Material Selection and Thickness Considerations

Common Materials in Custom Sheet Metal Fabrication

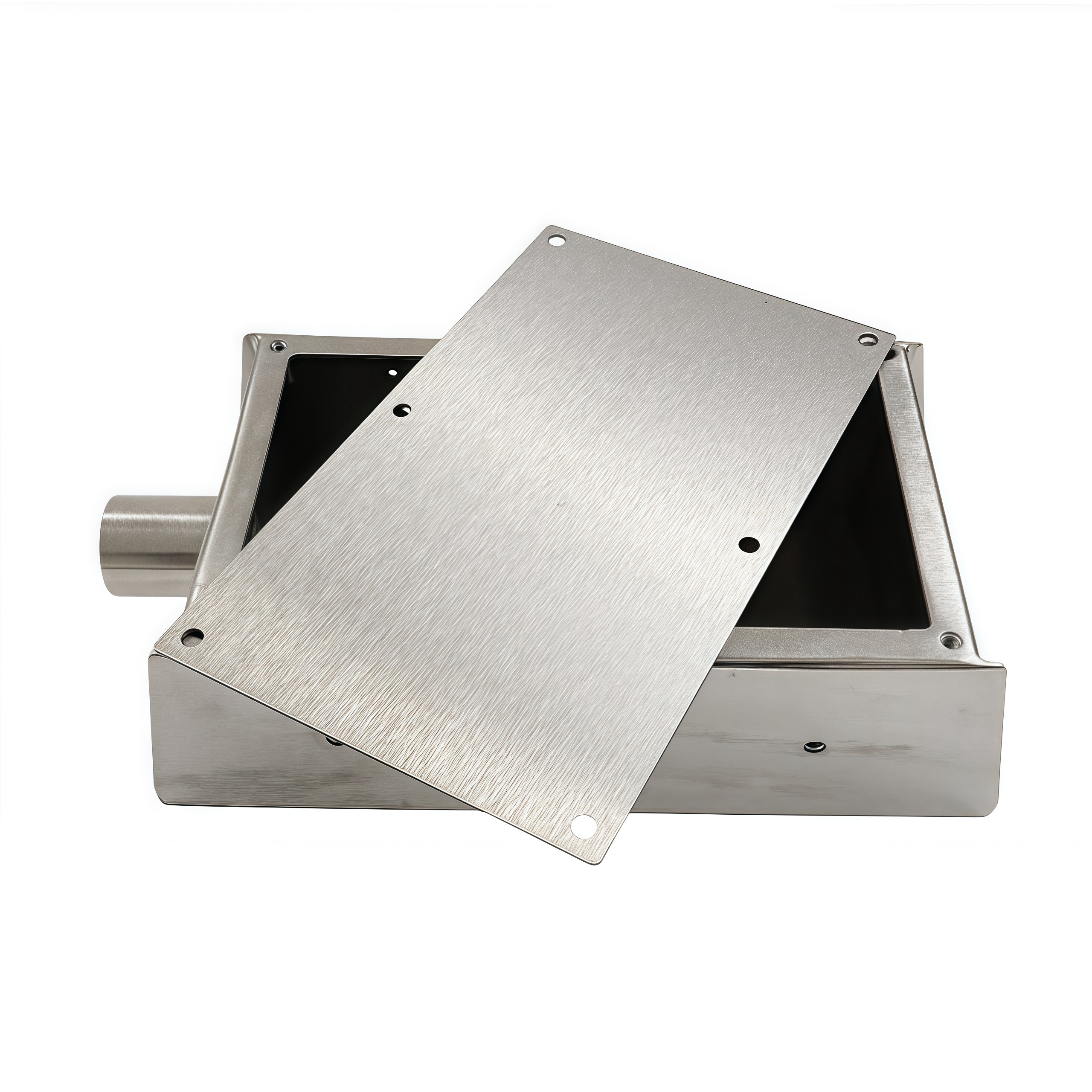

When working with custom sheet metal fabrication, knowing which materials work best really matters for getting good results. The most common options out there are stainless steel, aluminum, copper, and brass. Stainless steel stands out because it resists corrosion so well and stays strong even when exposed to harsh chemicals. That's why we see it all over food processing plants and hospitals where cleanliness is key. Aluminum has this great combination of strength without too much weight, which is why car makers and aircraft manufacturers love it for parts that need to be light but still tough. Plus, aluminum conducts heat pretty well, so it shows up a lot in those cooling fins behind computer processors. Copper is basically nature's best at conducting both electricity and heat, which explains why it dominates in electronics manufacturing and heating ventilation systems. Brass gives decent protection against rust while looking nice too, making it popular for things like bathroom fixtures or other decorative hardware around buildings. Looking at what's happening in the market right now, companies tend to pick their metals based on what they actually need for each job rather than just going with whatever's available. This focus on matching material properties to specific requirements has become a big deal in modern metal fabrication shops.

Impact of Gauge and Thickness on Design

Sheet metal thickness, often referred to as gauge, really matters in design work because it affects how strong, heavy, and heat resistant the material will be. Getting the right gauge means having enough strength without making things too heavy, something critical in industries like planes and cars where every ounce counts toward performance. For instance, logistics companies need just the right gauge to keep cargo safe during transport. Lighter gauges cut down on weight and bend easier during manufacturing, whereas thicker ones offer better strength but come with heavier materials and tougher fabrication challenges. When picking a gauge, manufacturers look at what exactly they need for their project plus follow industry guidelines. Most auto makers stick with gauges ranging from 18 to 24 since these numbers strike a good balance between being able to shape the metal and maintaining necessary structural integrity.

Coatings and Surface Treatments for Durability

Surface coatings and treatments play a major role in making sheet metal parts last longer and perform better under various conditions. When picking the right treatment, manufacturers need to consider how tough the environment will be and what kind of contact the part will have with other materials. Three popular options stand out in the industry: powder coating, anodizing, and galvanizing. Powder coating does wonders for fighting corrosion while giving components a nice finish with lots of color choices available. For aluminum parts, anodizing works great because it boosts resistance to corrosion and allows for some pretty cool dye colors that can really make products stand out visually. Steel parts often get galvanized by applying a layer of zinc to stop rust from forming. We've seen this work well in practice too. A recent look at outdoor HVAC systems found that those with powder coating lasted about five extra years compared to untreated ones. Choosing the correct treatment isn't just about looks either it directly affects how long parts will function properly across different environments, which is why experienced fabricators always spend time evaluating their options carefully before production begins.

Design Principles for Precision Sheet Metal

Bend Allowance and K-Factor Calculations

Getting a handle on bend allowance and what the K-Factor means makes all the difference when designing sheet metal components. The bend allowance basically tells us how much extra material we need to account for when making bends so they come out right. Then there's this thing called the K-Factor, which helps figure out where exactly the neutral axis sits within the material relative to its thickness. Without knowing these numbers, parts just won't measure up properly after fabrication. For engineers working with metal sheets day in and day out, accurate calculations based on these parameters ensure everything fits together as intended without costly rework down the line.

Calculating bend allowance involves using formulas that take into account things like what kind of material we're working with and how thick it is. Take this formula for example BA equals pi divided by 180 multiplied by the bend angle times inside radius plus K factor times thickness. Getting these numbers right matters a lot because when manufacturers produce machined parts, they need those measurements spot on to hit the required tolerances. Without proper bend allowances, parts just won't fit together properly in the final assembly, leading to all sorts of problems down the line.

Optimizing Hole Placement and Bend Radii

Strategic hole placement and appropriate bend radii are key components in maintaining the structural integrity of sheet metal designs. Optimal placement of holes enhances both the functionality and resilience of fabricated parts. Suboptimal hole configurations can lead to weakened structures that may fail under pressure.

When designing parts for fabrication, it makes sense to position holes away from areas where bending will occur. This simple rule can save headaches later when trying to shape materials without causing unwanted distortions. Most manufacturing specs recommend certain bend radii depending on how thick the material is and what kind of metal we're working with. Take sheet metal for instance. Research indicates that matching the bend radius to the actual thickness of the metal goes a long way toward avoiding those pesky stress points that lead to cracks down the road. What does this mean practically? Smoother bends, less scrap metal piling up on the shop floor, and ultimately faster turnaround times for production runs. Many shops have learned this lesson the hard way after dealing with warped components and costly rework.

Tolerances for Machining Parts Manufacturers

Getting the right tolerances set properly makes all the difference when it comes to putting sheet metal parts together and getting them to work right. Basically, tolerances are those little margins that tell us how much a part can vary in size before it stops fitting with other components. Without these limits, everything just falls apart literally and figuratively. Most shops that cut and shape metal depend on clear tolerance specifications because they know from experience what happens when things aren't precise enough. A few thousandths here or there might not seem like much, but in manufacturing, those small differences mean the difference between a product that works flawlessly and one that ends up scrapped.

In manufacturing, different kinds of tolerances get used based on what exactly needs to be made. Things like geometric tolerances and dimensional tolerances come into play depending on the job at hand. Most manufacturers follow guidelines set by groups such as ISO and ASME when it comes to what counts as acceptable tolerance levels. These standards help keep product quality consistent across batches. Take ISO 2768 for example. This standard gives manufacturers a way to specify general tolerances for straight lines and angles. Without these kinds of specifications, getting precise results in custom sheet metal work would be practically impossible. The framework helps ensure parts fit together properly even when slight variations occur during production.

Fabrication Processes and Tooling Requirements

Bending Dies for Sheet Metal: Setup and Best Practices

In sheet metal work, bending dies make all the difference when it comes to getting those accurate bends just right. They're basically what shapes flat metal sheets into whatever angles and forms we need for different projects. When setting things up, pick the correct die according to both the metal's thickness and how tight or wide the final bend needs to be. Getting the die properly aligned and locked down in the press brake is really important if we want consistent results across multiple pieces. Most experienced fabricators will tell you to check their dies regularly for signs of wear because even small cracks or deformations can throw off entire batches. And don't forget to tweak settings carefully based on the actual material being used since steel might behave differently from aluminum under pressure, affecting how accurately our machines create those bends.

Sheet metal workers regularly talk about how following certain practices makes a real difference in their work. Take John at MetalCraft for example he noticed his shop waste dropped by almost 30% when they started being more careful about which dies they used. Keeping dies clean and properly lubricated pays off in several ways. First, it means those expensive tools last longer before needing replacement. Second, it helps ensure each time the press runs, the parts come out looking good without all those frustrating defects that slow down production. This matters a lot in industries where precision counts, like automotive manufacturing or aerospace components.

Laser Cutting vs. Plasma Cutting Techniques

Looking at different fabrication methods, anyone serious about metalwork needs to weigh up laser cutting against plasma cutting since they each bring something special to the table. Laser tech stands out because of how precise it can be, making those really detailed cuts while keeping the kerf width super narrow. Great stuff for jobs where every millimeter matters. Plasma cutting on the other hand gets the job done faster and costs less when dealing with thick sheets of metal. The downside? The cut ends up being wider than what lasers deliver. Still, for certain applications where speed counts more than absolute precision, plasma remains a solid choice.

When picking between these methods, manufacturers should really think about what works best for them specifically. Things such as how thick the materials are, how detailed the projects need to be, plus money matters all play into this choice. Looking at recent data from the market, there seems to be more interest in laser cutting among businesses that need exact measurements. At the same time, plasma cutting still holds its ground in shops where getting things done fast and keeping costs down matters most. The industry is clearly splitting along these lines depending on whether precision or speed takes priority.

Welding Methods and Post-Processing Finishes

Sheet metal fabrication relies heavily on several key welding techniques including MIG, TIG, and spot welding, all of which work best for different situations. Most shops go with MIG when they need something quick and straightforward, particularly good for working with thicker materials. TIG welding gets the nod from professionals who want fine details and clean finishes, making it ideal for delicate jobs on thinner metals. Then there's spot welding that really shines when dealing with thin sheets that don't require full length welds. Think automotive body panels or appliance parts where just a few strategic points will do the trick.

Cleaning up after welding isn't just about looks it actually makes a big difference for how well the joints work too. When manufacturers take time to remove burrs, clean surfaces properly, and address those ugly weld seams, they're doing much more than making things look nice. The metal needs to be safe to handle without sharp bits sticking out, plus all that residue has to go so nothing interferes with performance later on. Most shops follow ISO guidelines which specify exactly what counts as acceptable finish quality after welding. These standards cover everything from how smooth surfaces should be to whether there are any hidden weaknesses in the joint structure. Meeting these requirements isn't optional for serious fabricators who want their products to last and perform reliably over time.

Quality Control in Sheet Metal Projects

Precision Measurement Tools for Industry Standards

Getting accurate measurements is absolutely key to making sure quality stays consistent throughout sheet metal fabrication work. The shop floor relies on basic but crucial instruments like calipers, micrometers, and various types of gauges to keep everything within those tight tolerances needed for good parts. Without these measuring devices, components just won't fit right when assembled later on. Most shops follow ISO 9001 guidelines because they help establish proper quality control procedures from start to finish. This standard basically creates a roadmap for documenting every step properly so nothing gets missed. Many experienced fabricators swear by digital calipers now instead of old fashioned analog ones, while some advanced operations have even adopted laser measurement tech. These modern tools really make a difference in keeping up with the ever increasing demands for precision in manufacturing today.

Managing Stress Concentrations in Critical Components

Getting a handle on stress concentrations matters a lot when working with sheet metal parts during design and manufacturing. Basically, stress concentrations are spots in materials where stress builds up way more than in the surrounding area, which usually means trouble down the road for those components. Sheet metal fabrication brings this issue front and center because all those complex shapes and detailed features create perfect conditions for stress risers to form. There are several ways to tackle this problem though. One common approach involves changing geometry so there are smooth transitions instead of those sharp corners everyone hates. Choosing materials with better fatigue resistance also helps cut down on failures. Industry research backs this up pretty strongly actually. Components made without considering stress concentrations just don't last as long before breaking. The numbers speak for themselves really. When manufacturers take these factors seriously, they end up with sheet metal products that stand the test of time while still meeting all necessary safety standards and performance expectations.