New Energy Storage Cabinet Customization Case: DEEPLINK Tackles Three Core Challenges

When a new energy technology firm approached DEEPLINK, its core requirements were clear-cut: customize metal cabinets for a next-generation energy storage system, meeting three non-negotiable criteria—"high-precision assembly, superior corrosion resistance, and mass delivery in 30 days". The cabinets must accommodate the dense installation of energy storage battery modules while withstanding harsh outdoor operating conditions. This demand not only tested the precision of manufacturing processes but also imposed extremely high standards for full-industry-chain collaboration.

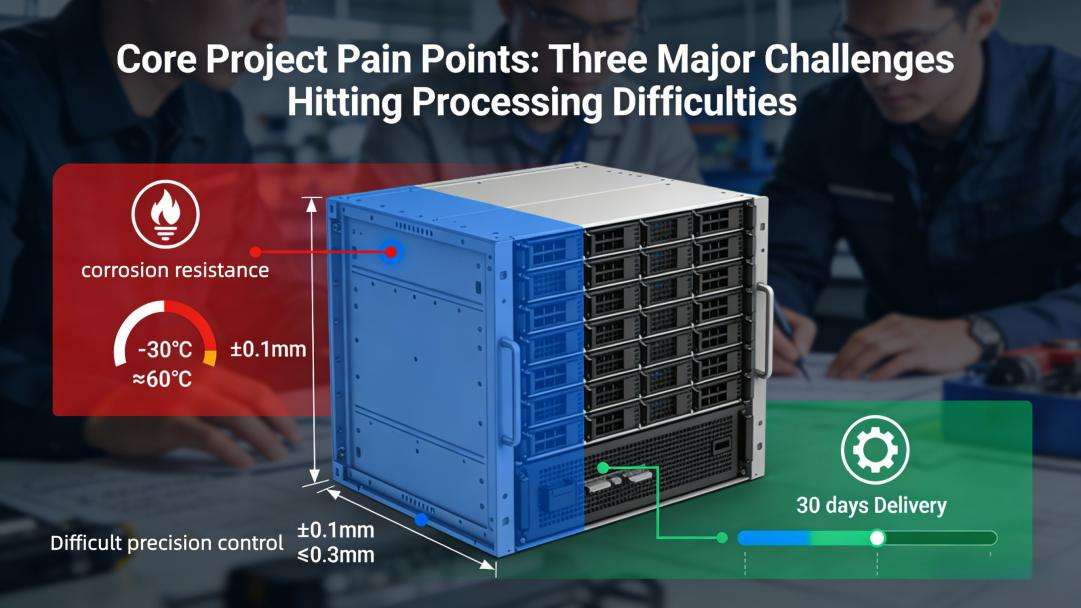

Core Project Pain Points: Three Critical Manufacturing Challenges

Stringent precision control: The cabinet required 12 reserved mounting positions for battery modules, with a hole diameter tolerance of ±0.1mm and a frame verticality deviation of ≤0.3mm. Traditional manufacturing processes are susceptible to cumulative errors, leading to module assembly jams;

High corrosion resistance demands: Intended for outdoor energy storage power stations, the product must pass a 48-hour salt spray test and endure temperature cycles from -30℃ to 60℃ after surface treatment to prevent rust during long-term use;

Tight delivery timeline: The customer urgently needed the first batch of 500 cabinets to ensure project grid connection, with only 30 days allocated from design finalization to finished product delivery—far shorter than the industry's standard production cycle.

Customized Solutions: Process Integration + Full-Chain Collaboration to Break Bottlenecks

1. Pre-Production DFM Analysis: Optimize Structure to Reduce Manufacturing Complexity

Upon receiving the request, DEEPLINK's engineering team immediately initiated Design for Manufacturability (DFM) analysis. Integrating the 3D drawings provided by the customer, the original one-piece cabinet structure was reengineered into a "modular assembly design"—splitting it into three core components (frame, panel, and mounting bracket). This modification not only mitigates risks associated with complex structure manufacturing but also enhances assembly efficiency. Additionally, leveraging precision instruments covering over 80 testing capabilities, the team pre-established key dimension inspection standards to ensure each production step has a clear quality benchmark.

2. Core Process Combination: Balancing Precision and Corrosion Resistance

Laser Cutting Process: High-precision fiber laser cutting machines are employed for 304 stainless steel sheets, achieving a cutting accuracy of ±0.05mm—fully meeting requirements for hole diameter and sheet edge flatness. Compared to traditional plasma cutting, the process delivers burr-free, heat-deformation-free cuts, eliminating the need for additional grinding and significantly shortening the production cycle;

CNC Bending Process: High-precision CNC press brakes paired with custom bending dies are used for multi-dimensional forming of the cabinet frame. A real-time angle monitoring system controls frame verticality deviation within 0.2mm, ensuring precise alignment of module mounting positions;

Robotic Welding Process: Six-axis robotic welding is adopted for cabinet joints. Compared to manual welding, it produces uniform, full weld seams with a 60% reduction in welding deformation. Post-welding non-destructive testing (NDT) eliminates incomplete or missed welds, guaranteeing structural integrity;

Dual Surface Treatment Process: Building on the inherent superior corrosion resistance of 304 stainless steel, the process begins with electropolishing to remove surface impurities and oxide layers—enhancing surface finish while reinforcing the base material's corrosion resistance. Subsequent passivation treatment forms a dense, stable anti-corrosion passivation film (compliant with ROHS environmental standards). The final product exhibits no rust or delamination after a 48-hour salt spray test, making it fully suitable for harsh outdoor environments.

3. Automated Production + Full-Chain Collaboration: Shorten Delivery Cycles

Powered by DEEPLINK's 6 automated production lines (80% automation level), the entire manufacturing flow—from cutting, bending, and welding to surface treatment, assembly, and inspection—is seamlessly integrated. During production, a Manufacturing Execution System (MES) provides real-time production progress monitoring, while green channels are activated for critical processes. Supply chain resources are also integrated to pre-stock 304 stainless steel raw materials, avoiding material delays. Ultimately, the full-process manufacturing of 500 cabinets was completed in 30 days—2 days ahead of the customer's schedule.

Customer Feedback and Long-Term Cooperation

Post-delivery, the customer conducted comprehensive acceptance testing via a third-party authoritative inspection agency. Indicators including precision, corrosion resistance, and structural strength all met standards on the first pass, with a 100% module assembly success rate. The procurement director of the new energy technology firm stated: "DEEPLINK's process precision and delivery efficiency exceeded our expectations. Its professional capabilities in complex structure manufacturing and harsh environment adaptation reinforce our confidence in future project collaborations." Currently, the two parties have signed an annual strategic cooperation agreement, establishing DEEPLINK as its core supplier for energy storage cabinets.

Why Choose DEEPLINK?

End-to-End Service Capabilities: Deliver one-stop metal processing solutions—from drawing design and sample testing to mass production, packaging, and shipping—eliminating the need for customers to coordinate with multiple suppliers;

Rigorous Quality Certifications: Hold authoritative certifications including ISO9001/14001/45001, SGS, and ROHS. Each product undergoes 39+ QA inspection steps, ensuring full quality traceability;

Flexible Customization Response: Support OEM/ODM services with a 24/7 after-sales team to address technical inquiries promptly. Process solutions can be optimized for special operating conditions;

Automation + Precision Technology: Combine 80% automation with core processes such as laser cutting, CNC bending, and robotic welding to balance precision and efficiency.

If you have customization needs for metal chassis, cabinets, or other metal processing—whether facing challenges in precision, environmental adaptation, or delivery timelines—DEEPLINK can provide tailored solutions for you.