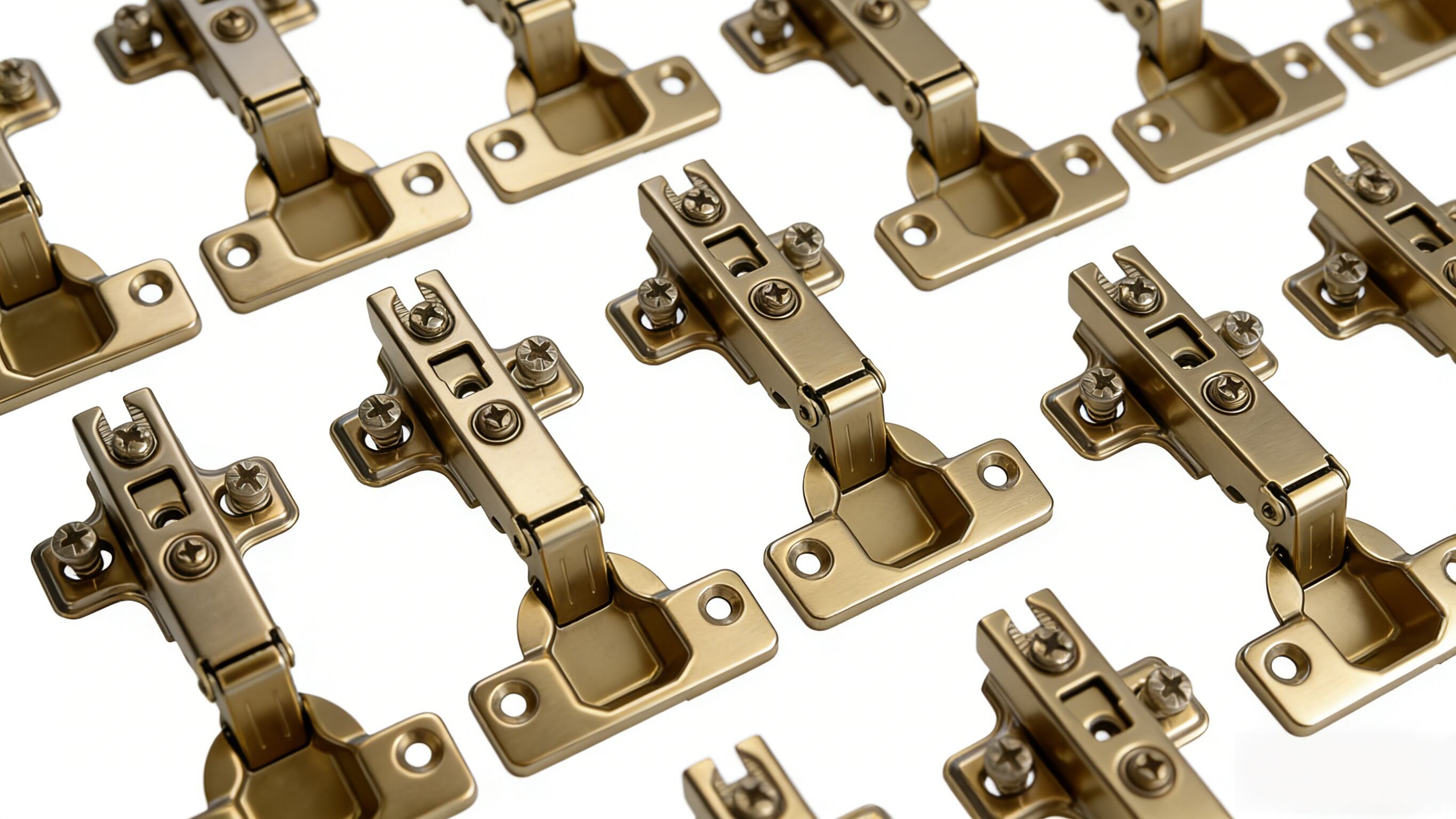

In the furniture hardware industry, hinge quality is the cornerstone of both user experience and longevity. Recently, we partnered with a client deeply experienced in the global furniture market to mass-produce cold-rolled steel hinges for cabinets and wardrobes. The mandate was clear: deliver products that excel in smooth operation, stable load-bearing, and durable rust protection.

Rising to the challenge, DEEPLINK utilized its comprehensive metal processing expertise. Starting with premium SPCC cold-rolled steel, we applied stringent precision techniques to solve key manufacturing hurdles. The result? A final product that earned high praise from the client. Here is the full case study of this project.

I. Core Requirements & Material Selection

The client’s demands were specific and stringent:First, the hinges needed to be machined from cold-rolled steel to capitalize on its superior formability and strength, delivering a robust 8kg load capacity per unit. Second, the design required a 105° opening angle paired with a quiet, soft-close mechanism, backed by a durability rating of over 50,000 cycles. Finally, the surface finish demanded exceptional rust resistance to withstand the damp conditions of kitchens and bathrooms.

For the raw material, we chose premium SPCC cold-rolled steel sheets (2.5mm thick). Renowned for its balanced yield strength and elongation, this material excels in complex stamping operations. We fortified quality at the source through rigorous inspections, ensuring zero surface defects, no impurities, and consistent chemical composition.

II. Comprehensive Manufacturing Process & Technology

Our approach to manufacturing these cold-rolled steel hinges utilized a seamless workflow: "Stamping Forming + Precision Assembly + Eco-Friendly Surface Treatment." By tightly linking each stage, we leveraged technical refinements to guarantee superior accuracy and performance.

1. Preparation: Decoiling, Leveling & Strategic Planning

The process began with the decoiling and leveling of cold-rolled steel coils. Advanced leveling machinery removed internal stress from the material, achieving a flatness tolerance of ≤0.1mm to prevent warping during manufacturing. Furthermore, our technical team conducted a thorough analysis of the client's blueprints to define critical hinge dimensions. We designed a specialized multi-position progressive die stamping solution that combined blanking, punching, and pre-bending into a single, efficient sequence, significantly boosting both productivity and precision.

2. The Core Process: Multi-Station Stamping

At the heart of hinge production lies the stamping process. We deployed a 125-ton high-precision press with a custom multi-station progressive die to execute a seamless sequence of operations:

- ① Blanking & Punching: Simultaneously shaping the main body, mounting holes, and axle holes in one stroke for perfect blank formation.

- ② Bending: Transforming the flat sheet into the essential "L-shape." Our dies ensure precise angle control to eliminate any springback issues.

- ③ Roll Forming (The Critical Step): This step dictates the hinge's smoothness. We use a progressive rolling technique across 3 stations to gradually form the circular bushing. This method guarantees perfect roundness and a burr-free, polished surface.

- ④ Sizing & Finishing: We refine the dimensions to eliminate any residual springback. Finally, automated deburring ensures the edges are smooth and safe, preventing any risk of scratches during installation or use.

3. Precision Assembly: Integrating the Soft-Close Mechanism

Delivering on the promise of silent operation required the integration of custom hydraulic dampers. Our assembly process prioritized the perfect fit between the damper and the hinge body. Using automated riveting machines, we secured the dampers, springs, and shafts with pinpoint accuracy. Each hinge then underwent rigorous testing—both automated and manual—to validate its performance. We ensured a smooth 105° opening angle, consistent soft-close damping, and zero impact noise. Only hinges that met our strict cycle test standards were approved for the final finish.

4. Surface Finish: Eco-Friendly Plating for Lasting Durability

For superior rust protection, we implemented a premium eco-friendly finishing process: "Pickling & Degreasing + Nickel Plating + Passivation." Starting with a thorough pickling to remove oils and oxides, we applied a precise 8-10μm nickel plating for a flawless, dense finish. A final passivation treatment locked in the corrosion resistance. Committed to sustainability, our process meets international environmental standards with compliant VOCs emissions. The result is a finish with exceptional adhesion that withstands over 48 hours of salt spray testing, ensuring long-lasting performance even in damp kitchen or bathroom environments.

5. Quality Control: Rigorous Testing & Zero-Defect Assurance

Quality control is embedded in every step of our process. Before shipment, every batch undergoes a battery of tests:

- ① Precision Measurement: We utilize 2D optical measuring systems to scan critical dimensions, guaranteeing they align perfectly with the client’s blueprints.

- ② Performance Validation: Hinges are put through their paces with rigorous cycle testing, load-bearing trials, and buffer mechanism evaluations.

- ③ Finish Inspection: We meticulously examine the surface for a uniform plating finish, ensuring zero scratches or flaking.

- ④ Final Audit: A strict 10% random sampling protocol is enforced before packaging. Our commitment is absolute: only perfect products reach our clients.

III. Project Success & Client Endorsement

The project successfully delivered 50,000 cold-rolled steel hinges, all of which passed rigorous acceptance checks with flying colors. In fact, key performance metrics outperformed standard industry benchmarks. Following a rigorous six-month trial, the hinges proved their superior rust resistance with a flawless quality record. This success has solidified a long-term partnership; the client now relies on us for a continuous supply of various hardware components.

IV. DEEPLINK: Our Core Strengths

The seamless execution of this project highlights the four pillars of DEEPLINK's expertise:

- Process Excellence: Our mastery of multi-station stamping, precision rolling, and eco-friendly finishing allows us to cover the entire production lifecycle of precision hardware like hinges. We maintain tight control over critical tolerances to ensure unwavering performance.

- Advanced Equipment: Our state-of-the-art machinery park is designed for scale and accuracy. We deliver high-volume production without compromising on consistency or efficiency.

- Technical Prowess: Our expert R&D team thrives on solving complex manufacturing challenges. We specialize in custom tooling and tailored solutions, adapting our expertise to fit your unique hardware needs.

- Uncompromising Quality: Quality is built into every stage—from raw material to finished product. Our rigorous QC protocols and eco-conscious manufacturing ensure compliance and perfection in every piece.

At DEEPLINK, we believe in "Precision Processing, Quality Supreme." Backed by our full-chain capabilities, we deliver custom metal solutions to the world. From precision hardware to structural and irregular components, we combine technical skill with meticulous care to ensure delivery excellence. Partner with DEEPLINK—your reliable ally in metal manufacturing.