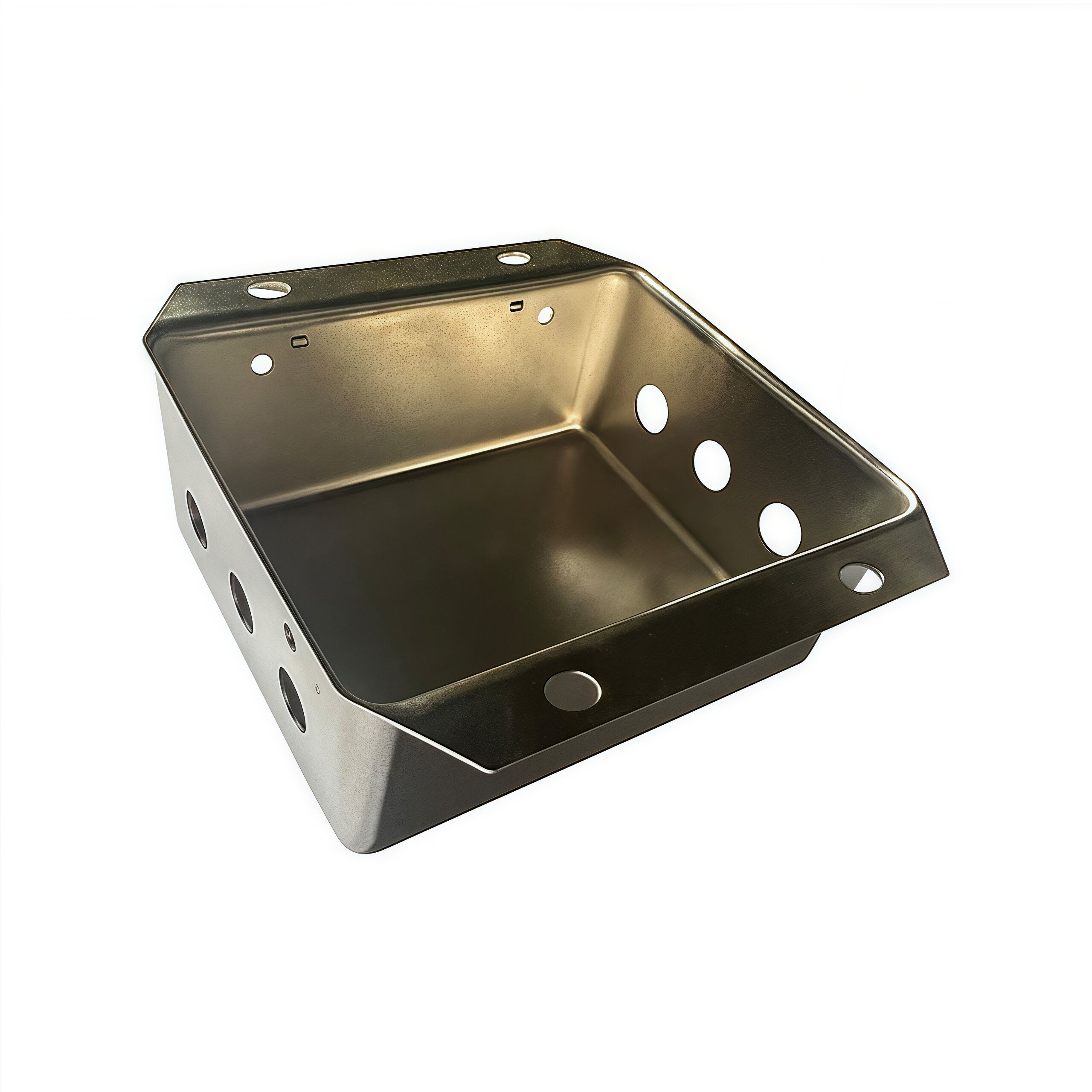

Highstrength deep drawn parts are essential components in the hardware and electromechanical sectors, where precision and reliability are non-negotiable. At Cangzhou Deeplink International Supply Chain Company Limited, we leverage advanced manufacturing techniques to produce parts that meet the highest standards of quality and performance. Our deep drawing process involves transforming flat metal sheets into intricate shapes through a series of controlled stamping and stretching operations. This method not only enhances the strength of the material but also allows for complex geometries that are difficult to achieve through traditional machining methods.

Our highstrength deep drawn parts are widely used in various applications, including automotive, aerospace, and industrial machinery. The robust nature of these components ensures they can withstand extreme conditions, making them suitable for critical applications. Additionally, our commitment to sustainability means we use eco-friendly practices in our production processes, aligning with global efforts for a greener future. By choosing our highstrength deep drawn parts, clients gain access to a product that not only meets their technical requirements but also supports their corporate social responsibility goals.