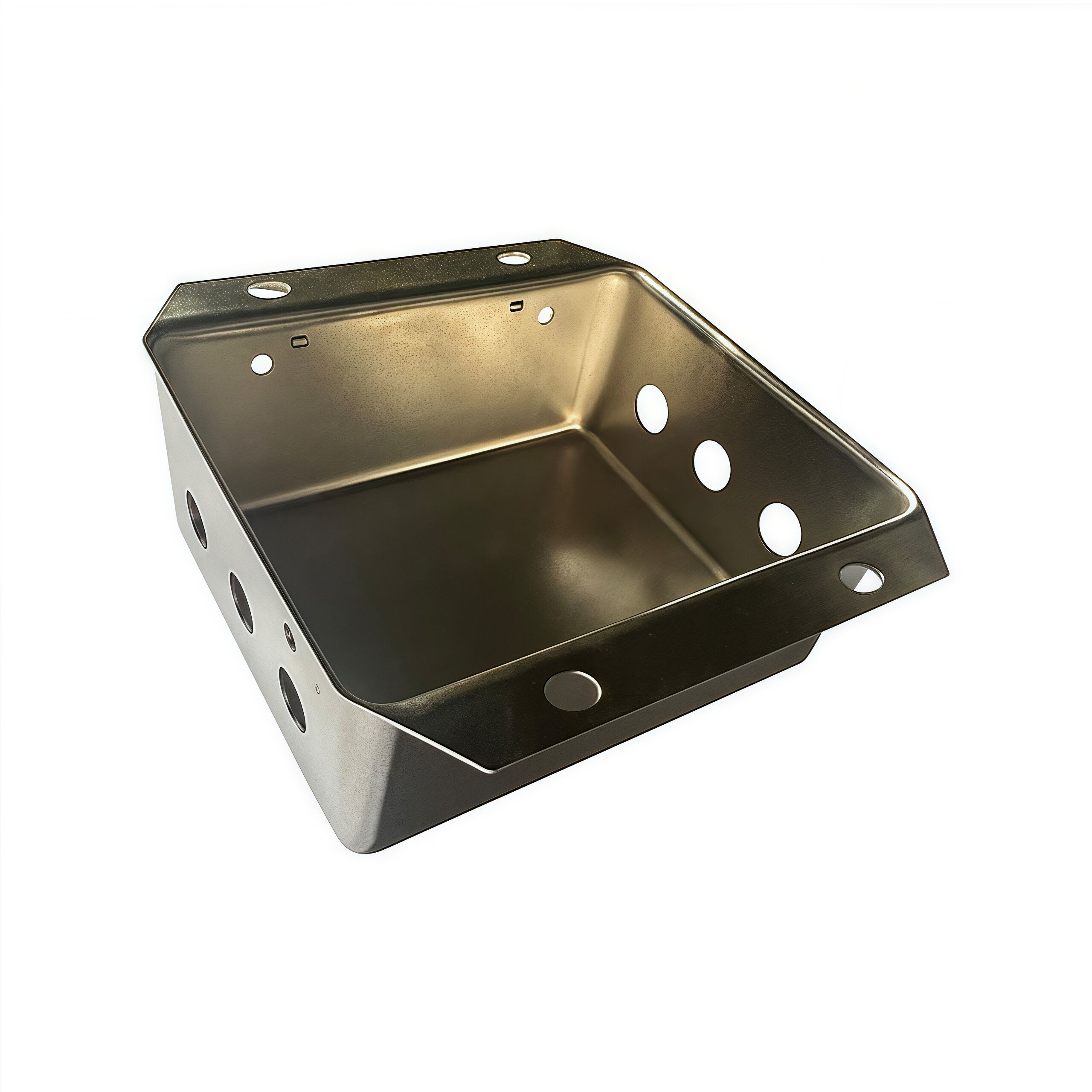

Highprecision deep drawn parts are essential components in modern manufacturing, providing the necessary support and functionality across various industries. These parts are produced through a specialized process that involves forming sheet metal into desired shapes using a die and punch method. This technique allows for the creation of complex geometries with high dimensional accuracy and excellent surface finish, making them ideal for applications in automotive, aerospace, electronics, and more.

Cangzhou Deeplink International Supply Chain Company Limited stands out in the competitive landscape by offering highprecision deep drawn parts that are not only reliable but also cost-effective. Our commitment to using cutting-edge technology and adhering to international quality standards ensures that our products meet the evolving demands of the global market.

By choosing our highprecision deep drawn parts, clients benefit from enhanced product performance, reduced assembly times, and improved overall efficiency in their manufacturing processes. We prioritize customer satisfaction and work closely with our clients to understand their unique requirements, enabling us to deliver tailored solutions that drive their success.