Material Selection and Its Impact on Metal Bending Parts Quality

Common Materials Used in Metal Bending: Steel, Aluminum, Stainless Steel, Copper, and Brass

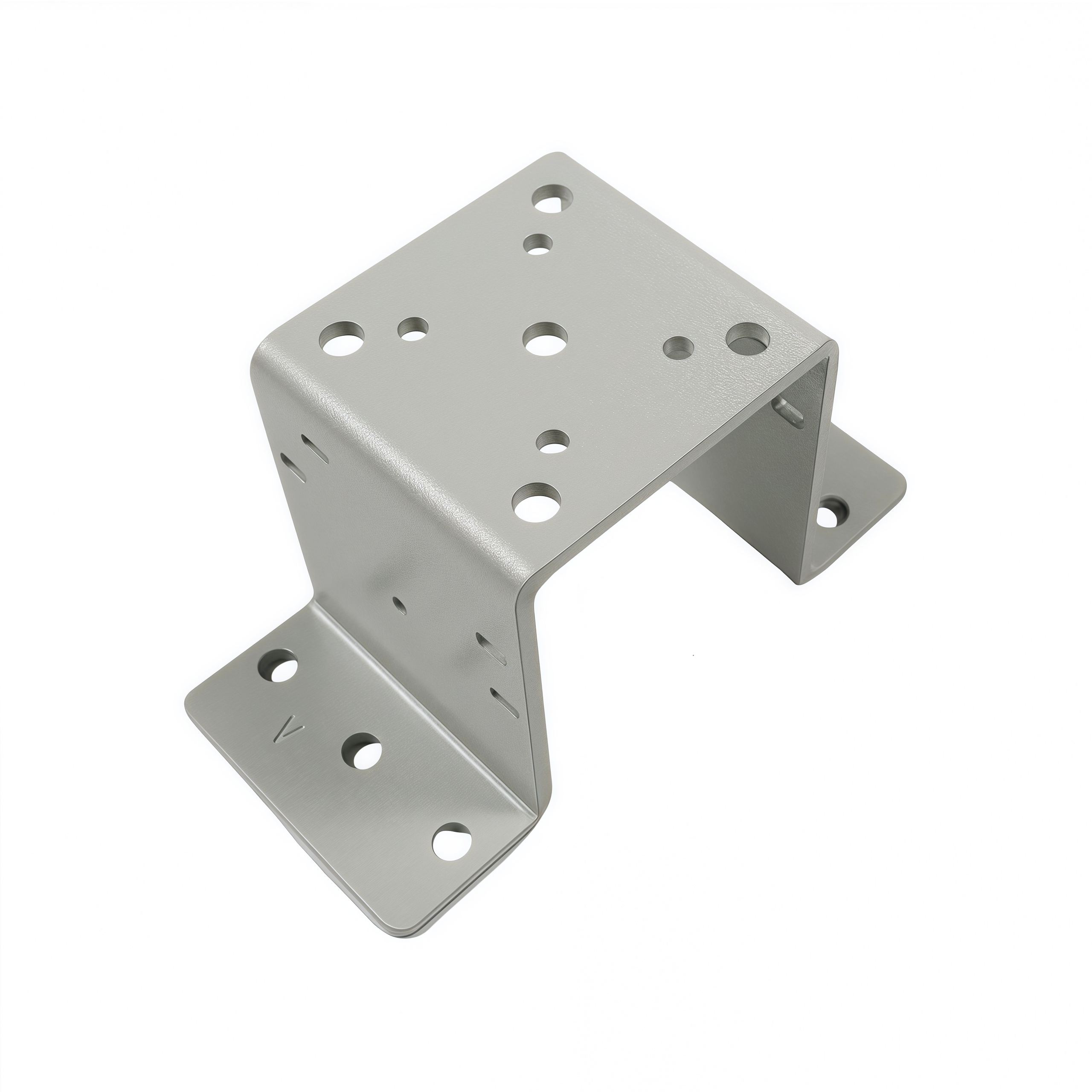

The choice of material directly determines the performance and cost-effectiveness of metal bending parts. Five metals dominate industrial applications:

| Material | Tensile Strength (MPa) | Bendability | Springback Risk | Primary Use Cases |

|---|---|---|---|---|

| Carbon Steel | 400-550 | Moderate | Low | Automotive frames, machinery |

| Aluminum | 70-200 | High | High | Aerospace panels, electronics |

| Stainless Steel | 500-1,000 | Low | Moderate | Food processing, medical systems |

| Copper | 200-300 | High | Moderate | Electrical connectors, HVAC |

| Brass | 300-400 | Moderate | Low | Marine hardware, decorative trim |

Aluminum accounts for 42% of lightweight bending applications due to its malleability, while stainless steel's corrosion resistance makes it ideal for harsh environments.

How Material Properties Affect Bendability, Springback, and Part Integrity

How much a material stretches before breaking and how strong it gets when stressed determines how it behaves during bending operations. Take aluminum for instance its relatively weak tensile strength lets manufacturers bend it into tighter curves, but they need to apply around 15 to 25 degrees extra angle to make sure it stays bent after forming according to research published last year by Forming Technology magazine. Stainless steel presents different challenges because it hardens so quickly during processing, needing about 30 percent more force than regular carbon steel does, which means tools get worn out faster in production settings. Copper and brass materials strike a nice balance between electrical properties and ease of shaping, although their internal grain patterns aren't uniform across all directions. This makes them prone to cracking if bent randomly instead of following specific directional guidelines during fabrication processes.

Case Study: Aluminum vs. Stainless Steel in Precision Enclosures

One medical equipment maker cut enclosure flaws down around 30 percent when they swapped out 6061 aluminum for 316L stainless steel in their production line. Sure, aluminum saved money on transportation because it weighs so much less, but those savings disappeared fast when they started seeing pits forming after repeated sterilizations. Switching materials came at a price too though, with bending operations costing about 18% more in energy. Still worth it in the long run though, since parts lasted nearly three times longer before needing replacement. Looking back, this experience shows how picking the right material isn't just about what looks good on paper. For companies making devices that need to survive harsh cleaning processes day after day, factors like resistance to chemicals and overall toughness often trump initial cost savings from lighter materials.

Bending Processes and Their Influence on Precision and Consistency

Key Metal Bending Techniques: V-Bending, Roll Bending, and Rotary Bending

Today's manufacturing shops typically use three main approaches when it comes to forming metal bends. There's V-bending for those straightforward right angle jobs, roll bending which works great for things like pipe curves, and then there's rotary bending that handles all sorts of complicated shapes across multiple axes. The problem with all these methods is what we call springback, basically when metal tries to snap back to where it was before being bent. Some studies indicate that stainless steel can bounce back anywhere from 4 to 7 degrees during regular air bending operations, but if they switch to coining techniques instead, those errors shrink down under 1 degree. For companies working on aircraft components needing flawless curves, roll bending remains the go to choice. Meanwhile automotive makers rely heavily on rotary bending because it delivers around plus or minus quarter of a degree consistency for their bracket assemblies.

CNC Press Brakes: Achieving High Repeatability and Tight Tolerances

Press brakes controlled by CNC technology can hit positional accuracy down to 0.01 mm thanks to their linear encoder feedback systems. Such precision makes all the difference when producing metal bends in big quantities, especially important for sectors like electronics manufacturing where enclosures need tolerances tighter than ±0.1 mm. The newer models come equipped with smart features that adjust on their own for things like changes in material hardness, which cuts down setup time dramatically about two thirds faster than what's possible with manual presses. Industry data from last year shows operators working with these CNC brakes get around 98.7 percent success rate on the first try when shaping aluminum chassis parts, something that really matters in high volume production runs.

Balancing Speed and Accuracy in Industrial Bending Operations

High-volume factories optimize bending workflows through:

- Tooling standardization: Reducing die changeovers by 40–50%

- Adaptive bending algorithms: Adjusting parameters mid-run for temperature shifts

- Inline laser measurement: Detecting angle deviations in 0.5-second cycles

These strategies maintain throughput above 1,200 bends/hour while keeping scrap rates below 0.8%, even with challenging materials like tempered brass. Process simulations suggest combining servo-electric drives with real-time thickness monitoring could achieve micron-level accuracy for medical components by 2026.

Design Principles That Enhance Quality of Metal Bending Parts

Optimizing Bend Radius, K-Factor, and Tolerance for Reliability

Getting consistent quality starts right at the design stage. Research indicates that when working with aluminum alloys, maintaining a bend radius of at least 1.5 times the material thickness cuts down on cracking risks by around 40%. For steel materials, the minimum acceptable ratio drops to just 1 times thickness. The so-called K factor, which basically tells us where the neutral axis sits when metal gets bent, changes depending on how ductile the material is. Stiff stuff like stainless steel usually has a K factor around 0.3, whereas softer metals such as brass tend toward 0.5. When manufacturing parts that need to be exactly the same every time, tight tolerances matter a lot. CNC press brakes can achieve ±0.1 mm precision, something absolutely critical for components used in aircraft brackets or medical device housings where even tiny variations could spell disaster.

Preventing Cracking and Deformation Through Smart Design

Stress concentration at bend lines causes 67% of part failures in high-cycle applications. Effective strategies include:

- Bend relief cuts: Widths of 1.5x material thickness reduce tearing in copper electrical contacts

- Grain alignment: Bending perpendicular to the rolling direction improves stainless steel's elongation by 30%

- Wall thickness ratios: Maintaining a 3:1 thickness-to-bend length ratio prevents distortion in automotive chassis components

The Role of Wall Thickness and Grain Direction in Bend Performance

When working with structural steel that has walls over 4 mm thick, bigger bend radii are necessary to reduce springback issues during fabrication. On the flip side, those slim electronic enclosures with walls between 0.8 and 1.2 mm work best when manufacturers use laser etching for bend lines since this gives much better precision control. According to finite element analysis studies, there's actually an interesting finding about aircraft grade aluminum too. Bending it against the grain direction seems to boost fatigue resistance around 18 percent compared to other methods. This makes a real difference for parts like wing spars that experience constant stress cycles throughout their service life.

Quality Control Methods for Consistent Metal Bending Parts

Dimensional Inspection and Angle Verification During Production

Most manufacturers rely on laser scanners along with those coordinate measuring machines, commonly called CMMs, when they need to check if bend angles fall within that tight ±0.5 degree tolerance range. According to a recent report from the Precision Machining Association back in 2023, shops that implemented angle checks during production actually saw their rework rates drop around 40 percent compared to those waiting until after manufacturing was complete. For monitoring wall thickness throughout the process, air gauges work pretty well alongside optical comparators. These tools are absolutely necessary when making hydraulic parts where getting those internal clearances right matters so much for proper function.

Detecting Surface Defects: Cracking, Warping, and Finish Issues

Dye penetrant inspection can spot those tiny cracks that just won't show up when looking at parts with the bare eye. Meanwhile, structured light scanning technology measures how flat surfaces really are down to about 0.02 millimeters. Some major automotive component manufacturers saw their warranty claim numbers drop by around 35 percent once they started using automated visual inspection systems capable of picking out those annoying orange peel textures on painted surfaces. For structural components that need to hold weight, combining traditional Brinell hardness tests with careful examination of metal grain structures goes a long way toward stopping unexpected failures caused by internal stresses building up over time.

Statistical Process Control and In-Line vs. Post-Process QA

Monitoring force in real time on press brakes sends important data to control charts so operators can make changes before thickness variations go beyond the ±1.5% range. The latest ASME Quality Benchmark numbers from 2023 show that shops which implement in line statistical process control hit around 99.2% first pass yields compared to just 86% when relying on traditional batch inspections. For those working with copper contacts in high volume production runs, thermal imaging technology is making a big difference these days. It actually tracks how materials respond to work hardening during repeated bends and then adjusts for springback automatically by looking at all the strain data collected over time.

Applications of Metal Bending Parts Across Key Industries

Automotive and Aerospace: Frames, Brackets, and High-Strength Jet Engine Components

The metal bending parts really hold everything together in cars and planes these days. Manufacturers work with high strength steel and titanium alloys to create all sorts of components like lightweight car frames, suspension parts for vehicles, and those intricate pieces inside jet engines. Getting those measurements right matters a lot too since anything off by just 0.1 mm can throw off how air flows over surfaces and affect fuel consumption rates. When it comes to making those titanium turbine housings, CNC rotary bending actually cuts down on something called springback by about 40 percent when compared with older manual techniques. This makes a big difference in quality control for aerospace manufacturers who need consistent results every single time they produce parts.

Electronics: Compact, High-Tolerance Enclosures and Chassis

The electronics industry relies on aluminum and copper bends to balance thermal conductivity with structural integrity. Press-brake forming achieves 0.05° angular consistency in server enclosures, preventing electromagnetic interference while dissipating heat from high-density circuits. Recent advancements in laser-guided bending have reduced microcracking in 5G antenna housings by 22%.

Construction: Structural Supports and Architectural Metalwork with Corrosion Resistance

The use of galvanized steel arches alongside stainless steel facades shows how metal bending plays a significant part in big construction projects. When it comes to bridge building, roll bending creates those long structural beams that resist corrosion, especially when coated with zinc aluminum mixtures. These coatings can last well beyond half a century even in harsh coastal conditions where salt air would normally eat away at materials. For architects wanting curved panels without warping issues, cold forming has become essential. The process keeps dimensional changes under control, typically below 1% deviation across lengths that stretch past 15 meters. This level of precision makes all the difference when creating sleek modern structures that need both form and function.

FAQ Section

What are the common materials used in metal bending?

Common materials used in metal bending include carbon steel, aluminum, stainless steel, copper, and brass each offering unique properties for specific applications.

How do material properties affect bendability and springback?

Material properties such as tensile strength and ductility affect how easily a material can be bent and the degree of springback, which is the tendency for the material to return to its original shape after bending.

What are key metal bending techniques used in manufacturing?

Key metal bending techniques include V-bending, roll bending, and rotary bending each suited for different shapes and applications.

How does CNC technology improve bending precision?

CNC technology improves bending precision by allowing for positional accuracy down to 0.01 mm, crucial for high-volume production requiring tight tolerances.

What are quality control methods for metal bending parts?

Quality control methods include dimensional inspection, angle verification, surface defect detection, and statistical process control to ensure consistent and defect-free bending operations.

Table of Contents

- Material Selection and Its Impact on Metal Bending Parts Quality

- Bending Processes and Their Influence on Precision and Consistency

- Design Principles That Enhance Quality of Metal Bending Parts

- Quality Control Methods for Consistent Metal Bending Parts

- Applications of Metal Bending Parts Across Key Industries

- FAQ Section