Metal Portable Handle Processing Case: A Journey of Quality Control from Drawing to Finished Product

I. Project Background and Core Requirements

- Customer Demand: Customize a batch of foldable and portable metal handles for their new toolboxes. The material is 304 stainless steel (corrosion-resistant and non-magnetic), requiring 180° smooth folding, mirror polishing for the surface treatment, a load-bearing capacity of ≥30kg, and passing the salt spray test (corrosion resistance grade ≥48 hours).

II. Core Processing Technology and Implementation Process

- The processing of this handle is divided into four core links, each accurately matching metal processing technology to ensure product quality and production efficiency:

1. Raw Material Pretreatment and Component Forming

- First, 304SS plates complying with the national standard GB/T 3280-2015 are selected as raw materials.

- Mounting Plate Forming: Precision stamping technology is adopted. The stainless steel plate is stamped at one time through a custom mold to complete the forming of the outer contour, screw holes, and rotating shaft mounting grooves of the mounting plate. During the stamping process, cemented carbide molds are used, combined with the precise positioning of the CNC punch press, to ensure that the hole position deviation of each batch of mounting plates meets the specifications.

-

Handle Frame Forming: An integrated process of "CNC spring coiling + setting heat treatment" is adopted. Step 1: Straighten the straightness of the stainless steel plate through a straightening machine to ensure uniform force during coiling; Step 2: Use a CNC spring coiling machine to directly coil the stainless steel plate into shape according to the preset U-shaped contour parameters, and precisely control the helix angle and tension during the coiling process; Step 3: Immediately perform spring setting heat treatment. Through precise control of temperature and time, the handle forms a stable U-shaped spring structure with reliable folding elastic reset performance. After forming, the ports are ground to remove burrs to avoid sharp edges scratching installers.

2. Assembly and Functional Debugging

- The core of the assembly link is to realize the smooth folding and stable connection of the handle. Precision riveting technology is used to fix the U-shaped frame and the rotating shaft structure of the mounting plate. First, install a stainless steel spring damper at the rotating shaft, then use a pneumatic rivet gun to accurately press the φ3mm stainless steel rivet into the reserved hole position, ensuring no looseness or deformation after riveting.

- After assembly, batch functional debugging is carried out. Each handle needs to be manually opened and closed 10 times to test the folding smoothness (no jamming, no abnormal noise), and at the same time ensure that the fitting gap with the mounting plate meets the specifications after closing.

3. Surface Treatment (Core Quality Assurance Link)

- To meet the customer's requirements for mirror effect and corrosion resistance, the surface treatment is implemented in three steps:

- Rough Polishing: Use a grinding wheel polishing machine to roughly polish the entire handle to remove surface oxide scale, stamping marks, and residual riveting burrs.

-

Fine Polishing: Focus on polishing detailed parts such as the corners of the U-shaped frame and the edges of the mounting plate to finally achieve a smooth and flawless effect.

-

Bright Finish:Finally, a polishing cloth wheel was used in combination with micron-level polishing paste to achieve a mirror-like effect.

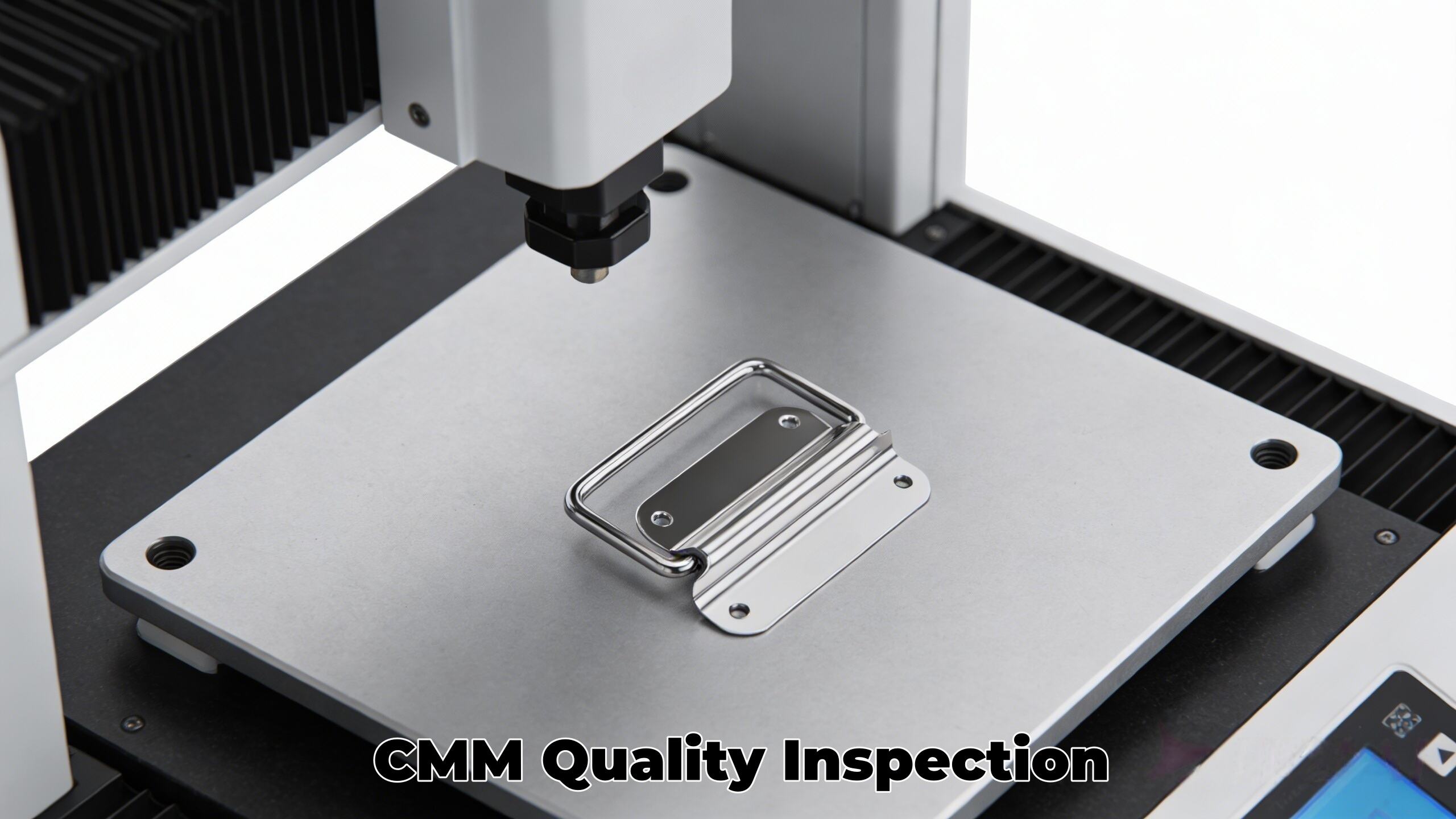

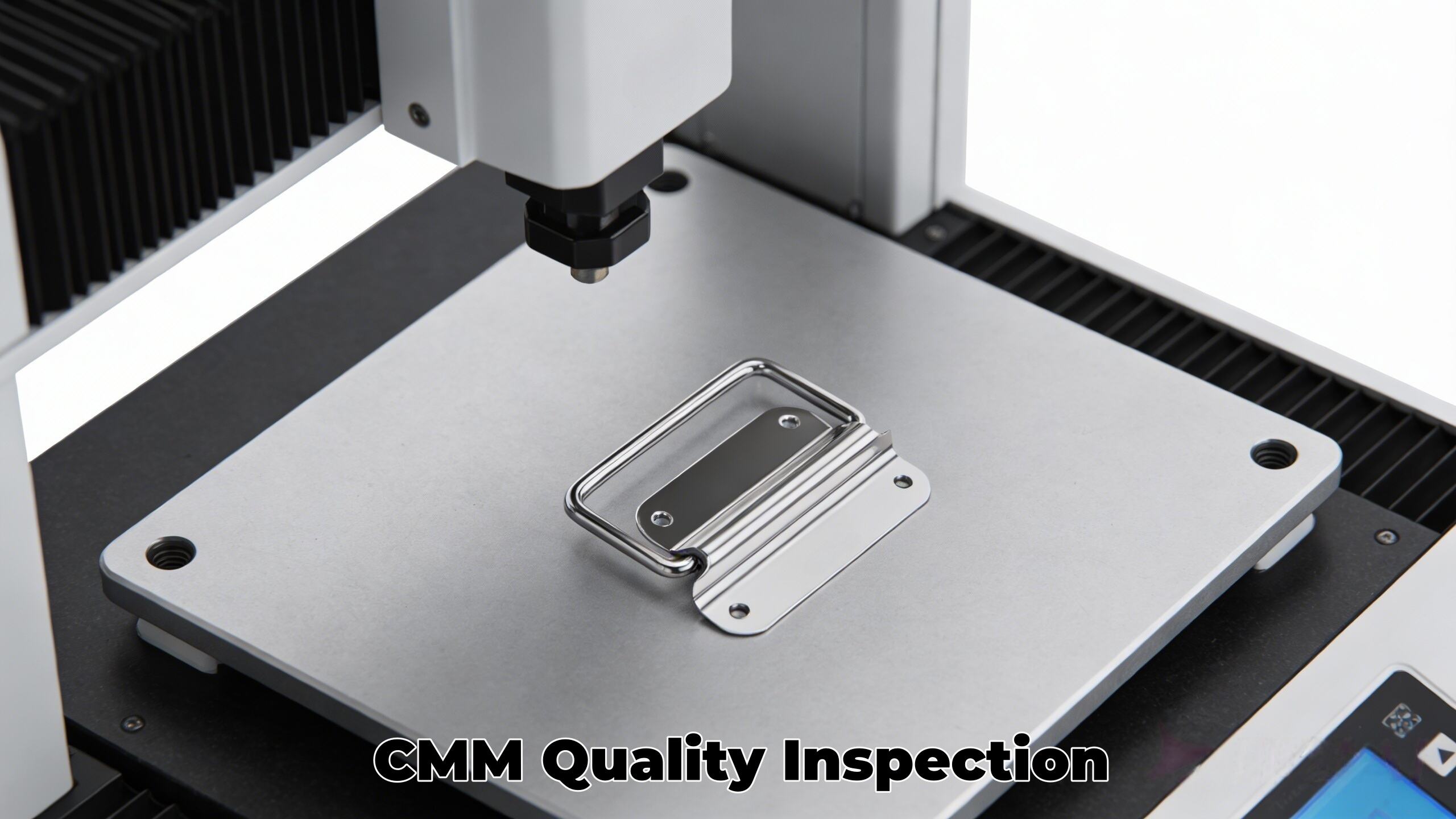

4. Finished Product Inspection and Factory Acceptance

Establish a comprehensive testing standard to ensure that each batch of products meets the requirements:

- Dimensional Accuracy Inspection: Use a coordinate measuring machine (CMM) to detect the hole positions of the mounting plate and the size of the handle frame.

- Performance Testing: Randomly select 10% of the products for load-bearing testing (load 30kg weight for 24 hours, no deformation, no fracture) and salt spray testing (48 hours in a neutral salt spray environment, no rust or coating peeling on the surface);

- Appearance Inspection: Manually inspect each product one by one for uniform surface coating, no scratches, no bubbles, and the mirror effect meets the standard.

III. Summary

In this 304 stainless steel foldable handle processing project, through the precise application of core metal processing technologies such as stamping, CNC bending, precision riveting, and electrolytic chrome plating, combined with targeted technical optimizations, the processing difficulties caused by material characteristics have been successfully solved. The finally delivered products not only meet the customer's strict requirements for precision, performance, and appearance but also won the customer's trust through the whole-process quality control. At present, this batch of handles has been mass-applied to the customer's medical equipment chassis, with good market feedback.

We have the customized processing capacity for various metal products, and can adapt to different materials (stainless steel, carbon steel, copper, brass,aluminum alloy, etc.), processes and functional requirements according to customer needs. The production is fully transparent, with controllable quality and guaranteed delivery time.