Project Background

An industrial equipment manufacturer required batch production of mounting brackets for securing automated control cabinets. These brackets need to withstand long-term use in humid industrial environments, demanding excellent structural strength and corrosion resistance. After comparing multiple suppliers, the client ultimately chose to collaborate with us.

Technical Requirements

-

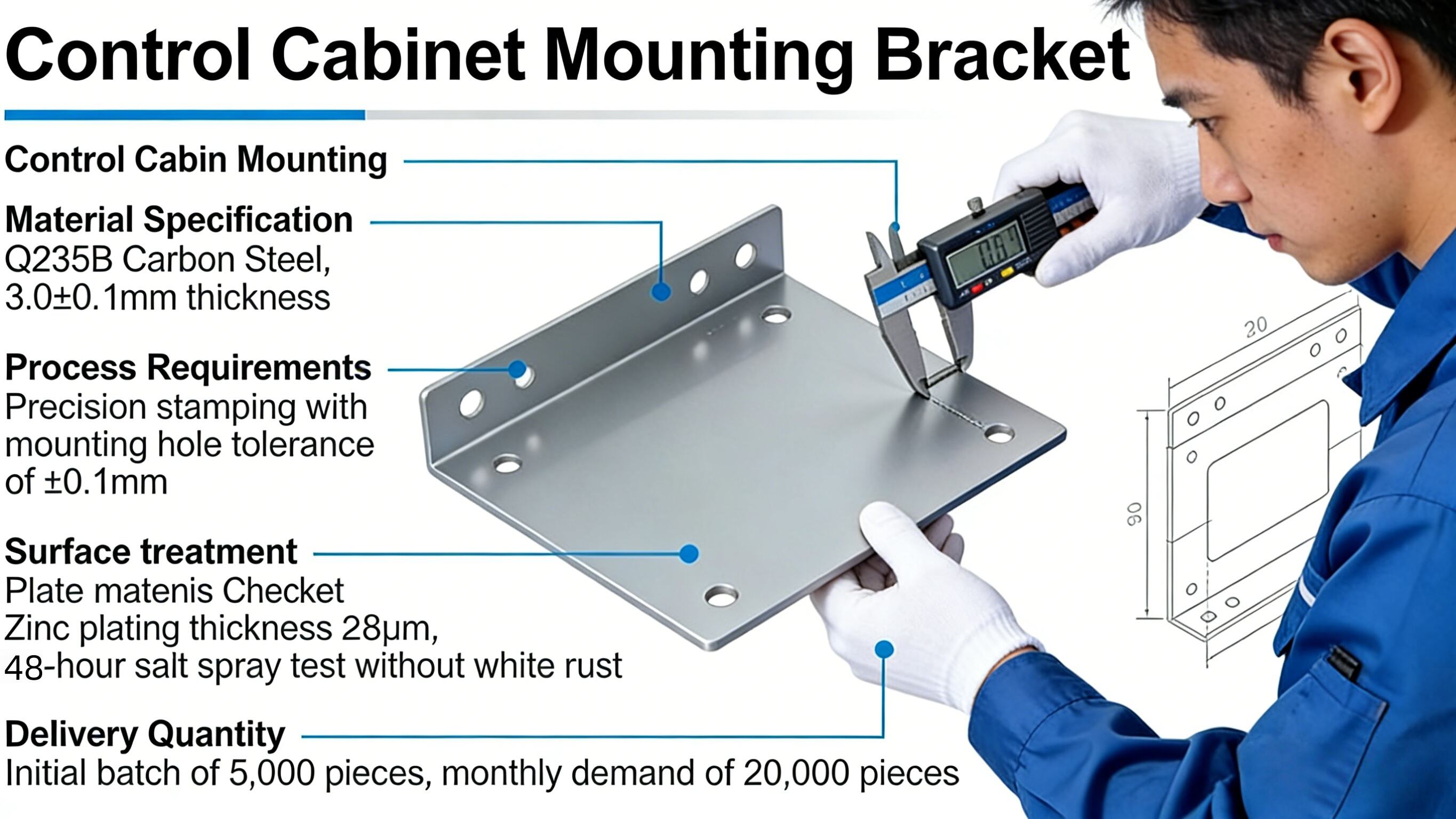

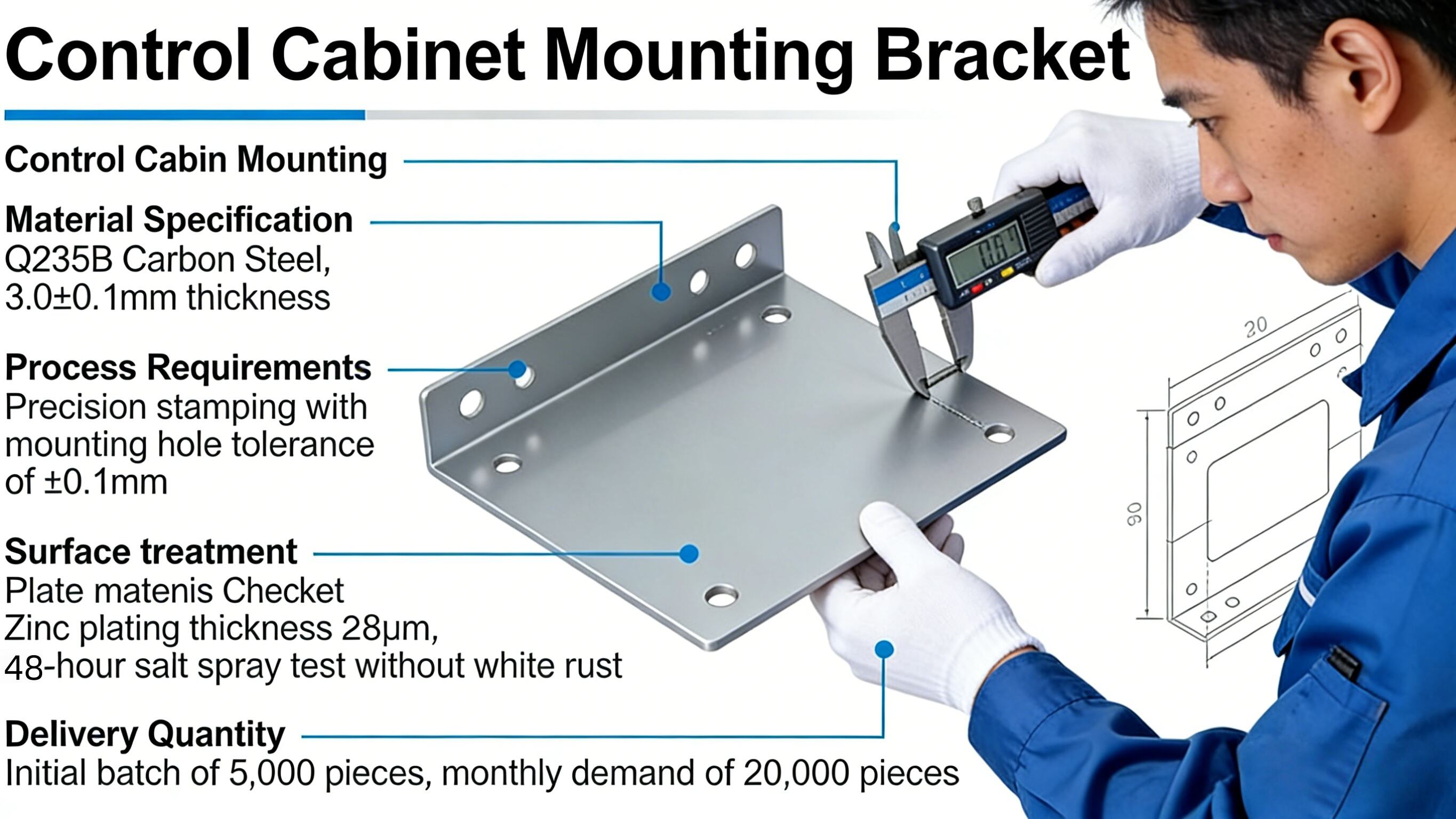

Product Name: Control Cabinet Mounting Bracket

-

Material Specification: Q235B Carbon Steel, Thickness 3.0±0.1mm

-

Process Requirements: Precision stamping forming, mounting hole tolerance ±0.1mm

-

Surface Treatment: Zinc plating thickness ≥8μm, 48-hour salt spray test without white rust

-

Delivery Quantity: Initial batch of 5,000 pieces, monthly demand of 20,000 pieces

Detailed Process Flow

Raw Material Inspection

-

Use a spectrometer to conduct compositional analysis of the carbon steel plates, ensuring compliance with Q235B standards.

- Perform multi-point thickness measurements to guarantee material uniformity.

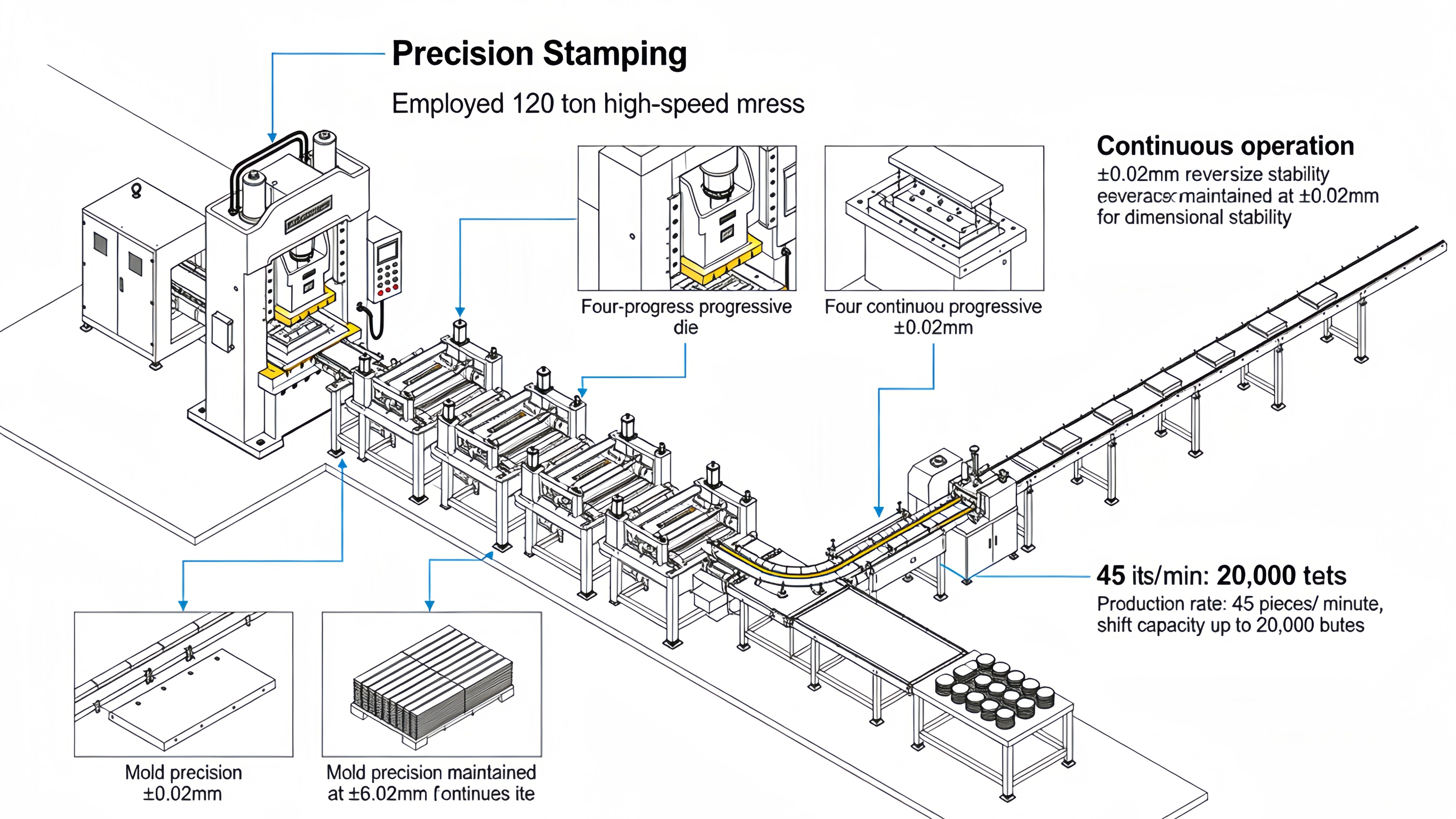

Precision Stamping Forming

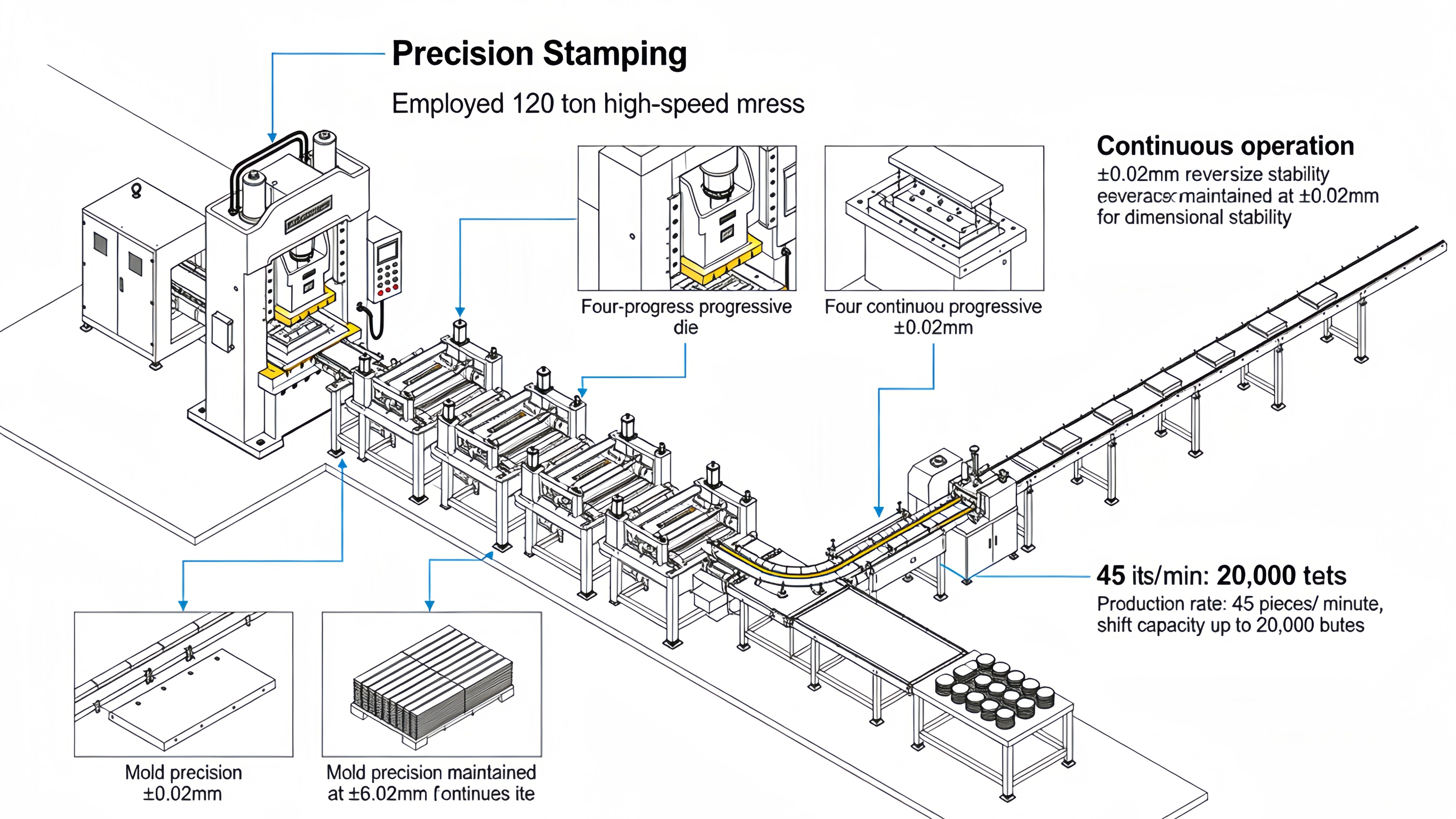

- Utilize a 120-ton high-speed press with a four-stage progressive die for continuous operation.

- Die accuracy reaches ±0.1mm, ensuring product dimensional stability.

-

Production cycle: 25 pieces per minute, shift production capacity of up to 10,000 pieces.

Zinc Plating Surface Treatment

-

Undergo a strict pre-treatment process:

-

Degreasing: Alkaline degreasing agent, temperature 60°C, time 5 minutes.

-

Pickling: Hydrochloric acid concentration 18%, room temperature, time 15 minutes.

-

Zinc Plating: Zinc bath temperature 450°C, immersion time 2 minutes.

-

Passivation: Chromate passivation treatment to enhance anti-corrosion performance.

Quality Assurance Measures

In-Process Inspection

-

First-Article Inspection: Conduct full-dimensional inspection before each shift starts.

-

Patrol Inspection System: Sample and check critical dimensions hourly.

-

Last-Piece Comparison: Retain the final product from each production run as a quality traceability reference.

Finished Product Testing

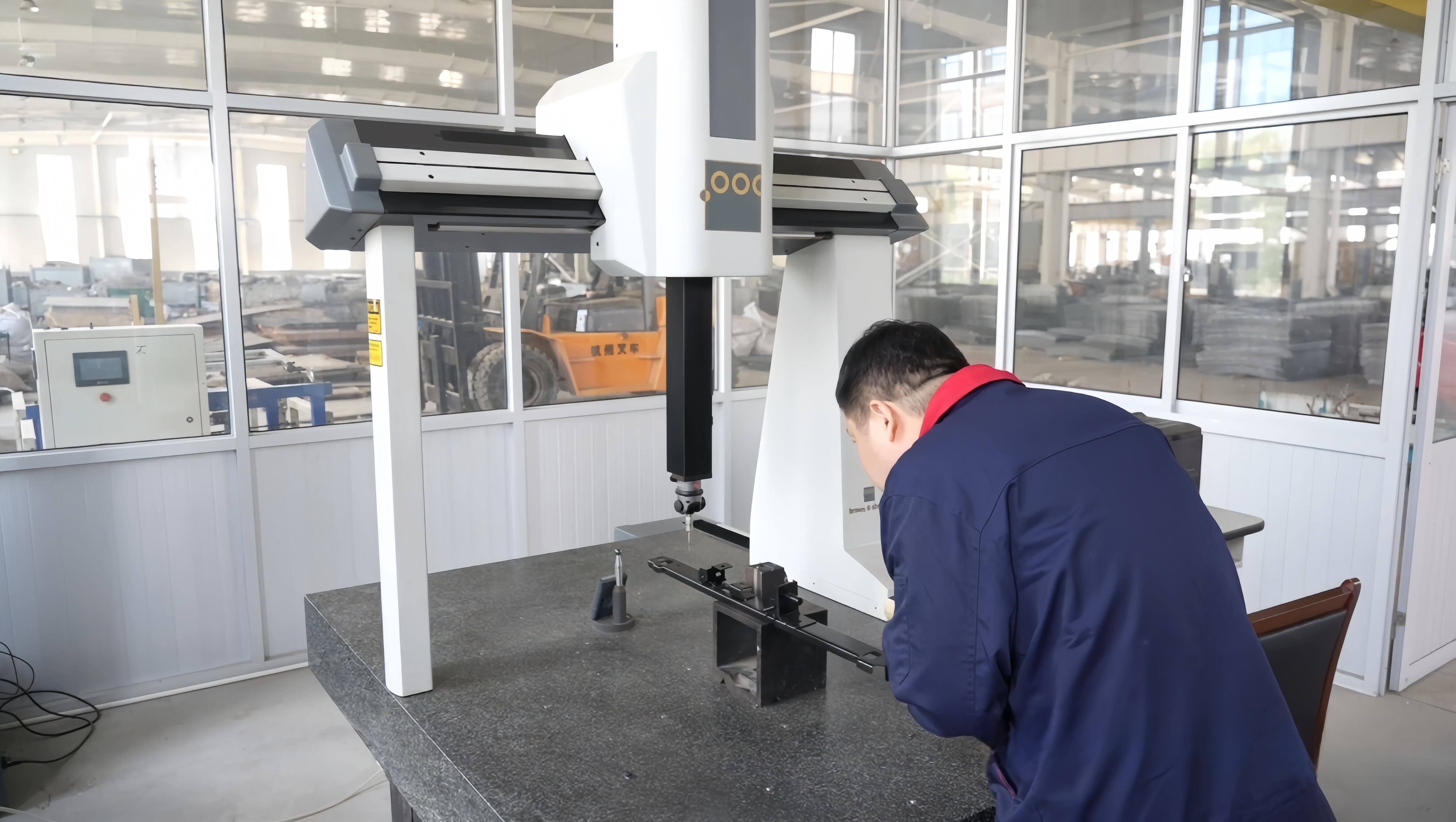

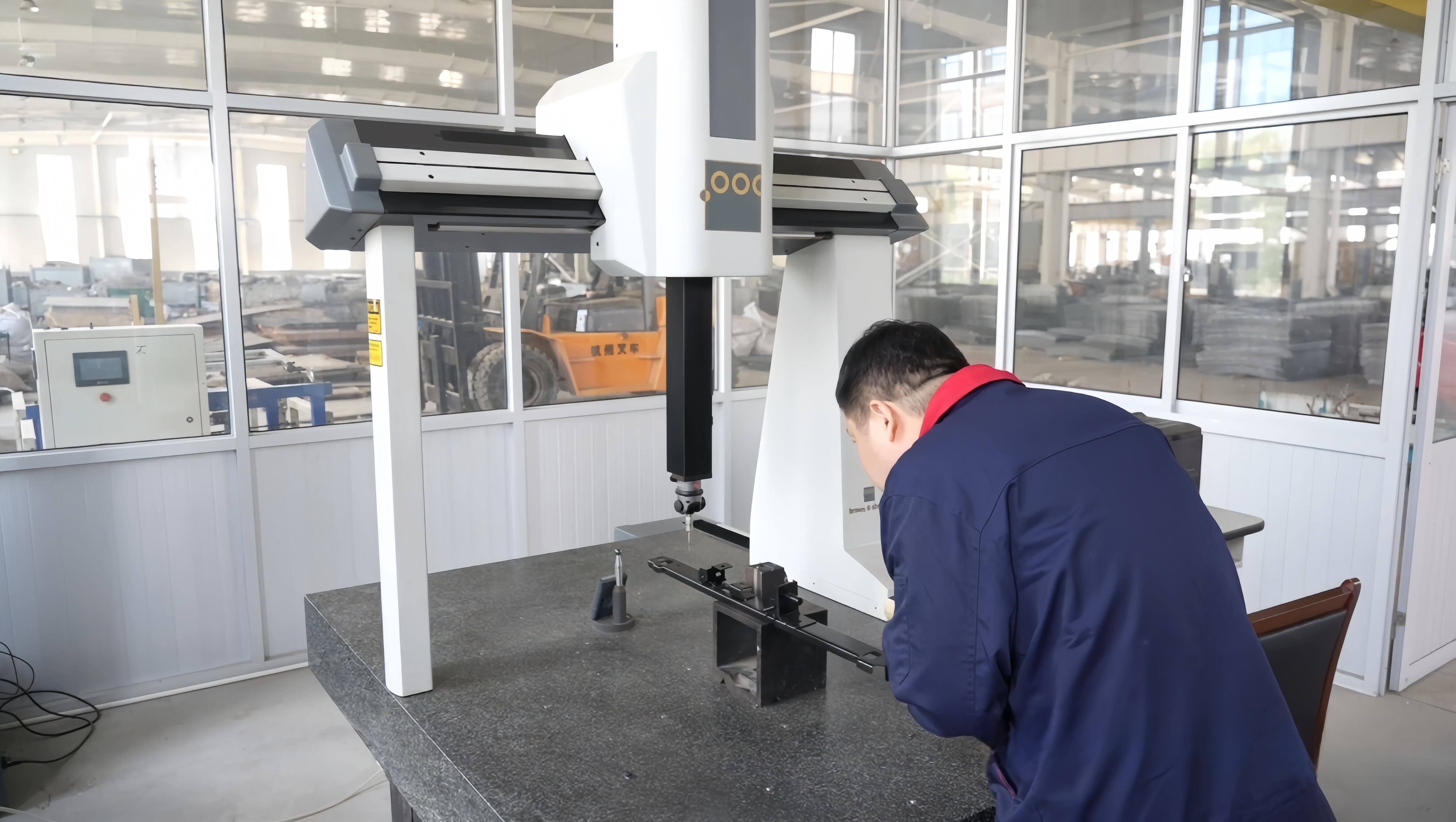

- Use a coordinate measuring machine (CMM) to inspect mounting hole accuracy.

- Employ a zinc coating thickness gauge for multi-point thickness measurement.

- Regularly submit samples to third-party institutions for salt spray corrosion testing.

Final Results and Customer Feedback

The zinc-plated brackets exhibit a uniform blue-white surface with a dense and even coating. During acceptance, the customer particularly praised the following product features:

- Excellent coating quality, free from defects such as missed plating or peeling.

- Mounting hole accuracy fully meets requirements.

- Strong structural stability.

Our Manufacturing Advantages

Through this case, we have demonstrated our professional capabilities in carbon steel component manufacturing:

- Mature zinc plating process expertise.

- Strict quality control system.

- Reliable delivery time assurance.

- Competitive cost control.

We specialize in providing customers with reliable quality and cost-effective metal manufacturing services. For related needs, please feel free to contact us for a solution proposal and quotation.