On October 15th, Cangzhou DEEPLINK International Supply Chain Co., Ltd. (hereinafter referred to as "DEEPLINK") made a grand appearance at the 134th China Import and Export Fair (Canton Fair). As a supply chain service provider deeply engaged in the fields of metal sheet metal processing and precision manufacturing, DEEPLINK accurately met the needs of global customers with its professional technical solutions and mature manufacturing capabilities during the fair, and successfully invited key customers to conduct on-site factory audits at its production base. After in-depth inspections and technical exchanges, the two parties signed a long-term supply cooperation agreement on-site, achieving a leap from intentional communication to formal contract signing.

In the exhibition hall of the Canton Fair, DEEPLINK focused on demonstrating its sheet metal processing capabilities across multiple fields, covering products such as chassis and cabinets, precision metal structural parts, and auto parts. The company's team not only presented a one-stop process chain—from laser cutting and CNC stamping to bending forming and welding assembly—through physical samples, but also provided detailed technical solutions and case analyses for industry pain points that customers generally care about, including laser cutting accuracy, stamping deformation control of stainless steel and aluminum plates, and welding strength and deformation control. This attracted many international buyers to stop and communicate.

Among them, customers from the Middle East showed strong interest in DEEPLINK's capabilities in high-precision laser cutting (with an accuracy of up to ±0.1mm) and integrated forming of complex sheet metal parts. To further verify the production process and quality management system, DEEPLINK specially invited them to conduct an in-depth factory audit.

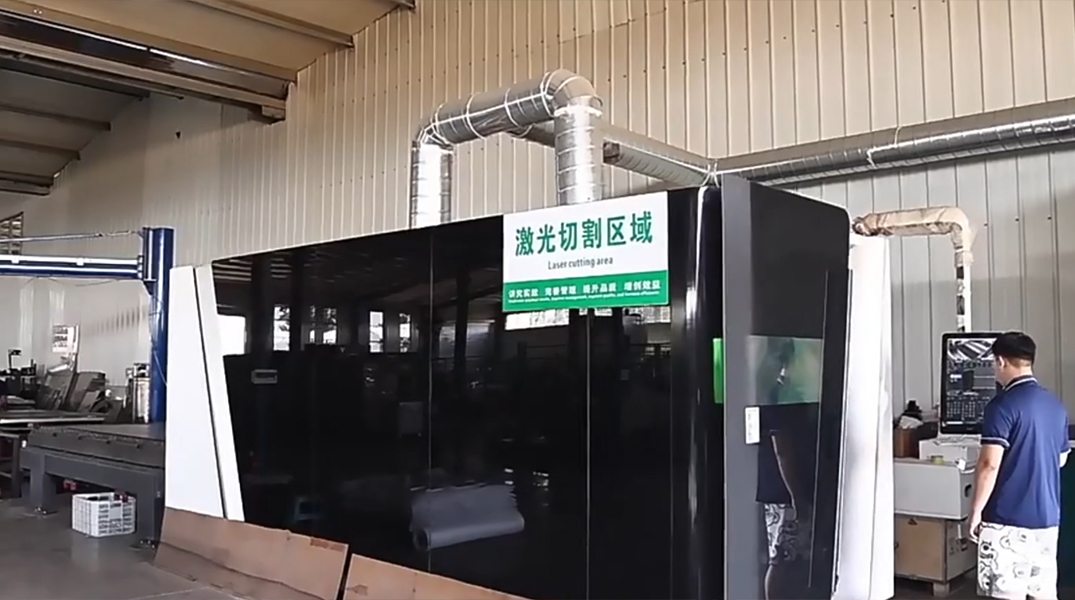

During the audit, the customers conducted a comprehensive inspection of Zongheng International's production lines, with a focus on observing the operation of high-power fiber laser cutting machines, the mold change efficiency of multi-station turret punch presses, as well as the precision control and surface protection measures in the bending process. The company's quality department also demonstrated the on-site inspection process of key dimensions using a coordinate measuring machine (CMM), and presented the complete ISO 9001 quality management documents and raw material traceability system.

To show respect for its international partners and sincerity in cooperation, the national flags of China and India were hung on the factory campus, creating a solemn and friendly atmosphere. Technical personnel from both sides held multiple closed-door discussions on topics including sheet metal design optimization, material utilization improvement, welding sealing standards, and delivery cycle guarantee. The Indian customers highly praised DEEPLINK's flexible production capabilities, rigorous process control, and continuous improvement mechanism. They also confirmed the cooperative order for the first batch of precision cabinet products on the spot and signed a three-year strategic supply framework agreement.

A relevant person in charge of DEEPLINK stated that the successful trip to the Canton Fair and the signing of the agreement with the Indian customer mark an important milestone in the company's internationalization strategy. "In the future, we will continue to focus on the fields of sheet metal processing and metal structural part manufacturing. Relying on advanced capabilities in laser cutting, metal stamping, welding, and surface treatment, we will provide global customers with more stable, efficient, and customized supply chain solutions, and continuously promote mutually beneficial industrial collaboration."