Precision Metal Stamping Process: The Perfect Integration of Technological Innovation and Quality Assurance

I. In-depth Analysis of Metal Stamping Process

Metal stamping is a manufacturing process that applies pressure to metal sheets placed in dies to cause plastic deformation or separation, thereby obtaining parts of the required shape. The core value of this process lies in its high efficiency, high precision, and excellent cost control capabilities.

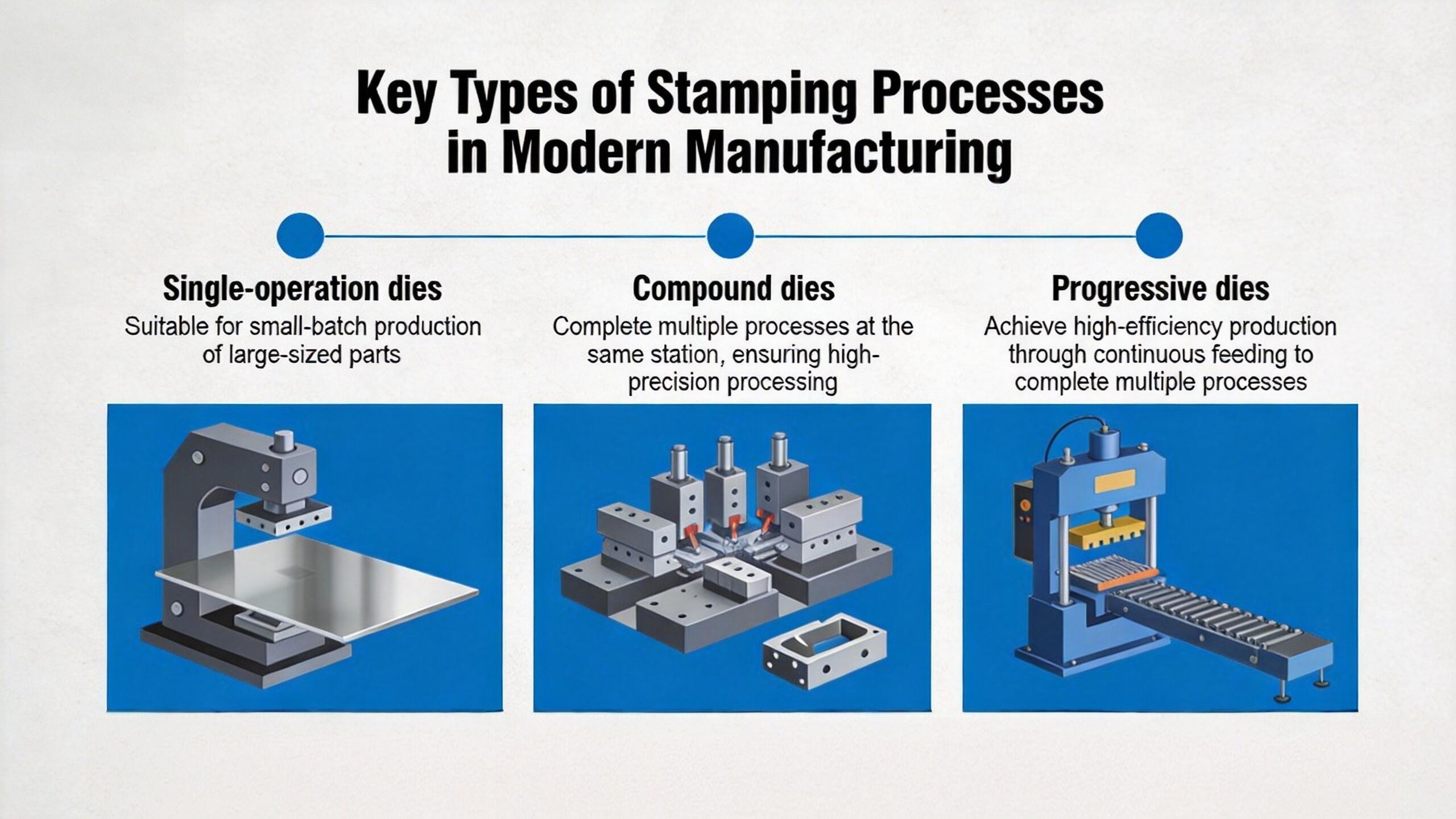

In modern manufacturing, stamping processes are mainly divided into the following key types:

- Single-operation dies: Suitable for small-batch production of large-sized parts

- Compound dies: Complete multiple processes at the same station to ensure high-precision processing

- Progressive dies: Achieve high-efficiency production by completing multiple processes through continuous feeding

Each process type has its unique application scenarios and advantages, and the selection needs to be based on specific product requirements.

II. Key Technical Elements of Stamping Process

1. Material Selection and Treatment

Selecting the appropriate metal material according to product requirements is crucial for the success of stamping projects. We specialize in processing a variety of materials, each with unique advantages:

- Carbon steel: Excellent mechanical strength and high cost performance. Suitable for structural parts and industrial components.

- SPCC (Cold-rolled steel): Good surface quality and excellent formability. Ideal for precision parts and consumer products.

- SGCC (Galvanized steel): Equipped with a galvanized layer for corrosion resistance and good formability. Suitable for outdoor applications and automotive parts.

- Stainless steel: Outstanding corrosion resistance and strong durability. Suitable for medical, food processing, and marine applications.

- Aluminum alloy: Lightweight with excellent electrical and thermal conductivity. Suitable for weight-sensitive application scenarios.

- Copper: Excellent electrical and thermal conductivity, combined with natural antibacterial properties. It is an ideal choice for electronic components and heat exchangers.

Our material pre-treatment process includes leveling, cleaning, and surface treatment to ensure the materials are in optimal performance state before production. Each material undergoes strict quality verification to guarantee the stable and reliable performance of the final stamping products.

2. Mold Design and Manufacturing

Molds are the core of the stamping process. Our mold design team has the following advantages:

- Use advanced CAD/CAE software for mold design

- Predict and solve potential problems through finite element analysis

- Adopt precision processing equipment to ensure mold accuracy

- Establish a sound mold maintenance and management system

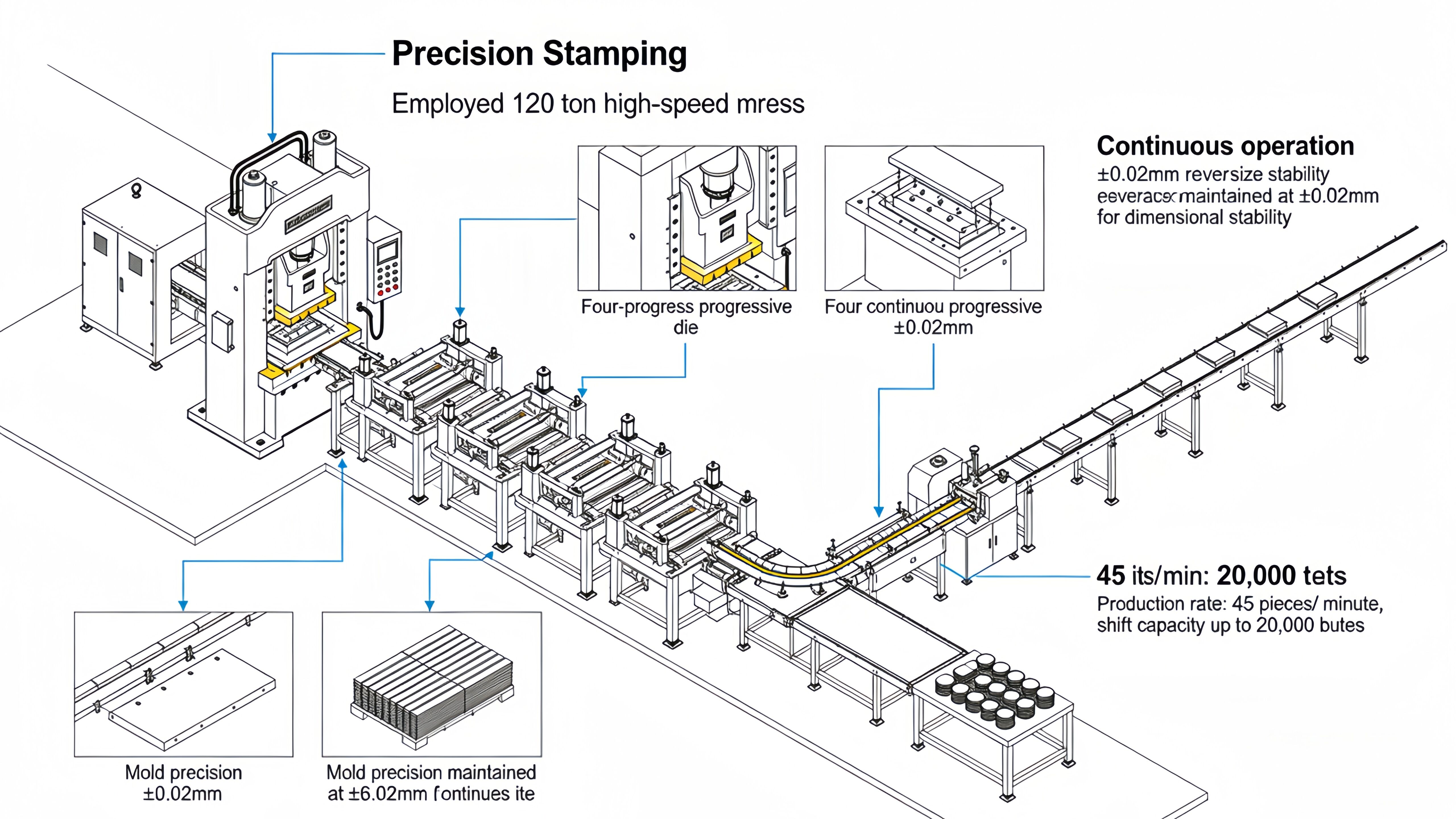

III. Detailed Explanation of Deeplink's Stamping Manufacturing Advantages

1. Advanced Equipment Guarantee

We have 6 automated production lines with an automation level of 80%. The main equipment includes:

- High-speed precision punch presses: Maximum speed up to 120 strokes per minute

- Multi-station transfer mold stamping equipment: Realize one-time forming of complex parts

- Precision progressive die production lines: Suitable for mass production needs

These equipment, combined with advanced control systems, ensure the stability and accuracy of the production process.

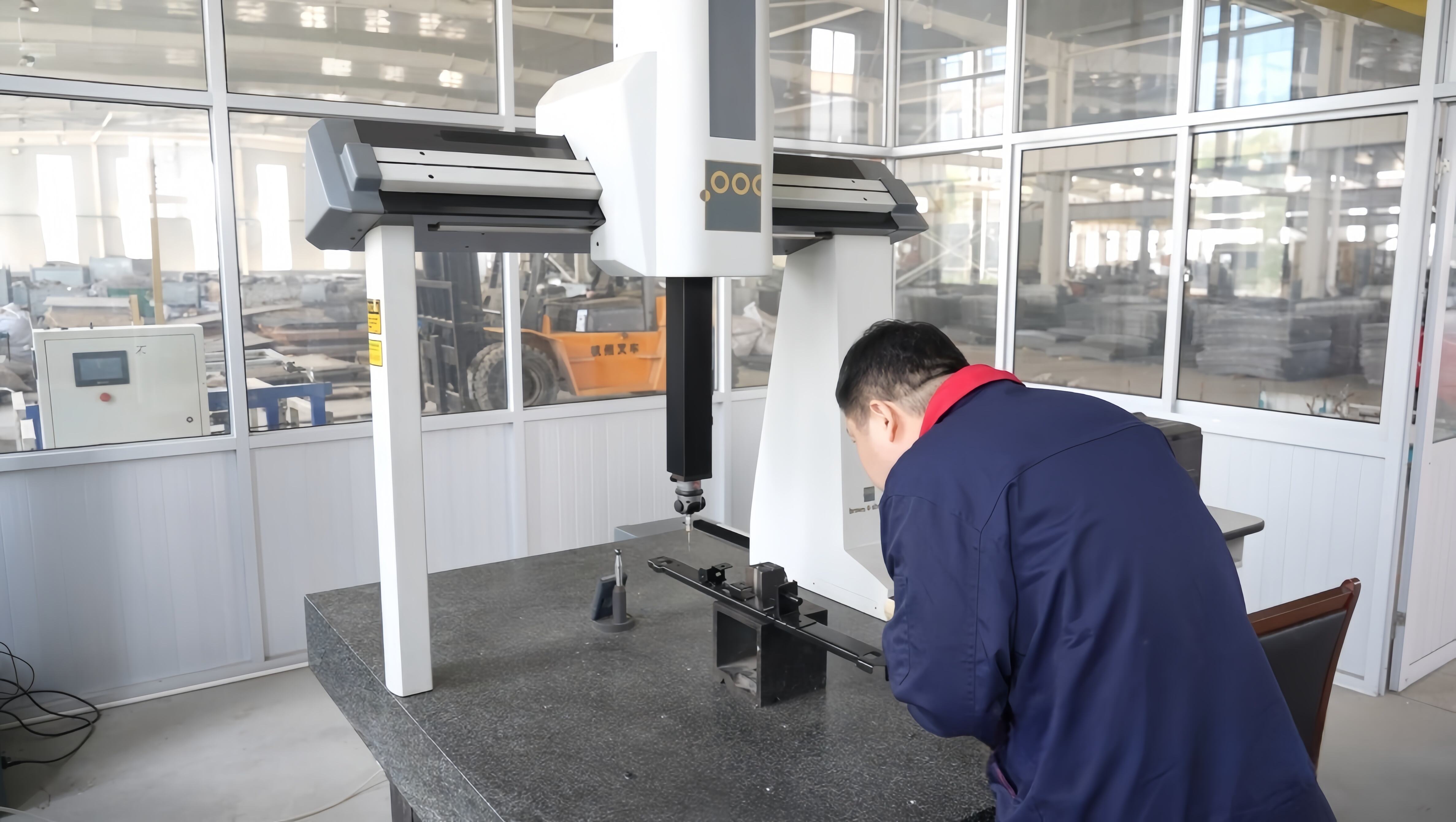

2. Comprehensive Quality Management System

Our quality control system covers every link from raw materials to finished products:

- Incoming inspection of raw materials: Ensure material performance meets requirements

- Production process monitoring: Real-time monitoring of key process parameters

- 100% inspection of finished products: Use precision equipment such as coordinate measuring machines

- Regular third-party certification: Pass authoritative certifications such as SGS and ISO

IV. Process Innovation and Technological Breakthroughs

1. Precision Stamping Technology

Through technological innovation, we have achieved remarkable results in the following aspects:

- Micron-level precision control

- Thin-sheet stamping technology

- Processing of difficult-to-machine materials

2. Automation and Intelligence

We actively promote the transformation to intelligent manufacturing:

- Introduce robotic automated loading and unloading systems

- Implement a Manufacturing Execution System (MES) for full-process management

- Establish a digital quality traceability system

V. Comprehensive Service Support System

1. Technical Consultation and Solution Design

Our engineering team provides comprehensive technical support:

- DFM (Design for Manufacturability) analysis

- Customized process solutions

- Cost optimization suggestions

- Rapid sample making service

2. After-sales Guarantee

We commit to:

- Respond to customer inquiries within 24 hours

- Provide comprehensive technical support

- Ensure on-time delivery

Conclusion

As a professional manufacturer in the metal processing field, Cangzhou Deeplink has always adhered to technological innovation as the driving force and quality assurance as the foundation to provide customers with the highest quality products and services. No matter what challenges your project faces, we can provide professional solutions.

Welcome to obtain more technical data and customized solutions through the contact information on our website. Our professional team is ready to provide you with support and jointly promote the successful implementation of your project.

Table of Contents

- Precision Metal Stamping Process: The Perfect Integration of Technological Innovation and Quality Assurance

- I. In-depth Analysis of Metal Stamping Process

- II. Key Technical Elements of Stamping Process

- III. Detailed Explanation of Deeplink's Stamping Manufacturing Advantages

- IV. Process Innovation and Technological Breakthroughs

- V. Comprehensive Service Support System

- Conclusion