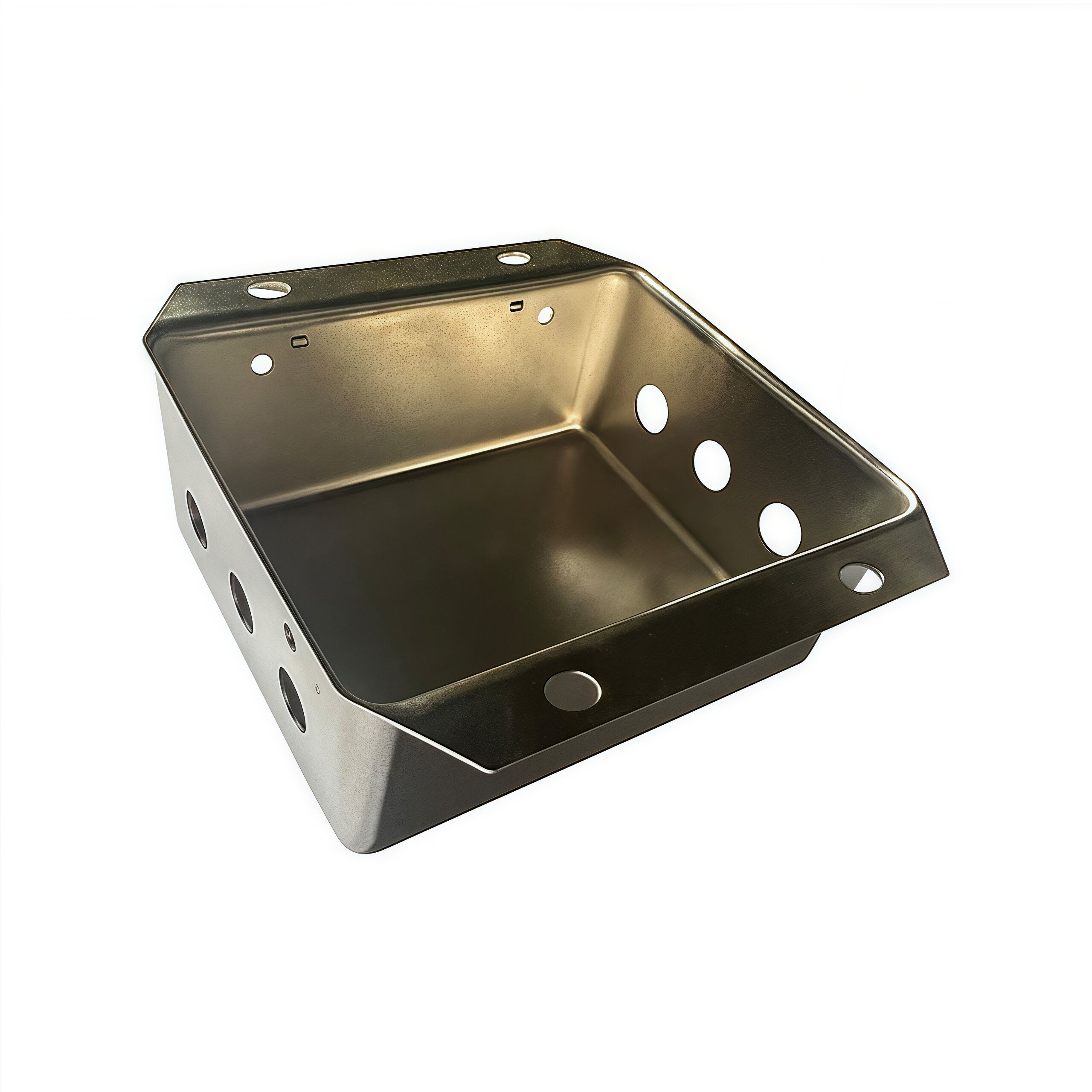

Súčiastky z tenkostenných hlbokotažných plechov sú neoddeliteľnou súčasťou rôznych vysokorozvíjajúcich výrobných aplikácií a vyznávajú sa ľahkou konštrukciou s vysokou pevnosťou. Tieto súčiastky sa vyrábajú prostredníctvom špeciálneho procesu tvárnenia kovov, pri ktorom sa plech tvaruje do požadovaného tvaru pomocou nástroja. Táto technika nielenže minimalizuje odpad materiálu, ale zároveň umožňuje vytvárať zložité dizajny, ktoré je nemožné alebo veľmi ťažko dosiahnuť tradičnými obrábacími metódami.

Spoločnosť Cangzhou Deeplink International Supply Chain využíva pokročilé technológie a odborné vedomosti na výrobu tenkostenných tažených dielov, ktoré spĺňajú najvyššie štandardy kvality. Naše produkty sa široko používajú v odvetviach, ako sú automobilový priemysel, letecký priemysel a elektronika, kde sú na prvom mieste presnosť a spoľahlivosť. Vďaka výberu našich tenkostenných tažených dielov môžu zákazníci počítať s vyšším výkonom produktov a zníženou hmotnosťou, čo prispieva k celkovej efektívnosti ich výrobných procesov.

Naša angažovanosť pri uspokojovaní zákazníkov nás núti neustále inovovať a zlepňovať našu ponuku. Pracujeme úzko so zákazníkmi, aby sme porozumeli ich špecifickým požiadavkám a poskytli im riešenia mierené presne na mieru ich cieľom. Či už potrebujete štandardné komponenty alebo vlastné návrhy, náš tím je pripravený doručiť tenkostenné tažené diely najvyššej kvality, ktoré prekračujú očakávania.