Deep draw components are essential in various manufacturing processes, particularly in industries such as automotive, aerospace, and electronics. These components are produced through a specialized metal forming process that allows for the creation of complex shapes and designs with high precision. At Cangzhou Deeplink International Supply Chain Company Limited, we pride ourselves on our ability to deliver top-quality deep draw components that cater to the diverse needs of our global clientele.

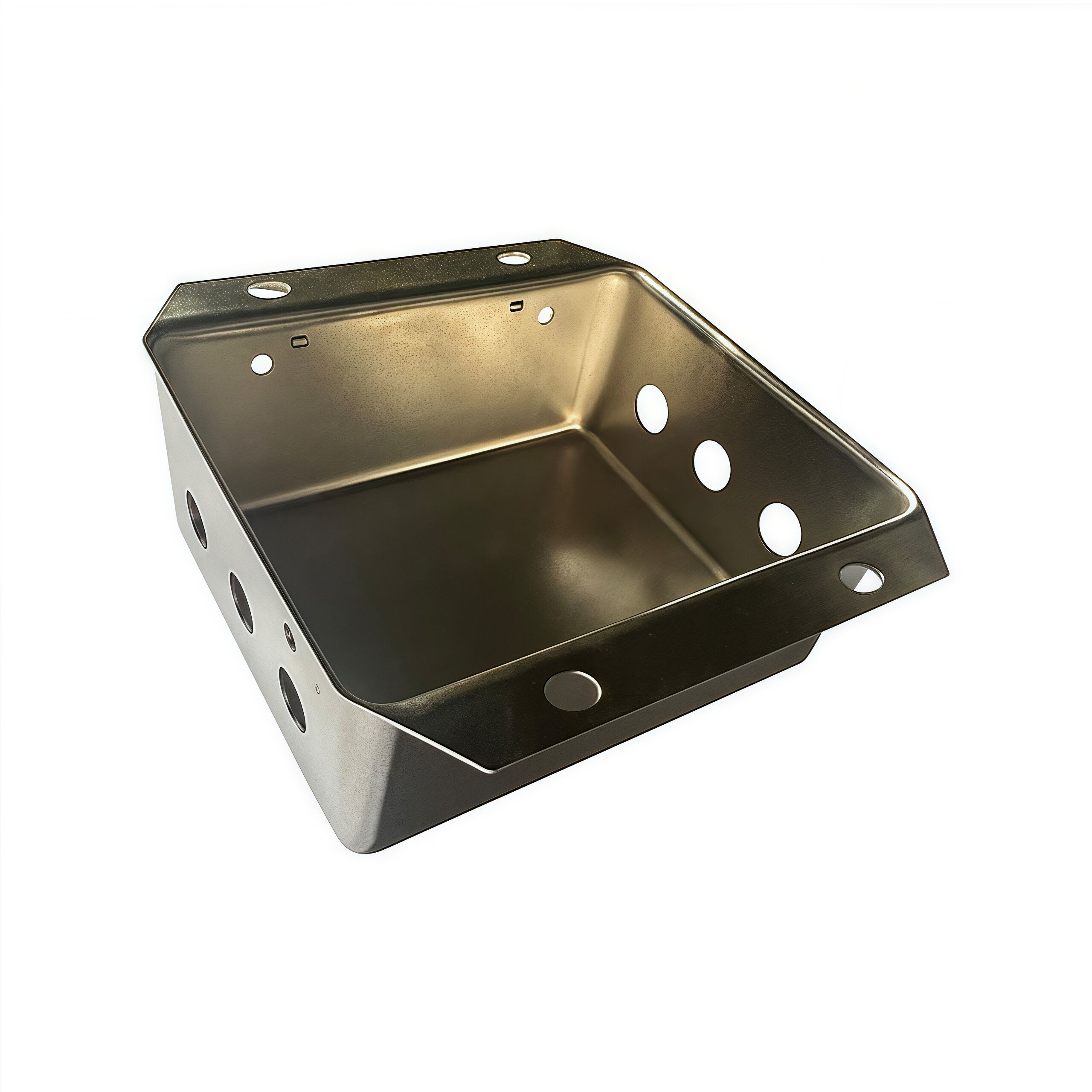

Our deep draw components are characterized by their exceptional strength and durability, making them suitable for high-stress applications. The process involves drawing a flat metal sheet into a desired shape, which not only optimizes material usage but also enhances the structural integrity of the final product. This method is particularly advantageous for producing parts that require intricate designs or that must withstand significant mechanical stress.

Furthermore, our deep draw components are available in various materials, including stainless steel, aluminum, and copper, allowing us to meet the specific requirements of different industries. We understand that each client has unique specifications, which is why we offer customization options to ensure that our products align perfectly with your operational needs.

By choosing our deep draw components, you are investing in quality, reliability, and efficiency. Our commitment to excellence and customer satisfaction positions us as a trusted partner in your manufacturing journey, ensuring that you receive the best solutions tailored to your specific requirements.